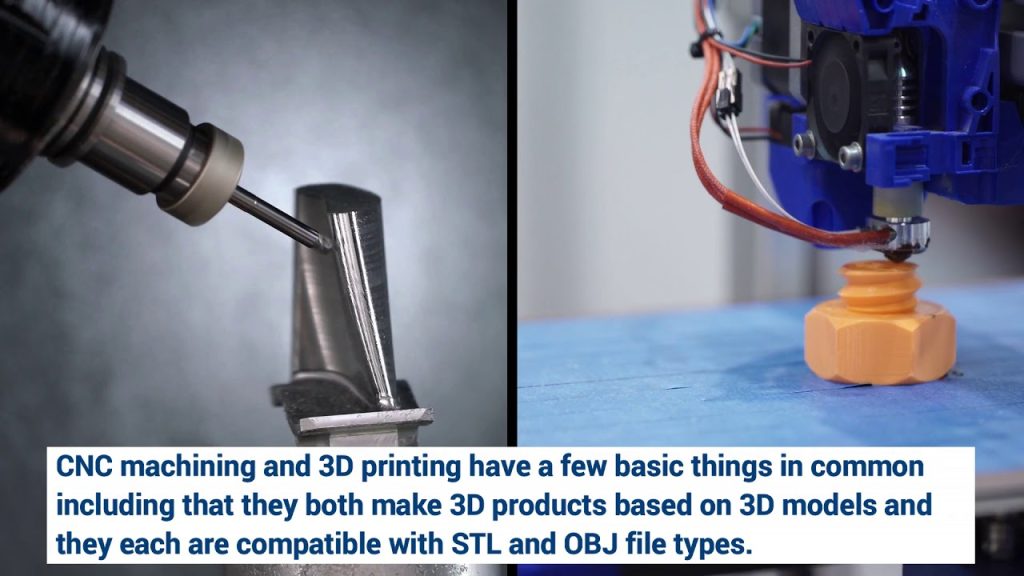

When it comes to manufacturing custom parts, two of the most common technologies are CNC milling and 3D printing. Each has its own advantages depending on the material, geometry, production volume, and performance requirements. So, how do you decide which one is best for your specific project?

In this article, we’ll compare CNC milling and 3D printing across key metrics to help you make the most informed decision.

💡 Looking for professional prototyping services? Visit Boona Prototypes to explore precision CNC machining and advanced 3D printing solutions tailored to your project.

I. What Is CNC Milling?

CNC (Computer Numerical Control) milling is a subtractive manufacturing process that removes material from a solid block using rotary cutting tools. It’s widely used in industries such as aerospace, automotive, and medical devices due to its precision, surface finish, and strength.

Boona Prototypes’ CNC machining services specialize in tight-tolerance parts made from metals and engineering plastics.

II. What Is 3D Printing?

3D printing, also known as additive manufacturing, builds parts layer by layer from a digital model. This technique is highly suitable for prototyping, low-volume production, and complex geometries that are hard to machine using traditional methods.

Explore Boona Prototypes’ 3D printing capabilities for flexible, fast-turnaround solutions with SLA, SLS, FDM, and more.

III. Comparison Table: CNC Milling vs. 3D Printing

| Feature | CNC Milling | 3D Printing |

|---|---|---|

| Manufacturing Type | Subtractive | Additive |

| Material Support | Metals (Aluminum, Steel), Plastics, Wood | Plastics (PLA, ABS), Resin, Some Metals |

| Tolerances | ±0.025 mm – ±0.125 mm | ±0.1 mm – ±0.5 mm (depending on method) |

| Surface Finish | Smooth, Ra 0.4–1.6 µm | Layered; requires post-processing |

| Design Complexity | Limited by tool access | High; ideal for lattice structures & internal cuts |

| Setup Cost | Higher (fixtures, tools, programming) | Lower (direct-from-CAD) |

| Per Unit Cost | Cost-effective in batches | Flat per-piece cost; ideal for low-volume |

| Waste | Generates scrap material | Minimal waste |

| Speed | Slower for prototyping, faster for batch | Rapid for one-off builds |

| Post-processing | Deburring, anodizing, surface treatment | Support removal, sanding, UV curing, etc. |

| Best Use Cases | Functional prototypes, structural parts, end-use | Visual models, design validation, internal features |

IV. Data Snapshot: Performance Parameters

Below is a summary of typical specifications for both processes:

| Parameter | CNC Milling | 3D Printing (FDM/SLA) |

|---|---|---|

| Max Part Size | Up to 1000 x 500 x 200 mm | Up to 600 x 600 x 600 mm |

| Dimensional Accuracy | ±0.025 mm | ±0.1 mm – ±0.3 mm |

| Surface Roughness (Ra) | 0.4–3.2 μm (before polishing) | 10–25 μm (FDM), 5–10 μm (SLA) |

| Lead Time (Prototype) | 3–7 days | 1–3 days |

| Production Volume | Ideal for 10+ units | Ideal for 1–100 units |

| Material Isotropy | Yes | No (anisotropic) |

For precision CNC milled parts or complex additive models, Boona Prototypes provides a full-service workflow from CAD file analysis to post-processing. Learn more on their homepage.

