In the world of FPV (First-Person View) drones, every gram counts—and so does every component. For racers, freestyle pilots, and cinematic flyers, CNC-machined accessories offer unmatched durability, precision, and customization. If you’re building a high-performance drone or upgrading your current rig, here are 7 essential CNC parts that can take your flying experience to the next level.

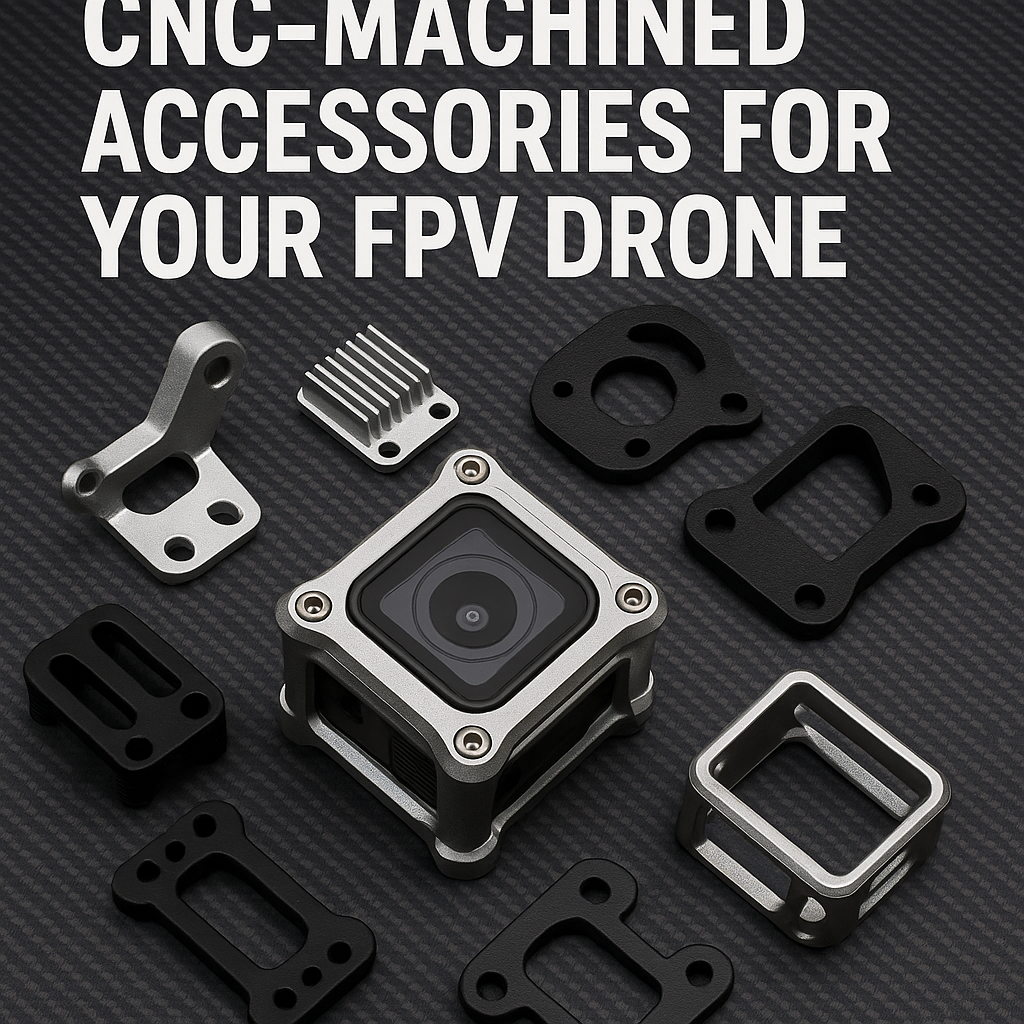

I. CNC Camera Mounts

Your HD camera is one of the most fragile and expensive components on an FPV drone. CNC-machined camera mounts, especially those made from aluminum or carbon fiber, provide robust protection and vibration isolation. Whether you’re flying a GoPro, DJI O3, or Insta360, a custom-fit CNC mount ensures your footage stays stable—even during crashes.

