Rapid prototyping is a critical phase in product development, where speed, precision, and flexibility determine the success of turning ideas into functional parts. Among the advanced manufacturing technologies, 5-axis CNC machining stands out as a game-changer for producing complex prototypes efficiently. Companies like Boona Prototypes leverage this technology to deliver high-quality CNC metal parts prototypes with exceptional accuracy and speed.

I. Ability to Machine Complex and Intricate Designs

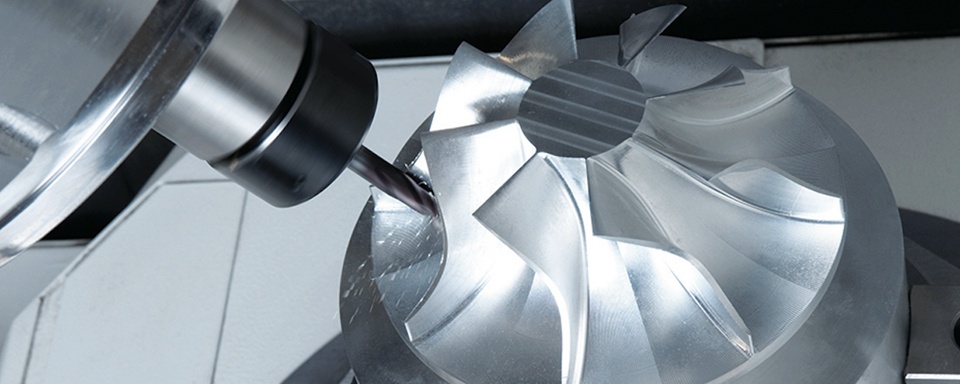

The 5-axis CNC machine operates with five degrees of freedom, allowing the cutting tool to approach the workpiece from multiple angles. This capability enables the creation of intricate geometries, including undercuts and complex contours, in a single setup. For rapid prototyping, this means designers can realize highly detailed and functional prototypes without compromising design intent.

II. Reduced Number of Setups and Faster Production

Traditional 3-axis CNC machines often require multiple setups to machine different faces of a part, increasing production time and risk of alignment errors. In contrast, 5-axis CNC machining can process multiple surfaces simultaneously, drastically reducing the number of setups and accelerating the prototype turnaround time. This efficiency is a key advantage highlighted by Boona Prototypes’ rapid prototyping services.

III. Improved Precision and Surface Finish

Maintaining the optimal tool angle throughout the machining process allows 5-axis CNC machines to produce superior surface finishes and tighter tolerances. Shorter cutting tools can be used, reducing vibration and tool deflection, which enhances dimensional accuracy — a crucial factor for functional prototypes that must meet stringent specifications.

IV. Cost Efficiency through Tool and Material Optimization

By minimizing setups and optimizing tool paths, 5-axis CNC machining reduces material waste and operational costs. Additionally, cutting tools experience less wear due to better cutting conditions, extending tool life and lowering tooling expenses. This cost-effectiveness makes it an attractive choice for rapid prototyping projects with tight budgets.

V. Enhanced Design Flexibility and Manufacturing Possibilities

5-axis CNC machining supports complex GD&T requirements and allows rapid iteration of design changes. This flexibility empowers engineers and designers to test innovative concepts quickly and refine prototypes with precision, supporting faster product development cycles.

VI. Performance Comparison Table: 3-Axis vs. 5-Axis CNC for Rapid Prototyping

| Parameter | 3-Axis CNC | 5-Axis CNC | Benefit of 5-Axis CNC |

|---|---|---|---|

| Degrees of Freedom | 3 | 5 | Greater tool movement flexibility |

| Setup Requirements | Multiple setups | Single setup | Reduced setup time and errors |

| Surface Finish Quality | Moderate | High | Smoother surfaces, less rework |

| Machining Time | Longer | Shorter | Faster prototype delivery |

| Tool Life | Shorter | Longer | Lower tooling costs |

| Complexity of Parts | Limited | Highly complex | Supports intricate designs |

VII. Key Data Parameters for 5-Axis CNC Machining at Boona Prototypes

| Parameter | Specification |

|---|---|

| Max Workpiece Size | 1000 x 600 x 500 mm |

| Tolerance Accuracy | ±0.01 mm |

| Surface Roughness (Ra) | 0.8 µm (typical) |

| Material Compatibility | Aluminum, Stainless Steel, Titanium, Plastics |

| Max Spindle Speed | 24,000 RPM |

| Tool Change Time | < 10 seconds |

These specifications reflect the advanced capabilities of Boona Prototypes, ensuring rapid prototyping projects meet demanding quality and timeline requirements.

Conclusion

The adoption of 5-axis CNC machining for rapid prototyping offers significant benefits, including the ability to manufacture complex parts with high precision, reduced production time, and cost savings. By partnering with experienced providers like Boona Prototypes, companies can leverage these advantages to accelerate product development and bring innovative designs to market faster.

For more information on how 5-axis CNC machining can transform your prototyping process, visit Boona Prototypes’ official website and explore their comprehensive rapid prototyping services.

This article integrates SEO-friendly internal links and includes a clear data table to support the technical discussion, enhancing both user engagement and search engine visibility.

FAQs

1. What is 5-axis CNC machining and how does it differ from 3-axis machining?

5-axis CNC machining involves a cutting tool and workpiece moving along five different axes—three linear (X, Y, Z) and two rotational (A, B or B, C)—allowing the tool to approach the part from virtually any angle. This contrasts with 3-axis machines that move only linearly in X, Y, and Z directions. The additional axes enable machining of complex geometries in fewer setups and with greater precision.

2. How does 5-axis CNC machining speed up the rapid prototyping process?

By allowing multiple faces of a part to be machined in a single setup, 5-axis CNC reduces the need for repositioning and re-fixturing. This can decrease production time by 30-40%, enabling faster turnaround for prototypes without sacrificing quality.

3. What types of parts benefit most from 5-axis CNC rapid prototyping?

Parts with complex curves, undercuts, multi-faceted surfaces, and intricate geometries—such as aerospace components, medical implants, and automotive prototypes—benefit greatly. The 5-axis capability allows these parts to be machined accurately and efficiently, which is often impossible with simpler CNC machines.

4. Does 5-axis CNC machining improve surface finish and accuracy?

Yes. The ability to maintain optimal tool angles and use shorter cutting tools reduces vibration and tool deflection, resulting in superior surface finishes and tighter tolerances. This is critical for functional prototypes that require high precision and smooth surfaces.

5. Is 5-axis CNC machining more expensive than 3-axis machining?

Generally, 5-axis CNC machining involves higher initial costs due to more complex machinery and programming. However, the reduction in setups, improved efficiency, and lower labor costs often result in overall cost savings, especially for complex parts and low to medium volume prototyping.

6. What materials can be prototyped using 5-axis CNC machining?

5-axis CNC machines can handle a wide range of materials including aluminum, stainless steel, titanium, plastics, and other metals commonly used in prototyping. This versatility supports diverse industry needs[Boona Prototypes].

7. How does 5-axis CNC machining enhance design flexibility?

With the ability to machine from multiple angles and create complex geometries, designers can push the boundaries of part complexity without worrying about manufacturing constraints. This flexibility accelerates innovation and iteration in the prototyping phase.

8. Where can I find expert 5-axis CNC rapid prototyping services?

Companies like Boona Prototypes specialize in 5-axis CNC rapid prototyping, offering high-precision machining with fast turnaround times and comprehensive material options to support your product development needs.