In modern manufacturing, custom fixtures and jigs are critical for efficiency, accuracy, and repeatability. Traditionally, these tools were made through machining, welding, or other subtractive methods. However, the rise of 3D printing services has transformed the way companies design and produce fixtures and jigs, enabling faster turnaround, lower costs for small batches, and highly customized solutions.

For companies seeking a reliable partner, Boona Prototypes offers professional 3D printing services with multiple technologies, materials, and fast lead times suitable for industrial applications.

I. Why Fixtures and Jigs Matter in Manufacturing

-

Fixtures hold parts in place during machining or assembly.

-

Jigs guide the tools to ensure accuracy and consistency.

-

Together, they reduce errors, speed up production, and improve safety.

When designed with 3D printing, these aids become more cost-effective, ergonomic, and tailored to specific workflows.

II. 3D Printing Technologies for Fixtures and Jigs

Different printing technologies offer unique strengths for functional tooling. Boona Prototypes supports a range of processes, making it possible to match the method to the application.

| Technology | Accuracy | Build Volume | Best for Fixtures & Jigs |

|---|---|---|---|

| FDM (Fused Deposition Modeling) | ±0.3 mm | Up to 1000 × 1000 × 1000 mm | Large, low-cost fixtures; quick prototypes |

| SLA (Stereolithography) | ±0.1 mm | 800 × 800 × 550 mm | High-detail, ergonomic jigs requiring fine accuracy |

| SLS (Selective Laser Sintering) | ±0.2 mm | 700 × 380 × 580 mm | Durable nylon parts, lightweight custom fixtures |

| MJF (Multi Jet Fusion) | ±0.2 mm | 380 × 284 × 380 mm | Strong plastic fixtures, repeatable production |

| DMLS (Direct Metal Laser Sintering) | ±0.1–0.2 mm | 250 × 250 × 325 mm | Metal jigs for heavy-duty, high-temperature applications |

(Source: Boona Prototypes 3D Printing Service)

III. Advantages of 3D Printing Fixtures and Jigs

-

Rapid Turnaround – Parts can be delivered in 2–5 days depending on complexity.

-

Cost Savings – No tooling costs; economical for small-batch or one-off fixtures.

-

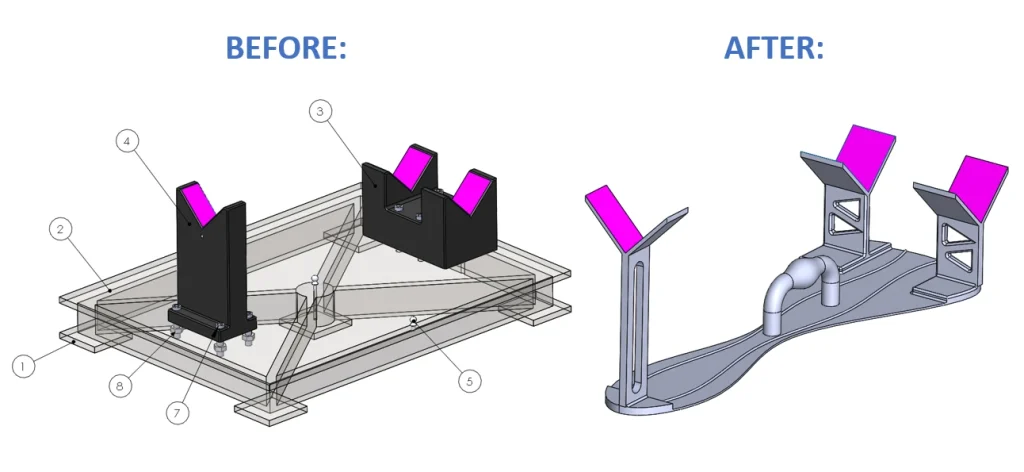

Complex Geometry – Hollow structures, integrated channels, and lightweight lattice designs.

-

Material Flexibility – Options include plastics (ABS, Nylon, Resin) and metals (Aluminum, Stainless Steel).

-

Customization – Ergonomic handles, tailored guides, and operator-friendly adjustments.

-

Reduced Waste – Additive manufacturing uses material efficiently compared to CNC or milling.

