Welding is one of the most essential processes in modern manufacturing, construction, and metal fabrication. From car frames to aerospace components, welds hold the world together—literally. Among the many welding techniques available, MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding stand out as the most popular and versatile methods.

Each process has unique advantages, costs, and technical parameters that make it suitable for specific materials and applications. In this guide, we’ll compare MIG vs. TIG welding in detail, including process data, performance parameters, and practical examples to help you choose the right joining method for your project.

What Is MIG Welding?

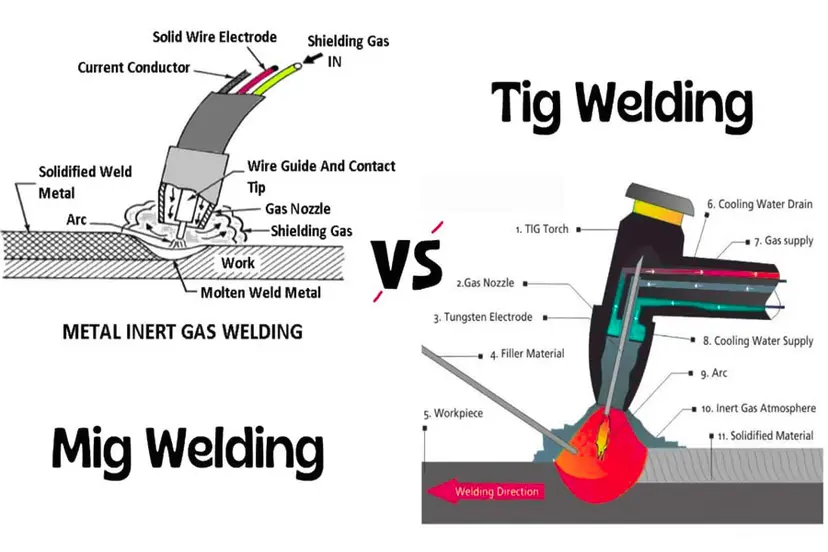

MIG welding, also known as Gas Metal Arc Welding (GMAW), uses a continuously fed consumable wire electrode and an inert shielding gas (commonly Argon or Argon/CO₂ mix) to create a weld pool.

It’s a semi-automatic process that allows operators to maintain consistent welds with minimal interruptions. MIG welding is widely used in automotive manufacturing, general fabrication, and construction due to its high productivity.

Key Advantages

-

High welding speed and deposition rate

-

Easy to learn and operate — ideal for beginners

-

Suitable for thicker materials and mass production

-

Compatible with steel, aluminum, and stainless steel

Limitations

-

More spatter and cleanup required

-

Limited precision for thin or delicate materials

-

Requires shielding gas (less effective outdoors)

Typical MIG Parameters

| Parameter | Mild Steel | Stainless Steel | Aluminum |

|---|---|---|---|

| Shielding Gas | 75% Ar / 25% CO₂ | 98% Ar / 2% O₂ | 100% Argon |

| Wire Diameter | 0.8 – 1.2 mm | 0.8 – 1.0 mm | 1.0 – 1.6 mm |

| Voltage | 18 – 30 V | 18 – 28 V | 20 – 24 V |

| Amperage | 60 – 300 A | 50 – 250 A | 100 – 250 A |

| Welding Speed | 200 – 500 mm/min | 150 – 350 mm/min | 250 – 400 mm/min |

What Is TIG Welding?

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), uses a non-consumable tungsten electrode to produce a clean, precise weld. A separate filler rod can be used when additional material is needed. The weld area is protected by an inert gas (typically 100% Argon), ensuring oxidation-free results.

This process is slower but provides exceptional control and high-quality welds, making it ideal for applications requiring accuracy, such as aerospace, food processing equipment, and artistic metalwork.

1. Key Advantages

-

Extremely clean and precise welds

-

Ideal for thin materials and non-ferrous metals (aluminum, titanium)

-

No spatter or smoke

-

Excellent aesthetic finish

2. Limitations

-

Slower welding process

-

Requires advanced skill and steady hand control

-

More expensive equipment and higher gas usage

3. Typical TIG Parameters

| Parameter | Mild Steel | Stainless Steel | Aluminum |

|---|---|---|---|

| Shielding Gas | 100% Argon | 100% Argon | 100% Argon |

| Electrode Type | 2% Thoriated (Red) | 2% Ceriated (Grey) | Pure Tungsten (Green) |

| Current Type | DCEN | DCEN | AC |

| Amperage | 30 – 150 A | 30 – 200 A | 50 – 250 A |

| Welding Speed | 80 – 250 mm/min | 70 – 200 mm/min | 100 – 250 mm/min |

Key Differences Between MIG and TIG Welding

| Category | MIG Welding | TIG Welding |

|---|---|---|

| Full Name | Gas Metal Arc Welding (GMAW) | Gas Tungsten Arc Welding (GTAW) |

| Electrode Type | Consumable wire electrode | Non-consumable tungsten electrode |

| Shielding Gas | Argon/CO₂ mixture | 100% Argon or Argon-Helium mix |

| Speed | Faster (up to 500 mm/min) | Slower (typically 150–250 mm/min) |

| Skill Level | Easier to learn | Requires high skill and coordination |

| Precision | Moderate | Very high |

| Weld Appearance | More spatter, less aesthetic | Smooth, clean, professional finish |

| Suitable Material Thickness | 1.5 – 25 mm | 0.5 – 6 mm |

| Typical Use | Automotive, construction, repair | Aerospace, stainless steel, artistic fabrication |

| Equipment Cost | Lower | Higher |

| Productivity | High | Moderate to low |

Factors to Consider When Choosing

a. Material Type and Thickness

-

MIG welding is better for thick carbon steel or structural metals.

