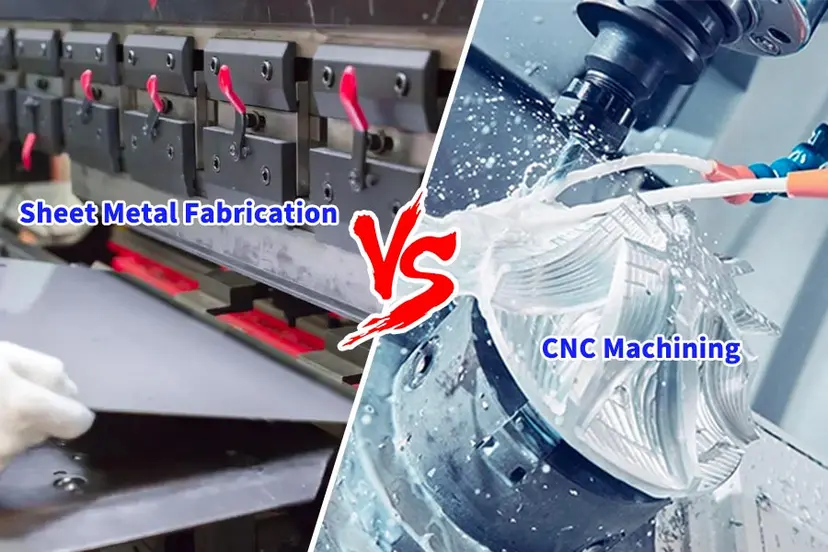

Sheet Metal Fabrication vs. Machining: Key Differences

Manufacturers often choose between sheet metal fabrication and CNC machining to produce custom parts. Both processes are essential for modern prototyping and production, but they differ greatly in methods, materials, tolerances, and cost. Understanding these differences helps engineers choose the right process for each application — and at Boona Prototypes, both services are available for rapid, high-quality manufacturing.

I. Process Overview

| Process | Description | Common Equipment | Applications |

|---|---|---|---|

| Sheet Metal Fabrication | Forming flat metal sheets into parts through cutting, bending, and welding | Laser cutters, brake presses, rollers | Enclosures, brackets, housings |

| CNC Machining | Removing material from a solid block to create complex shapes | CNC mills, lathes, 5-axis machines | Structural parts, molds, precision components |

Boona offers both CNC Machining Services and Sheet Metal Fabrication under one roof — enabling engineers to choose the most efficient route from prototype to production.

II. Materials and Capabilities

| Category | Typical Materials | Thickness/Size Range | Example Parts |

|---|---|---|---|

| Sheet Metal | Aluminum, Stainless Steel, Cold-rolled Steel, Copper | 0.5–10 mm | Brackets, Panels, Covers |

| CNC Machining | Aluminum 6061/7075, Stainless Steel 304/316, Brass, POM, ABS | Up to 300×300×150 mm (customizable) | Gears, Fixtures, Precision Housings |

👉 Explore Boona’s full list of Machinable Metals and Plastics.

III. Design and Geometry Differences

-

Sheet Metal: Best suited for parts with flat surfaces, bends, and simple 2D profiles.

-

Machining: Capable of creating 3D contours, threads, pockets, and holes with tight tolerances up to ±0.01 mm (see CNC Precision Machining).

| Factor | Sheet Metal | Machining |

|---|---|---|

| Geometry | Flat & bent shapes | Complex 3D forms |

| Minimum radius | Depends on thickness | Not limited |

| Internal cavities | Not possible | Easily machined |

IV. Surface Finish and Tolerances

Both methods support a range of surface treatments for appearance and performance. Boona offers Surface Finishing Options such as anodizing, powder coating, and polishing.

| Method | Typical Tolerance | Common Finishes |

|---|---|---|

| Sheet Metal | ±0.2 mm | Paint, Powder Coat, Zinc Plating |

| CNC Machining | ±0.01 mm | Anodize, Bead Blast, Polishing |

V. Cost and Lead Time Comparison

| Aspect | Sheet Metal Fabrication | CNC Machining |

|---|---|---|

| Setup Cost | Low for small runs | Higher setup for complex geometry |

| Material Waste | Minimal | More waste from material removal |

| Lead Time | 2–5 days | 3–7 days (depends on complexity) |

| Ideal Volume | Medium to high | Low to medium (prototypes, precision) |

At Boona Prototypes, you can also combine both processes for low-volume production — saving cost while maintaining quality.