IV. Material Options for Fixtures and Jigs

Material selection is essential for balancing strength, weight, and durability.

| Material | Process | Properties | Applications |

|---|---|---|---|

| ABS / ASA | FDM | Tough, impact-resistant | General-purpose fixtures |

| Resin | SLA | High accuracy, smooth finish | Precision jigs, ergonomic parts |

| Nylon PA12 | SLS / MJF | Durable, lightweight, chemical-resistant | Assembly fixtures, clamps |

| Aluminum | DMLS | Strong, lightweight metal | Heat-resistant jigs, production tooling |

| Stainless Steel | DMLS | High strength, wear-resistant | Heavy-duty jigs, industrial fixtures |

(For full specifications, see Boona 3D Printing Materials).

V. Design Best Practices for 3D Printed Jigs and Fixtures

-

Define functional requirements (load, precision, environment).

-

Select the appropriate 3D printing technology for accuracy and durability.

-

Optimize for additive manufacturing: lightweight structures, reduced supports, modular components.

-

Plan for tolerance adjustments: e.g. ±0.1–0.3 mm depending on process.

-

Use post-processing (sanding, inserts, coatings) for long-term durability.

VI. Challenges to Consider

-

Material performance: plastics may deform under high loads or heat.

-

Size limitations: maximum build volumes depend on the printer.

-

Surface finish: some methods require post-processing for smoothness.

-

Cost trade-offs: metal printing is more expensive but provides superior durability.

VII. Future of 3D Printing in Fixtures and Jigs

-

Multi-material printing for combining rigid and flexible parts.

-

Embedded sensors in fixtures for smart manufacturing.

-

Generative design and topology optimization to reduce weight while increasing strength.

-

Faster industrial printers with larger build volumes for production tooling.

Conclusion

3D printing has become a game-changer in the creation of custom fixtures and jigs. Its ability to produce strong, lightweight, and tailored tools in days makes it invaluable for industries like automotive, aerospace, electronics, and medical devices.

By leveraging Boona Prototypes 3D printing services, manufacturers can rapidly develop functional fixtures and jigs that reduce cost, increase efficiency, and accelerate product development cycles.

FAQs

1. What are the main benefits of 3D printing custom fixtures and jigs?

3D printing offers faster turnaround times, lower costs for small batches, the ability to create complex geometries, and a wide range of material options. It also allows manufacturers to quickly iterate designs without expensive tooling.

2. How strong are 3D printed fixtures and jigs?

The strength depends on the printing process and materials used. For example, nylon (PA12) from SLS or MJF provides durable, lightweight fixtures, while metal 3D printing (DMLS/SLM) produces high-strength jigs suitable for industrial use.

3. What materials can be used to 3D print fixtures and jigs?

Common materials include plastics like ABS, ASA, resins, and nylon, as well as metals like aluminum and stainless steel. The right choice depends on load requirements, temperature resistance, and chemical exposure.

4. Can 3D printed jigs and fixtures replace traditional machined tools?

In many cases, yes. For lightweight, custom, or ergonomic tools, 3D printing can fully replace machining. For heavy-duty or high-temperature applications, metal 3D printing is often the preferred solution. However, some large or high-precision parts may still require CNC machining.

5. What is the accuracy of 3D printed fixtures and jigs?

Accuracy ranges from ±0.1 mm with SLA and DMLS to ±0.3 mm with FDM. Choosing the right technology depends on the tolerances required for your project.

6. How fast can I get a 3D printed fixture or jig?

With services like Boona Prototypes, lead times are typically 2–5 days depending on the complexity, size, and material. This makes 3D printing ideal for rapid prototyping and production support.

7. Are there size limitations for 3D printed jigs and fixtures?

Yes, maximum build sizes vary by process — for example, up to 1000 × 1000 × 1000 mm for FDM, but smaller for metal printing (around 250 × 250 × 325 mm). Larger fixtures may be printed in multiple sections and assembled.

8. Do 3D printed fixtures require post-processing?

Often yes. Depending on the process, post-processing may include support removal, sanding, machining inserts, or surface finishing. This ensures proper tolerances and durability for industrial use.

9. Which industries benefit most from 3D printed fixtures and jigs?

Automotive, aerospace, medical device, and electronics industries commonly use 3D printed tooling. The customization and rapid turnaround are especially valuable in low-volume production and prototyping environments.

10. How cost-effective is 3D printing compared to traditional methods?

For low-volume or custom parts, 3D printing is usually more economical because it eliminates tooling costs. For very large or mass-produced fixtures, traditional machining may still be more cost-effective.