Explore custom CNC parts at Boona Prototypes to create durable and precise mounts that match your drone’s configuration.

II. Precision Antenna Holders

Signal clarity can make or break your flight. CNC-cut antenna mounts help position FPV and receiver antennas at optimal angles for maximum reception. These holders are often lightweight yet rigid, reducing risk of signal dropout while maintaining a clean, aerodynamic build.

Boona Prototypes offers on-demand manufacturing for custom antenna holders tailored to your exact frame layout.

III. Motor Guards

Motors are among the most frequently damaged parts during a crash. CNC-machined motor guards provide a simple yet powerful layer of protection for your drone’s most vulnerable areas. Whether you’re freestyle bashing or racing gates at full speed, these components can save you from costly repairs.

Ask Boona about their low-volume CNC solutions for custom motor protection that fits your frame perfectly.

IV. Landing Skids or Feet

A harsh landing can crack your frame or snap delicate components. CNC-machined skids—made from carbon fiber, Delrin, or aluminum—distribute landing forces while adding just a few grams of weight. They’re ideal for protecting electronics on belly-landed drones and maintaining structural integrity over time.

Learn more about prototyping solutions and material selection that can enhance landing durability.

V. CNC Heat Sinks

Heat buildup in your VTX or ESC can lead to thermal throttling or failure. CNC aluminum heat sinks are precision-milled to match your components and improve airflow, helping to regulate temperature during aggressive flights or long-range sessions.

Boona’s CNC milling services ensure accurate thermal solutions with clean finishes and optional anodizing.

VI. Battery and Strap Plates

Strap mounts and battery plates are crucial for keeping your power source secure during extreme maneuvers. CNC-machined from high-strength materials, these plates prevent battery slippage and wear from repeated use. Chamfered edges reduce strap fraying and sharp contact points.

Work with Boona on custom small-batch manufacturing to match these accessories to your build’s layout.

VII. FPV Camera Cages

Front-end collisions can destroy an FPV camera and leave you grounded. CNC aluminum cages provide the structure and strength to keep your camera safe during impact. They’re especially useful in freestyle builds, where front-facing crashes are more common.

Boona Prototypes supports complex geometries and creative design, allowing you to build a cage that’s protective, light, and stylish.

Final Thoughts

Every FPV drone pilot knows the importance of reliability, and CNC-machined accessories offer exactly that—precision engineering with a pilot’s needs in mind. Whether you’re looking for performance, durability, or style, these seven components are key to maximizing flight quality.

Boona Prototypes stands out as a trusted CNC partner with expertise in carbon fiber, aluminum, and polymer machining for the FPV market. From prototyping to full production, their services are tailored for customization and low-volume, high-precision manufacturing.

👉 Ready to build your next drone with industry-grade parts? Contact Boona Prototypes or reach them via WhatsApp at +86 136 9212 5585 or [email protected].

FAQs

1. Why choose CNC-machined accessories for FPV drones?

CNC machining offers precise tolerances, high strength, and material versatility. These benefits are ideal for custom drone parts that must endure high speeds, vibrations, and crashes.

2. Are CNC accessories better than 3D printed ones?

Yes. While 3D printing is great for prototyping, CNC parts—especially in aluminum or carbon fiber—are much stronger and more heat-resistant, making them better for critical FPV components.

3. What materials are best for CNC drone parts?

Carbon fiber is best for frames; aluminum is great for heat sinks, mounts, and camera cages. Plastics like Delrin or nylon work well for landing gear and lightweight accessories.

4. Can I order custom CNC parts for my drone frame?

Absolutely. Services like Boona Prototypes specialize in low-volume, high-precision custom CNC machining tailored to FPV drone builders and brands.

5. What’s the typical turnaround time for CNC drone parts?

With an efficient rapid prototyping service, turnaround can be as fast as a few days, depending on complexity and order size.

6. Do CNC-machined parts affect drone performance?

Yes, positively. CNC parts provide tighter fits, consistent geometry, reduced vibration, and better thermal performance—leading to smoother, more reliable flights.

7. How do I get a quote for custom CNC drone accessories?

You can contact Boona Prototypes through their website, or directly via WhatsApp: +86 136 9212 5585 or email: [email protected].