VI. Applications

| Industry | Sheet Metal Use | Machining Use |

|---|---|---|

| Automotive | Body panels, brackets | Engine components, housings |

| Electronics | Enclosures, heat sinks | Connectors, precision mounts |

| Aerospace | Lightweight panels | Turbine prototypes, fixtures |

| Medical | Cabinets, holders | Surgical tools, precision molds |

VII. Choosing Between the Two

Choose Sheet Metal Fabrication when:

-

You need lightweight, simple geometries.

-

The design involves bending or welding.

-

Cost-efficiency and speed are priorities.

Choose CNC Machining when:

-

Precision and dimensional accuracy are critical.

-

The part requires 3D geometry or complex surfaces.

-

Strength and surface finish are important.

For the best results, consult Boona Engineering Support Team — they can provide design feedback and manufacturability analysis before production.

IX. Example Comparison

| Specification | Sheet Metal Enclosure | CNC Machined Housing |

|---|---|---|

| Material | 1.5 mm Aluminum | Aluminum 6061 Block |

| Process | Laser Cut + Bend + Weld | CNC Milled + Drilled |

| Finish | Powder Coated | Anodized |

| Tolerance | ±0.2 mm | ±0.01 mm |

| Unit Cost | $20 | $65 |

| Lead Time | 4 days | 6 days |

Conclusion

Both sheet metal fabrication and CNC machining play vital roles in product development. Sheet metal is ideal for simple, lightweight parts, while machining excels in precision, complexity, and durability.

At Boona Prototypes, you can access both processes — along with 3D printing, injection molding, and finishing services — under one platform. Their ISO 9001-certified quality control ensures every part meets strict tolerance and appearance standards.

Whether you need rapid prototypes or low-volume production, Boona helps you bring your design to life — quickly, accurately, and cost-effectively.

FAQs

1. What is the main difference between sheet metal fabrication and machining?

The key difference lies in the manufacturing method. Sheet metal fabrication forms and joins thin sheets of metal into parts, while CNC machining removes material from a solid block to achieve the final shape.

👉 Learn more about both services at Boona Prototypes.

2. Which process offers better precision—machining or sheet metal fabrication?

CNC machining offers higher precision with tolerances as tight as ±0.01 mm, ideal for components requiring detailed 3D geometry. Sheet metal fabrication typically achieves ±0.2 mm, suitable for larger enclosures or brackets.

3. What materials are commonly used in sheet metal fabrication and machining?

Sheet metal parts usually use aluminum, stainless steel, and cold-rolled steel, while machined parts may include brass, copper, plastics (POM, ABS), and various aluminum alloys.

You can check Boona’s full Material List for detailed specifications.

4. When should I choose sheet metal fabrication over CNC machining?

Choose sheet metal fabrication if your part has:

-

Simple or flat geometries

-

Lightweight requirements

-

Need for fast and economical production

For example, electronic housings and mounting brackets are typically fabricated from sheet metal.

5. When is CNC machining the better option?

Select CNC machining for:

-

Complex 3D shapes or internal cavities

-

Tight tolerances and smooth surface finishes

-

High-strength or precision components

Examples include engine housings, precision fixtures, and custom gears.

6. Can sheet metal and machining be combined for one part?

Yes. Many products use hybrid manufacturing, where the main body is fabricated from sheet metal and specific components (e.g., mounts or inserts) are CNC machined.

Boona specializes in low-volume production combining multiple methods — see Low Volume Manufacturing.

7. What is the lead time for each process?

Typical lead times:

-

Sheet metal fabrication: 2–5 working days

-

CNC machining: 3–7 working days

Actual time depends on design complexity, quantity, and finishing options. Boona offers rapid prototyping to speed up turnaround. (Rapid Prototyping Services)

8. Which process is more cost-effective for prototypes?

For simple parts, sheet metal fabrication is usually more cost-effective due to minimal material waste and faster setup. For complex precision parts, CNC machining offers better accuracy despite higher cost per unit.

9. What types of finishes are available for both methods?

Common finishes include anodizing, powder coating, bead blasting, and plating. Both processes support aesthetic and corrosion-resistant coatings. Explore Boona’s full range of Surface Finishing Options.

10. Does Boona Prototypes provide design assistance?

Yes. The Boona Prototypes engineering team offers DFM (Design for Manufacturability) support, helping you select the optimal process, material, and finish for your design.