The Critical Role of Material Hardness in CNC Machining Strategy

I. Introduction

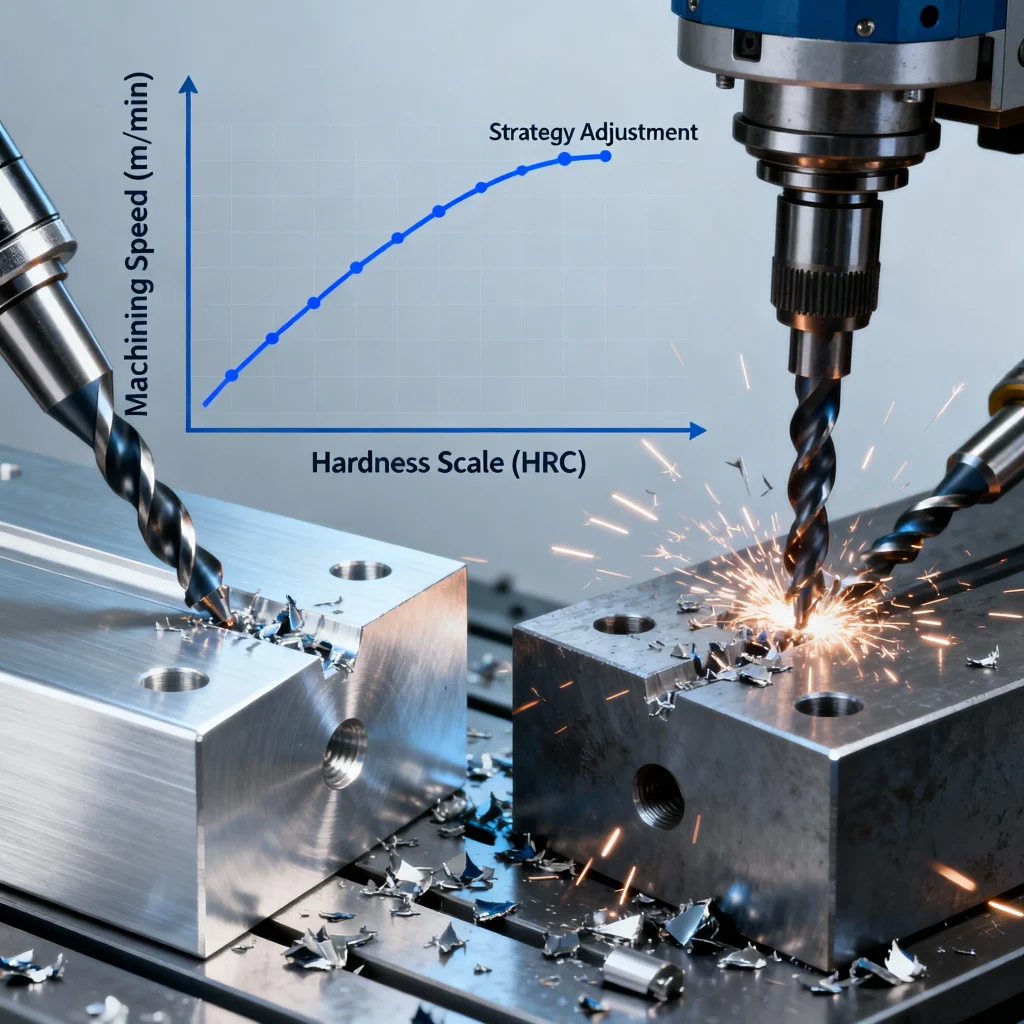

Precision CNC Machining—encompassing processes like CNC Milling and Turning—is the bedrock of modern manufacturing, delivering the rapid prototypes and production parts essential for virtually every industry. A fundamental challenge in this field lies in adapting the machining process to the specific properties of the material being cut. Among these properties, material hardness is paramount.

Material hardness, defined as the resistance to permanent shape change (e.g., indentation or abrasion), is the single greatest predictor of machining behavior. It dictates the forces required to cut the material, the amount of heat generated, and, critically, the lifespan of the cutting tool. The entire machining strategy—the choice of tools, the selected speeds and feeds, and the use of coolant—must be meticulously tailored to this property to ensure precision and efficiency. At companies specializing in on-demand, custom parts like BOONA Prototypes, this strategic adaptation is essential for meeting strict tolerance standards and delivering fast turnarounds.

