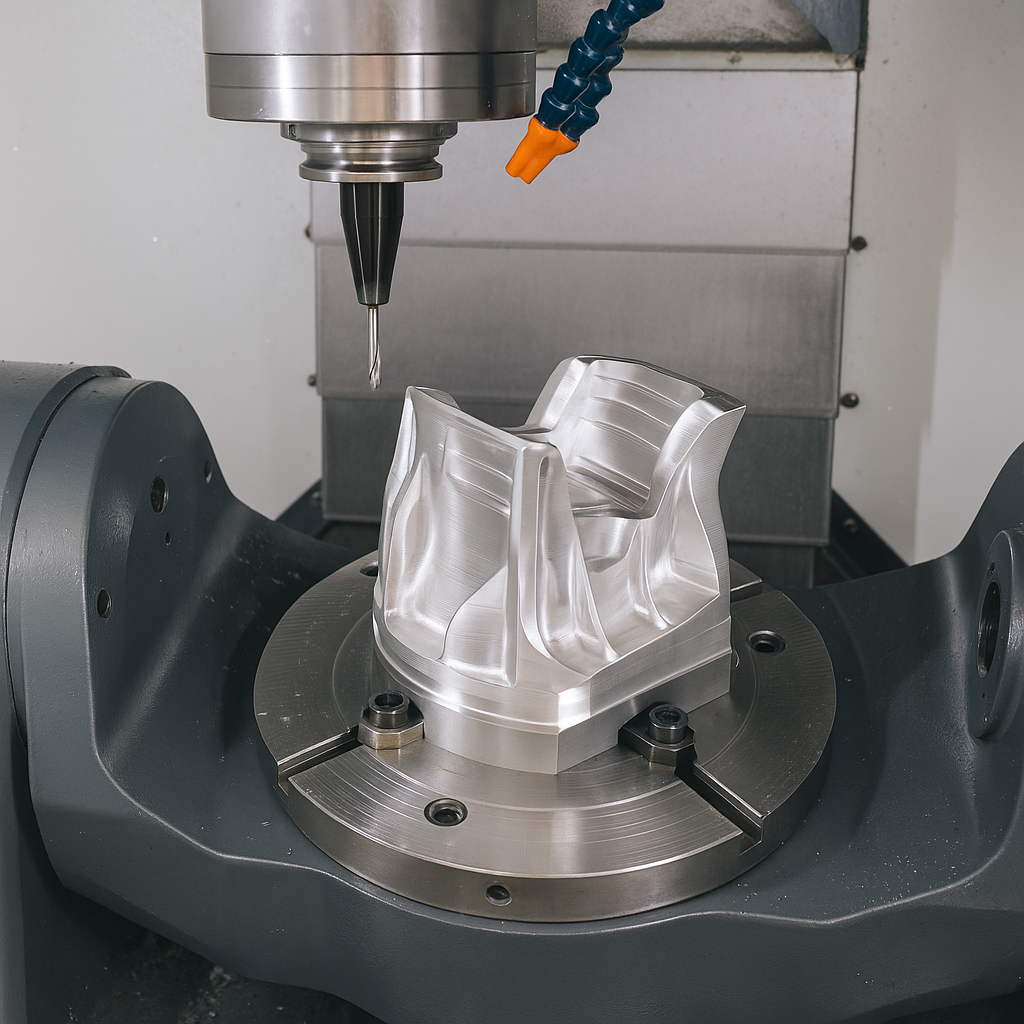

In today’s era of advanced product design, precision and efficiency are non-negotiable. That’s where 5-axis CNC milling shines — a cutting-edge solution enabling engineers and innovators to achieve complex geometries, intricate angles, and high-performance parts in a single setup.

Compared with traditional 3-axis machining, 5-axis CNC milling offers two additional rotational axes, providing a full range of motion that simplifies tool access, reduces setup time, and enhances surface finish.

If you’re looking for an expert partner in this domain, Boona Prototypes is a trusted name with deep expertise and advanced infrastructure tailored for prototype and low-volume precision production.

I. How Does 5-Axis CNC Milling Work?

Unlike conventional 3-axis systems that move along the X, Y, and Z axes, 5-axis CNC machines add two extra axes of rotation. This allows the cutting tool to approach the part from virtually any direction — ideal for undercuts, holes on compound angles, and freeform surfaces.

5-Axis Types:

-

Simultaneous (True) 5-Axis: All five axes move together to maintain tool alignment.

-

3+2 Axis (Positional): The rotational axes orient the part, then the milling occurs in 3 axes.