-

TIG welding excels at thin sheets or non-ferrous metals like aluminum, copper, or titanium.

b. Weld Quality and Aesthetics

If appearance and precision are critical—such as in visible joints or high-spec components—TIG provides superior control and finish.

c. Production Speed

MIG welding offers faster travel speeds and higher deposition rates, making it ideal for high-volume manufacturing.

d. Skill Level

TIG welding demands more training and steady hand coordination. MIG welding is beginner-friendly and widely used in vocational training programs.

e. Cost

MIG systems are generally more economical, with lower operating and maintenance costs. TIG systems, though more expensive, offer higher quality results for critical projects.

Applications

| Industry | Preferred Method | Typical Materials |

|---|---|---|

| Automotive | MIG | Mild steel, aluminum |

| Aerospace | TIG | Stainless steel, titanium |

| Construction | MIG | Structural steel |

| Food & Beverage Equipment | TIG | Stainless steel |

| Art & Sculpture | TIG | Brass, bronze, aluminum |

| Agricultural Equipment | MIG | Carbon steel |

Pros and Cons Summary

MIG Welding

Pros:

✔ Fast and efficient

✔ Easier to learn

✔ High productivity for large-scale projects

✔ Lower equipment cost

Cons:

✘ More spatter and cleanup

✘ Limited precision on thin metals

✘ Requires shielding gas, limiting outdoor use

TIG Welding

Pros:

✔ Clean, precise welds

✔ No spatter, superior aesthetics

✔ Excellent for thin or exotic metals

✔ Better mechanical properties

Cons:

✘ Slower process

✘ Higher skill requirement

✘ More expensive setup

Which Welding Method Is Right for You?

Choosing between MIG and TIG depends on your project priorities:

| If your priority is… | Choose… |

|---|---|

| Speed and productivity | MIG |

| Precision and quality | TIG |

| Thick structural metals | MIG |

| Thin or delicate metals | TIG |

| Budget efficiency | MIG |

| Aesthetic weld finish | TIG |

In many fabrication workshops, both methods are used in tandem: MIG for rapid assembly, and TIG for precision finishing.

Conclusion

Both MIG and TIG welding are indispensable technologies in metal fabrication.

-

MIG welding offers speed, efficiency, and affordability for large projects.

-

TIG welding delivers precision, aesthetics, and superior metallurgical quality for specialized applications.

The best choice depends on your material, budget, skill level, and quality requirements. For maximum flexibility, many modern fabrication shops integrate both processes—achieving the perfect balance between productivity and craftsmanship.

FAQs

Which welding method is stronger — MIG or TIG?

Both methods can create strong welds when performed correctly. However, TIG welding generally produces cleaner, more precise, and structurally stronger joints, especially for thin materials and critical applications.

What are the main differences between MIG and TIG welding?

MIG welding uses a consumable wire electrode and is faster and easier to learn.

TIG welding uses a non-consumable tungsten electrode and offers better precision and aesthetics but requires more skill.

Which process is better for beginners — MIG or TIG?

MIG welding is ideal for beginners because it’s easier to control, more forgiving of mistakes, and faster to master compared to TIG welding.

Which welding method gives a cleaner appearance?

TIG welding produces neater and more aesthetic welds with little to no spatter, making it the preferred choice for visible or decorative joints.

Can MIG weld aluminum?

Yes, MIG can weld aluminum using 100% Argon shielding gas and a spool gun or push-pull gun setup. However, TIG welding often produces cleaner results on aluminum due to better control of heat input.

Can TIG weld thick materials?

TIG can weld thick metals, but it’s less efficient for heavy sections due to slower deposition rates. MIG is more practical for thicker steel plates or structural components.

Which welding process is faster?

MIG welding is significantly faster than TIG, often 2–3 times quicker, making it ideal for mass production and industrial applications.

Is TIG welding more expensive than MIG?

Yes. TIG welding involves higher equipment cost, gas consumption, and operator skill, making it more expensive overall. MIG welding is generally more economical for large-scale projects.

What types of materials can be welded with MIG and TIG?

Both can weld steel, stainless steel, and aluminum. TIG is also suitable for magnesium, copper, bronze, and titanium, while MIG is more commonly used for carbon steel and aluminum.

Which process is best for thin materials?

TIG welding is superior for thin materials (below 2 mm) because it allows precise control of heat and filler material, minimizing burn-through and distortion.

What kind of shielding gases are used in MIG and TIG welding?

-

MIG welding: Argon/CO₂ mix for steel, pure Argon for aluminum.

-

TIG welding: 100% Argon, or Argon/Helium blends for deeper penetration.

Which method is more portable for field use?

MIG welders are generally more portable and faster to set up, but flux-cored MIG (FCAW) is better for outdoor conditions since it doesn’t require external shielding gas. TIG is more suited to indoor, controlled environments.

Can I use both MIG and TIG welders in the same workshop?

Absolutely. Many fabrication shops use MIG for fast, large welds and TIG for fine, high-quality finishing on the same projects.

What kind of maintenance do MIG and TIG machines require?

-

MIG: Regular wire feed system cleaning, tip and liner replacement.

-

TIG: Electrode grinding, torch cleaning, and gas nozzle maintenance.

Proper maintenance ensures consistent weld quality and machine longevity.

Which welding process is better for stainless steel?

Both can weld stainless steel, but TIG welding is preferred for applications where weld appearance and corrosion resistance are critical (e.g., food-grade or medical components).