II. Material Hardness and Its Mechanical Correlates

Hardness is not an isolated property; it correlates strongly with other mechanical characteristics that directly influence machinability:

- Tensile and Yield Strength: Increased hardness typically implies higher strength, which translates to greater cutting forces and higher power requirements from the machine spindle.

- Abrasion Resistance: A harder material is inherently more abrasive, leading to accelerated wear mechanisms on the cutting edge.

- Work Hardening: Materials like Austenitic Stainless Steel (e.g., 304, 316) exhibit a propensity to harden rapidly when subjected to plastic deformation. This requires specialized strategies, as highlighted in BOONA resources on Advanced Techniques for Machining Stainless Steel Alloys.

III. Direct Impacts on Machining Strategy: Parameters and Tooling

The material’s hardness directly informs the selection of cutting tools and the setting of critical process parameters:

A. Cutting Tool Material and Coating Selection

To combat the high temperatures and severe abrasion encountered when machining hard materials (typically $>45$ HRC), tool engineers must move up the material hierarchy:

| Workpiece Hardness | Recommended Tool Material | Primary Wear Mechanism | Coating Strategy (Example) |

| Soft ($\text{HB}<150$) | High-Speed Steel (HSS), Uncoated Carbide | Adhesion, Built-Up Edge (BUE) | None/Smooth Surface |

| Medium ($\text{HB}$ 150-300) | Coated Carbide (Cermet) | Diffusion, Crater Wear | TiN, TiAlN |

| Hard ($\text{HRC}$ 45-65) | Cermet, Ceramic, Coated Carbide | Abrasive Wear, Thermal Shock | AlTiN, $\text{Al}_2\text{O}_3$ |

| Very Hard ($\text{HRC}>65$) | Polycrystalline Cubic Boron Nitride (PCBN) | High-Temperature Abrasive Wear | CVD (Chemical Vapor Deposition) |

B. Optimization of Machining Parameters

The primary cutting parameters—Cutting Speed ($V_c$), Feed Rate ($f$), and Depth of Cut ($a_p$)—must be adjusted inversely to the material’s hardness.

| Parameter | Impact of Increased Workpiece Hardness | Strategic Adjustment |

| Cutting Speed ($V_c$) | Increases thermal load on tool tip. | Decrease $V_c$ to manage heat and slow diffusion wear. |

| Feed Rate ($f$) | Increases cutting force; can prevent work hardening. | Maintain or Slightly Increase $f$ to ensure the tool always cuts beneath the prior cut’s hardened layer. |

| Depth of Cut ($a_p$) | Dramatically increases required spindle power and risk of vibration. | Reduce $a_p$ and increase radial engagement ($a_e$) (e.g., in Trochoidal Milling) for better thermal distribution. |

Example Machining Data (Illustrative):

| Material Grade | Hardness (BHN) | Suggested Vc (m/min) (Carbide Tool) | Suggested fz (mm/tooth) (Milling) |

| Aluminum 6061 | 95 | 200 – 350 | 0.08 – 0.15 |

| Mild Steel 1018 | 130 | 150 – 250 | 0.06 – 0.12 |

| Stainless Steel 304 | 180 | 80 – 150 | 0.05 – 0.10 |

| Hardened Tool Steel H13 | 50 HRC (~500 BHN) | 30 – 60 | 0.01 – 0.04 |

Note: These values are general guidelines. Optimal parameters are highly dependent on machine rigidity, tool geometry, and coolant application.

IV. Quality Control and Verification

The final product’s quality is intrinsically linked to the hardness-driven machining strategy. Machining extremely hard materials can introduce high residual stresses and poor surface finishes if the strategy is incorrect.

- Hardness Inspection: Verifying the post-machining hardness is a crucial quality step. As part of its rigorous process, BOONA provides Hardness Inspection Reports to ensure that the finished part’s properties meet the design specifications, guaranteeing integrity despite the aggressive machining required for tough alloys.

- Surface Integrity: A poor strategy (e.g., low feed rate on stainless steel) causes rubbing, leading to severe work hardening and reduced fatigue life of the final component. Precision machining requires a strategy that cuts cleanly beneath any hardened layer from previous passes.

