In today’s rapidly evolving manufacturing world, the ability to produce high-quality parts quickly and cost-effectively is essential—especially for startups, product developers, or engineers conducting market validation. Vacuum casting is a standout solution for low-volume production (10–200 units) that offers injection-molding-like quality without the high cost or long lead times of traditional tooling.

Whether you’re transitioning from prototype to pilot production or simply need durable functional parts fast, vacuum casting serves as the perfect bridge.

What is Vacuum Casting?

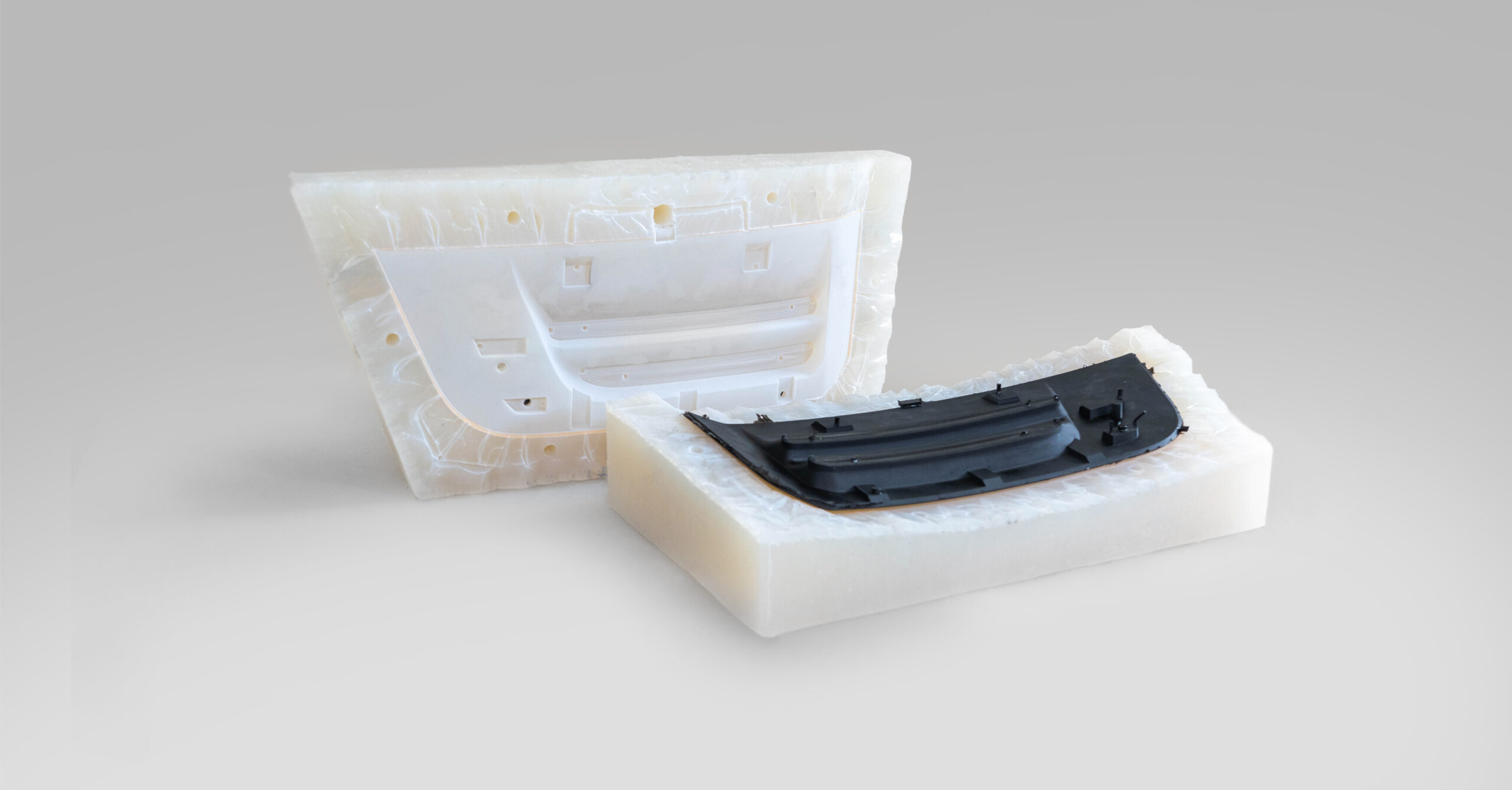

Vacuum casting is a polyurethane molding process that uses a 3D-printed or CNC-machined master pattern to create a silicone mold. Liquid resin is poured into the mold under vacuum to eliminate air bubbles—resulting in smooth, detailed, production-quality replicas.

Typical Production Volumes: 10–200 pcs per design

Lead Time: ~7–14 days depending on complexity

Best For: Engineering prototypes, concept validation, low-volume product launches

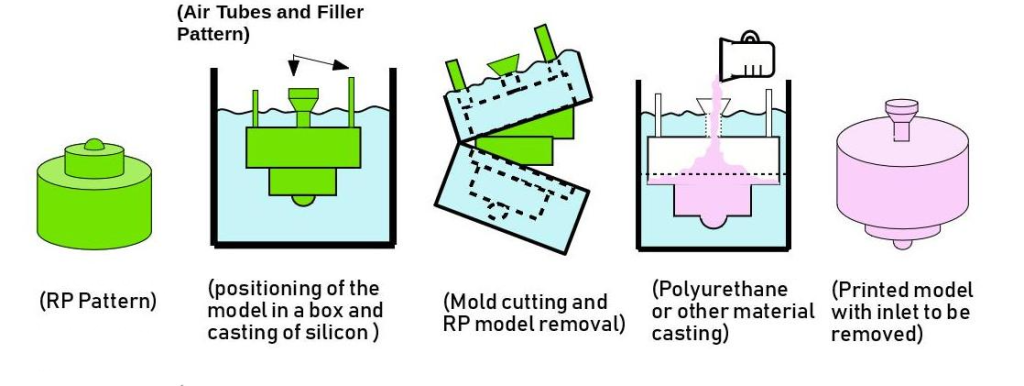

How the Vacuum Casting Process Works

| Step | Process | Notes |

|---|---|---|

| 1️⃣ | Master pattern creation (CNC/3D printing) | High surface accuracy required |

| 2️⃣ | Silicone mold fabrication | Mold cures 6–24 hours |

| 3️⃣ | Vacuum casting & resin filling | Removes trapped air for bubble-free parts |

| 4️⃣ | Curing (room temp or heat) | Depends on resin type |

| 5️⃣ | Demolding & trimming | Excellent replication of fine details |

| 6️⃣ | Surface finishing | Painting, texture, polishing optional |

Replication fidelity: Up to ±0.1–0.3 mm tolerance

Key Advantages of Vacuum Casting

| Benefit | