In today’s fast-paced and precision-driven manufacturing environment, choosing the right mold manufacturing partner is critical. Whether you’re in automotive, medical, consumer electronics, or robotics, your mold supplier plays a pivotal role in your product’s quality, cost, speed-to-market, and long-term performance. In this article, we’ll explore the key criteria to consider when selecting a reliable mold manufacturing partner—and how Boona Prototypes stands out as a leader in the industry.

I. Understand Your Project Requirements

Start by identifying your specific needs:

-

Part geometry and complexity

-

Material types (e.g., ABS, PC, POM, Silicone)

-

Production volume

-

Tolerances and surface finish

These details form the foundation for evaluating whether a mold manufacturer can meet your technical specifications and cost targets.

II. Industry Experience and Certifications Matter

Look for a mold maker with a proven track record in your field. For instance, Boona Prototypes is certified under ISO 9001, ISO 13485, and IATF 16949, ensuring compliance with stringent quality and industry standards.

| Certification | Industry Relevance |

|---|---|

| ISO 9001 | General Quality Management |

| ISO 13485 | Medical Device Manufacturing |

| IATF 16949 | Automotive Quality Systems |

III. Mold Making Capabilities at a Glance

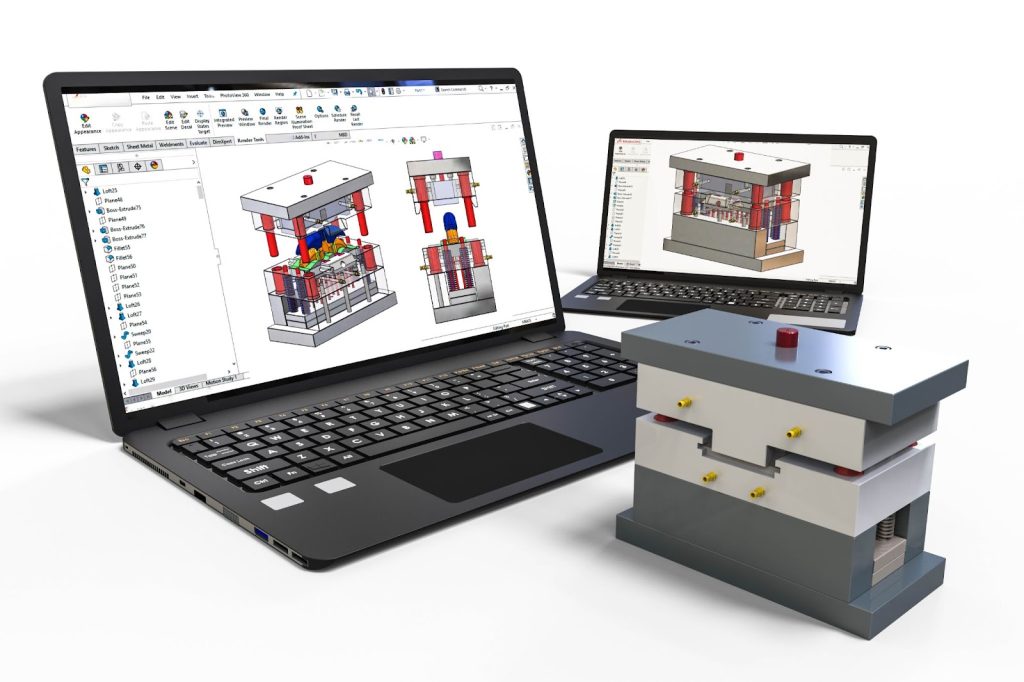

When comparing mold manufacturers, consider their machining accuracy, tool life, lead time, and flexibility in mold design.

Boona’s Mold Manufacturing Capabilities:

| Specification | Value |

|---|---|

| Mold Tooling Lead Time | 15–25 days |

| Tolerance | ±0.005 mm |

| Mold Base Material | Steel, Aluminum |

| Supported Mold Types | LSR Molds, Multi-cavity, Overmold |

| Minimum Production Volume | Prototype to Mass Production |

| Surface Finishes Supported | SPI A1–D3, VDI 3400, EDM |

Learn more about silicone molding at Boona — ideal for flexible, biocompatible components.

IV. DFM Engineering and Design Support

A quality mold partner doesn’t just build what you provide—they help optimize your designs. Boona Prototypes offers free DFM feedback within 24 hours, mold flow simulation, and design optimization services to reduce production costs and extend tool life.