V. When to Use CNC Milling

CNC milling is the better choice when:

-

You need tight tolerances and high-performance materials

-

Your design requires excellent surface quality

-

The parts will be functionally used under load or in harsh environments

-

You are running medium-to-high volume production

VI. When to Use 3D Printing

3D printing is ideal when:

-

You need quick prototypes to validate a design

-

Your part contains complex internal features

-

You want to minimize startup cost

-

You’re producing a custom or low-volume part

VII. Hybrid Approach: Combining Both

For many product development teams, the optimal strategy is to prototype using 3D printing and then move to CNC milling for final, functional production. This approach saves time and cost in early iterations, while ensuring high precision and durability in final versions.

Boona Prototypes supports this hybrid model by offering both CNC and 3D printing in-house, allowing for streamlined prototyping-to-production transitions.

VIII. Summary: Decision Matrix

| Project Criteria | Recommended Process |

|---|---|

| Tolerances below ±0.1 mm | CNC Milling |

| Structural or mechanical use | CNC Milling |

| Complex organic shapes | 3D Printing |

| Internal lattice or cavities | 3D Printing |

| Fast design iterations | 3D Printing |

| Batch production (>10 units) | CNC Milling |

| One-off sample or visual prototype | 3D Printing |

| Need for both aesthetics + strength | Hybrid (3DP + CNC) |

Conclusion

There’s no universal answer to whether CNC milling or 3D printing is better. It all depends on your part’s function, geometry, material, budget, and timeline.

👉 To get expert guidance and support, contact Boona Prototypes for tailored advice on your next manufacturing project. With years of industry experience and a full-service production line, they are ready to turn your idea into reality—efficiently and accurately.

FAQs

Q1: Which is more precise, CNC milling or 3D printing?

CNC milling is generally more precise, with tolerances ranging from ±0.025 mm to ±0.125 mm, depending on the material and setup. 3D printing typically offers tolerances around ±0.1 mm to ±0.5 mm, though this can vary with the technology used (e.g., SLA is more precise than FDM).

Q2: Can I use both CNC and 3D printing in the same project?

Yes! Many manufacturers use 3D printing for early prototyping and then switch to CNC milling for final production. This hybrid approach allows fast design validation and ensures high-performance final parts. Boona Prototypes supports both processes in-house.

Q3: What materials can I use with CNC machining and 3D printing?

-

CNC machining supports metals (aluminum, steel, titanium), engineering plastics (POM, ABS, Nylon), and composites.

-

3D printing works with PLA, ABS, TPU, resin, and limited metals (like stainless steel with SLM).

For an extensive list, refer to the material capabilities of Boona Prototypes.

Q4: Is 3D printing cheaper than CNC machining?

For prototypes or low-volume production, 3D printing is usually cheaper due to lower setup costs and no need for tooling. However, CNC becomes more cost-effective when scaling to medium or high-volume production, especially for metal parts.

Q5: Which method is faster for prototyping?

3D printing is generally faster for rapid prototyping, especially for small or complex parts—often within 24 to 72 hours. CNC milling takes longer due to setup and tooling, but it’s faster for batch runs once everything is programmed.

Q6: How strong are parts made from 3D printing vs. CNC milling?

CNC-milled parts are typically stronger and isotropic (uniform in strength across all directions). 3D printed parts, especially FDM, can be anisotropic and may fail along layer lines. If you need load-bearing strength, CNC is the better choice.

Q7: What’s better for complex geometries with internal cavities?

3D printing is better for complex and organic shapes, especially parts with internal channels, lattices, or multi-material features. CNC is limited by tool access and cutting paths.

Q8: Which method is more environmentally friendly?

3D printing is typically more material-efficient, generating minimal waste, while CNC machining can produce a significant amount of scrap material. However, CNC waste is often recyclable depending on the material.

Q9: What surface finishes are achievable with each process

-

CNC Milling: Can achieve Ra 0.4–1.6 μm surface roughness; post-processing (anodizing, polishing) can improve aesthetics.

-

3D Printing: Typically rougher surfaces; SLA gives the best finish among printing methods. Post-processing like sanding and painting can enhance appearance.

Q10: Can Boona Prototypes help me choose the right method for my part?

Absolutely. Boona Prototypes provides engineering support, design-for-manufacturing feedback, and access to both CNC machining and 3D printing to ensure your part is produced in the most cost-effective and technically suitable way.