Conclusion

The hardness of a workpiece material is the ultimate determinant of a successful CNC machining operation. From selecting a wear-resistant PCBN insert for hardened steel to implementing high-feed, moderate-speed trochoidal tool paths for tough titanium, every decision in the machining process hinges on this core mechanical property. By employing a disciplined, data-driven approach to tool and parameter selection, manufacturers can efficiently overcome the unique challenges presented by hard materials, ensuring the rapid and high-precision delivery of prototypes and production parts.

FAQs

1. What is the fundamental relationship between material hardness and machining?

The fundamental relationship is inverse: as material hardness increases, its machinability generally decreases. Harder materials require greater cutting forces, generate more heat, and cause significantly faster tool wear due to increased abrasion and temperature. This necessitates a more conservative and specialized machining strategy.

2. How is material hardness typically measured in a manufacturing context?

Hardness is primarily measured using indentation tests. The most common scales relevant to CNC machining materials are:

- Brinell (HB): Often used for softer materials like Aluminum and annealed steels.

- Rockwell (HRC/HRB): Very common for steels, with the C-scale ($\text{HRC}$) used for hard metals and the B-scale ($\text{HRB}$) for softer ones.

- Vickers (HV): Used for a wide range of materials, often for thin cases or micro-hardness testing.

3. Does higher hardness always mean poorer machinability?

Not always. While high hardness increases abrasive wear, a tough and gummy (ductile) material—like certain pure coppers or soft aluminum grades—can also have poor machinability because it causes chip-control issues and results in a Built-Up Edge (BUE) on the tool, leading to a poor surface finish. The ideal material for easy machining is often moderately hard but brittle (e.g., free-machining brass).

4. How does hardness affect the choice of cutting tool material?

Increased workpiece hardness demands increased hot hardness and wear resistance from the cutting tool.

- For $\text{HRC} \le 40$ (medium hardness), Tungsten Carbide tools are standard.

- For $\text{HRC}$ $45$ to $65$ (hardened steel), specialized materials like Ceramics or Polycrystalline Cubic Boron Nitride (PCBN) are necessary. PCBN is essential for “hard turning” where the hardness is too great for conventional carbide.

5. Why must cutting speeds ($V_c$) generally decrease when machining harder materials?

Cutting speed is the primary driver of heat generation. When machining hard materials, the mechanical energy converted to heat is high. Reducing $V_c$ helps manage this thermal load, preventing the tool’s cutting edge from softening (losing its hot hardness) and delaying the onset of rapid diffusion wear (where tool and workpiece material chemically react).

6. What is the biggest challenge when machining work-hardening materials like Stainless Steel, and how is it addressed?

The biggest challenge is work hardening—the material becomes harder as it’s cut. This creates an extremely hard surface layer for the subsequent pass. It is addressed by:

- Using sharp tools with positive rake angles to slice instead of push.

- Maintaining a sufficiently high feed rate ($f$) and depth of cut ($a_p$) to ensure the tool tip cuts beneath the previously work-hardened layer.

- Maintaining constant cutting engagement to avoid “dwelling” or “rubbing,” which causes the hardening.

7. What role does coolant play when machining hard materials?

For hard materials, coolant is critical for two reasons:

- Thermal Management: It carries heat away from the cutting zone, preserving the tool’s hot hardness.

- Chip Evacuation: High-pressure coolant ($\text{HPC}$) can break difficult chips and force them out of the cutting zone, preventing re-cutting and thermal spikes.

8. How does a poor machining strategy for hard materials affect the final part quality?

A poor strategy (e.g., using dull tools or low feeds) leads to:

- Accelerated Tool Wear: Requires frequent tool changes and increases cost.

- Poor Surface Finish: Due to chipping, vibration (chatter), or BUE.

- Reduced Component Life: Due to high residual stress or undesirable work hardening on the surface layer, which can lead to premature failure in service.

9. What quality control step is essential after machining a hard material?

The most essential step is verifying the resulting material properties with a Hardness Inspection Report (as emphasized by the quality control at BOONA Prototypes). This ensures that the machining process did not induce undesirable thermal effects or excessive work hardening that could compromise the material’s intended function or strength.