V. Speed and Flexibility in Production

Time-to-market can make or break a product launch. Boona supports rapid prototyping, bridge tooling, and high-volume production, giving clients flexibility at every stage of the product lifecycle.

| Production Stage | Typical Lead Time |

|---|---|

| Rapid Prototyping | 2–3 Days (SLA/3D) |

| Soft Tooling (Aluminum) | 7–12 Days |

| Hard Tooling (Steel) | 15–25 Days |

| T1 Sample Delivery | Within 3–5 Days of Mold Completion |

Explore CNC machining services for custom aluminum or steel molds with high repeatability and fast turnaround.

VI. Transparent Pricing and Mold Ownership

Clarify early on:

-

Who owns the mold?

-

Are there maintenance or storage fees?

-

Can the mold be transferred?

Boona offers full transparency on mold ownership and lifetime support for modifications or future production.

VII. Strong Communication and Project Management

Effective communication ensures faster iteration and fewer errors. Boona assigns a dedicated project manager for each client, providing regular updates, visual progress reports, and fast response times.

VIII. Intellectual Property (IP) and Risk Control

Protect your designs and data:

-

Sign NDAs before sharing CAD files

-

Work with companies that keep molds in secure facilities

Boona’s data handling practices comply with international standards and offer secure upload portals for CAD models and technical drawings.

IX. Long-Term Support and Lifecycle Management

From first article inspection (FAI) to post-launch modifications, the right partner offers ongoing support. Boona includes mold maintenance, polishing, and repair services throughout the mold’s life.

Why Boona Prototypes is the Right Partner for Mold Manufacturing

Boona isn’t just a service provider—it’s a strategic partner in mold development. Here’s why companies around the world choose Boona:

✅ Fast quote turnaround (within 24 hours)

✅ Ultra-precise CNC machining and EDM tooling

✅ Rapid delivery of T1 samples

✅ Full range of surface finishes and material compatibility

✅ ISO, IATF-certified systems for quality control

✅ Transparent pricing and full mold ownership

✅ Expertise in silicone molds, low-volume production, and complex parts

Conclusion

Selecting the right mold manufacturing partner involves more than just comparing prices. It’s about finding a company that aligns with your technical needs, quality expectations, timeline, and values. Boona Prototypes offers world-class capabilities across every stage of mold development—from DFM to final delivery—making them a trusted partner for companies seeking speed, precision, and reliability in manufacturing.

FAQs

Q1: What should I look for in a mold manufacturing partner?

Key criteria include industry certifications (like ISO 9001, ISO 13485, or IATF 16949), mold-making experience, precision capabilities (e.g., tolerances of ±0.005 mm), engineering support such as DFM analysis, and a proven track record of timely delivery. Trusted partners like Boona Prototypes also offer transparency in pricing and mold ownership.

Q2: Why is ISO certification important for mold manufacturers?

ISO certifications ensure that the manufacturer follows strict quality control systems. For example, Boona Prototypes is certified under ISO 9001 for quality management, ISO 13485 for medical devices, and IATF 16949 for automotive production—making them a reliable choice across multiple sectors.

Q3: How fast can I get a mold and sample parts made?

Lead times depend on mold complexity and material, but Boona typically delivers aluminum tooling in 7–12 days and steel molds in 15–25 days. First article samples (T1) are often shipped within 3–5 days after mold completion.

Q4: What is DFM, and why does it matter?

DFM (Design for Manufacturability) ensures your part is optimized for moldability, cost-efficiency, and long-term performance. Boona Prototypes provides free DFM feedback within 24 hours to help clients refine their designs before tool production begins.

Q5: Can Boona Prototypes produce both prototype and production molds?

Yes, Boona supports low-volume prototyping using rapid tooling and scalable production using hardened steel molds, including multi-cavity, overmolding, and insert molds. Their CNC machining services enable precision mold base manufacturing.

Q6: Who owns the mold after manufacturing?

With reputable partners like Boona, clients retain full ownership of the mold. This is crucial for IP protection and future production flexibility.

Q7: What surface finish options are available for molded parts?

Boona supports a wide range of industry-standard finishes, including SPI A1–D3, VDI 3400 textures, EDM patterns, and custom polishing—essential for cosmetic and functional applications. See more in their surface finishing services.

Q8: Can Boona handle medical- or food-grade molding requirements?

Yes. With ISO 13485 certification and experience in LSR (Liquid Silicone Rubber) and FDA-compliant materials, Boona is equipped to meet strict requirements for medical, dental, and consumer safety parts. Learn more on their silicone molding page.

Q9: How does Boona ensure quality during production?

Boona uses in-process inspection, first article approval, CMM measuring tools, and detailed quality reports. Their certified QC process ensures every mold and part meets client specifications before shipment.

Q10: Does Boona offer post-mold services?

Yes. Boona offers mold maintenance, repairs, polishing, and support for future modifications or repeat production—ensuring your tooling investment lasts.