II. Capabilities Overview (with Table)

Boona Prototypes has invested in high-end 5-axis machining centers, enabling them to handle a wide range of materials and part complexities. Below is a snapshot of their technical capabilities:

| Parameter | Capability |

|---|---|

| Max Part Size | 4000 × 1500 × 600 mm |

| Minimum Feature Size | Ø0.50 mm |

| Tolerances | ±0.01 mm (up to ±0.001 mm on request) |

| Supported Formats | .STEP, .IGES, .STL, .DWG, .DXF, .PDF |

| Typical Turnaround | 3–7 business days |

| CNC Machining Services | Click to explore capabilities |

III. Material Options for 5-Axis CNC Prototyping

Boona supports both metal and plastic materials for 5-axis CNC machining:

Metals:

-

Aluminum 6061, 7075

-

Stainless Steel (304, 316)

-

Titanium, Inconel

-

Brass, Copper

Plastics:

-

PEEK, ABS, Nylon

-

Polycarbonate, Acrylic

-

PTFE, Delrin

IV. Finishing Options Available

Aesthetic and functional surface treatments are a vital part of precision prototypes. Boona offers the following finishing options:

| Finishing Type | Purpose |

|---|---|

| Anodizing (clear/black) | Corrosion resistance, aesthetics |

| Powder Coating | Durable, colored finish |

| Polishing & Brushing | Surface smoothness & appearance |

| Electroless Nickel Plating | Enhanced wear and corrosion resistance |

| Heat Treatment | Improve mechanical properties |

| Surface Finishing Services | Detailed info available |

1. Machine Complex Shapes in One Setup

Fewer setups reduce potential for human error and allow seamless creation of sculpted surfaces, cavities, and compound angles.

2. Improve Surface Finish

Maintaining optimal tool orientation reduces vibration and tool deflection, improving part quality and dimensional accuracy.

3. Boost Efficiency

Save on fixtures, tools, and re-clamping time, which helps compress product development cycles.

4. Scalable for Production

5-axis CNC is not just for prototypes. It’s suitable for small- to mid-batch production runs when integrated with QA and CMM inspection.

VI. Application Scenarios

Boona Prototypes’ 5-axis CNC services are widely used across industries:

-

Aerospace: Engine mounts, turbine blades

-

Medical: Bone implants, surgical tools

-

Automotive: Transmission housings, brackets

-

Consumer Electronics: Structural enclosures, optical mounts

-

Tooling: Complex injection molds

VII. Certifications and Quality Control

Boona ensures world-class quality through certifications:

-

ISO 9001: Quality Management System

-

ISO 13485: Medical Device Manufacturing

-

IATF 16949: Automotive Industry Compliance

Conclusion

If your product requires tight tolerances, complex surfaces, or multi-angle machining, 5-axis CNC milling is the gold standard. It significantly reduces development time while boosting quality and performance.

Partnering with an expert like Boona Prototypes ensures you benefit from industry-best practices, fast delivery, and high-precision output — all tailored to your prototyping needs.

FAQs

1. What is 5-axis CNC milling and how is it different from 3-axis machining?

5-axis CNC milling involves moving a tool or part along five different axes simultaneously, enabling complex geometries and fewer setups compared to traditional 3-axis milling, which moves only in the X, Y, and Z directions.

2. Why should I choose 5-axis CNC machining for prototype development?

5-axis machining allows the production of intricate shapes, undercuts, and curved surfaces in a single setup, reducing lead time and increasing precision—ideal for rapid prototyping and complex part manufacturing.

3. What types of materials can be machined using 5-axis CNC at Boona Prototypes?

Boona supports a wide range of materials including aluminum, stainless steel, titanium, Inconel, brass, as well as plastics like PEEK, ABS, nylon, and polycarbonate.

4. What is the maximum part size and precision Boona can handle?

Boona can mill parts up to 4000 × 1500 × 600 mm and achieve tolerances as tight as ±0.001 mm, depending on material and design.

5. How fast can I get a 5-axis CNC prototype made?

Typical turnaround is 3 to 7 business days, but urgent projects can be expedited. Boona offers quick quotes with DFM support to speed up production.

6. Can Boona Prototypes finish my machined parts?

Yes. Boona offers a range of finishes such as anodizing, bead blasting, powder coating, electroless nickel plating, brushing, and polishing.

7. Is 5-axis CNC machining suitable for low-volume production or only prototyping?

It’s suitable for both. Boona provides on-demand manufacturing for low-volume production and prototyping using 5-axis technology.

8. What file formats does Boona accept for 5-axis CNC machining?

Supported formats include .STEP, .IGES, .STL, .DWG, .DXF, .PDF, and more.

9. What industries benefit most from 5-axis CNC machining?

Industries include aerospace, automotive, medical devices, consumer electronics, and mold tooling, where high-precision and geometric complexity are critical.