The electric vehicle (EV) market is evolving at an unprecedented pace. Consumers demand higher performance, better range, and innovative designs, while manufacturers face intense competition to bring these improvements to market faster than ever.

In this environment, CNC prototyping has emerged as a critical enabler of rapid, precise, and cost-effective EV innovation.

Companies like BOONA Prototypes specialize in delivering on-demand CNC machining and prototyping services—with high precision (±0.01 mm), fast turnaround, and a wide range of materials—helping EV manufacturers cut lead times from months to days.

I. Speed & Iteration in EV Development

In EV design, time-to-market is everything. CNC prototyping allows engineers to go from CAD file to finished part in as little as 3 days—a massive advantage over traditional manufacturing, which often requires tooling and setup delays.

At BOONA Prototypes, streamlined workflows and 1-on-1 engineering support ensure that design iterations happen quickly, allowing rapid testing and refinement.

II. Precision for Performance

High-performance EV components—like battery enclosures, motor housings, and cooling systems—demand tight tolerances to function efficiently and safely. CNC machining delivers repeatable accuracy, ensuring that every prototype matches the final production part.

Table 1: CNC Machining Precision Capabilities at BOONA

| Parameter | Specification |

|---|---|

| Tolerance | ±0.01 mm |

| Maximum Part Size | 2000 × 1500 × 300 mm |

| Minimum Feature Size | 0.25 mm |

| Surface Finish (Ra) | 0.8 μm |

| Supported Axes | 3, 4, and 5-axis |

| Production Lead Time | 3–7 days |

EV design often requires lightweight yet strong materials for efficiency and range optimization. CNC machining offers flexibility across metals and plastics, enabling manufacturers to choose the optimal material for each part.

Table 2: Common CNC Materials for EV Components

| Material | Key Benefits for EV Parts |

|---|---|

| Aluminum 6061 | Lightweight, corrosion-resistant, excellent heat dissipation |

| Stainless Steel 304 | High strength, wear resistance, long durability |

| Copper | Exceptional conductivity for battery connectors |

| PEEK Plastic | High-temperature resistance for under-hood components |

| ABS Plastic | Cost-effective for non-structural prototypes |

You can explore BOONA material options to match your project’s requirements.

IV. Complex Geometries Without Tooling Delays

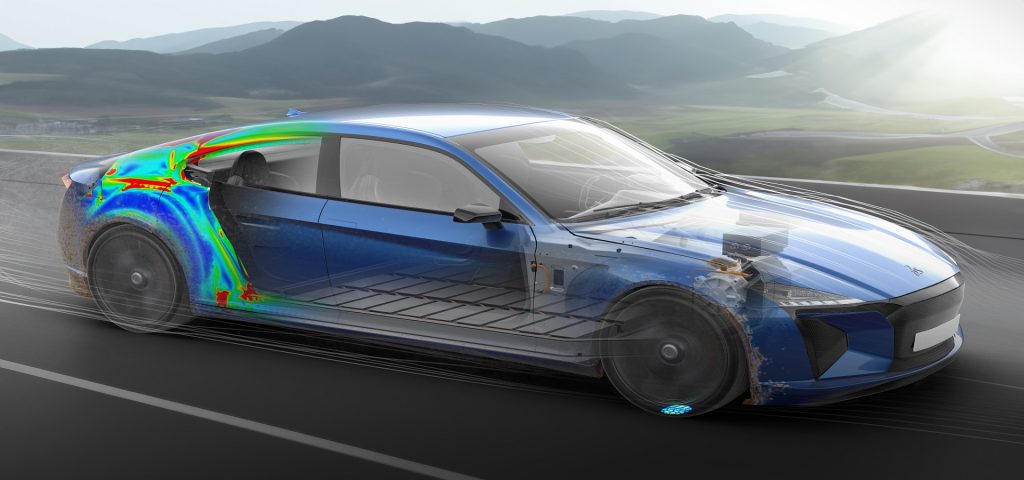

Modern EV parts often require intricate geometries—from cooling channels in battery plates to aerodynamic enclosures. Multi-axis CNC machining can create these complex shapes in one setup, eliminating the need for expensive molds in early development.

At BOONA, 5-axis CNC capabilities allow for machining of undercuts, compound curves, and tight internal features without additional tooling, accelerating innovation cycles.

V. Real-World Applications in EV Components

CNC prototyping supports critical EV innovations, including:

-

Battery enclosures & cooling plates: High-precision aluminum parts improve thermal management.

-

Motor housings & drivetrain parts: Accurate fits ensure efficiency and low noise.

-

Charging connectors: CNC enables rapid iteration of connector designs for safety and compatibility.

-

Structural brackets: Durable, lightweight components reduce vehicle weight.

VI. Integration with Digital Prototyping

By pairing CNC with CAD modeling and virtual testing, engineers can detect and fix design flaws before production. BOONA offers free manufacturability analysis, ensuring parts are optimized for CNC production—saving both time and cost.

VII. Business Benefits for EV Startups & Manufacturers

-

No minimum order quantity (MOQ): Ideal for low-volume prototyping.

-

Scalable production: Transition from prototypes to mass production seamlessly.

-

ISO 9001 quality control: Each part comes with inspection reports and material certifications.

-

Global delivery: Serving clients worldwide, with reliable logistics.

Conclusion

CNC prototyping is transforming EV development—enabling faster design cycles, higher precision, and broader material choices. With providers like BOONA Prototypes offering fast turnaround, advanced CNC capabilities, and expert engineering support, EV innovators can bring new ideas from concept to road in record time.

By leveraging CNC technology early in the design process, EV companies can not only accelerate product launches but also maintain quality and safety standards—paving the way for a more sustainable and competitive future in electric mobility.

FAQs

Q1: What is CNC prototyping, and why is it important for EV manufacturing?

CNC prototyping uses computer-controlled machines to create precise parts directly from CAD designs. For electric vehicle (EV) manufacturing, it enables rapid iteration, tight tolerances, and the ability to test functional prototypes before committing to mass production. Companies like BOONA Prototypes provide these services with high accuracy (±0.01 mm) and fast turnaround.

Q2: How does CNC prototyping speed up EV development timelines?

Unlike traditional manufacturing methods that require molds or tooling, CNC machining can produce parts in just a few days. This means EV designers can move from concept to physical testing faster, significantly reducing the product development cycle.

Q3: What materials can be used for CNC prototyping in EV components?

CNC machining supports a wide variety of materials, including aluminum, stainless steel, copper, PEEK, and ABS plastic. Each material serves different purposes—lightweight aluminum for battery enclosures, stainless steel for strength, or PEEK for high-temperature resistance. BOONA material list covers many options for EV projects.

Q4: Can CNC machining handle complex EV part designs?

Yes. Multi-axis CNC machines (such as 5-axis systems) can produce intricate geometries, undercuts, and compound curves in one setup—perfect for EV cooling plates, aerodynamic parts, and structural components.

Q5: Is CNC prototyping cost-effective for small EV startups?

Absolutely. CNC services from BOONA Prototypes have no minimum order quantity (MOQ), making them ideal for low-volume production runs and prototypes. This avoids the high costs of tooling required in other manufacturing methods.

Q6: How does CNC prototyping improve EV part quality?

With tolerances as tight as ±0.01 mm and ISO 9001-certified quality checks, CNC machining ensures that each prototype matches production-level standards—critical for safety, performance, and durability in EV applications.

Q7: Can CNC prototyping be integrated with other manufacturing methods?

Yes. CNC is often combined with additive manufacturing (3D printing) and injection molding for hybrid prototyping workflows. This flexibility allows manufacturers to choose the best method for each stage of EV development.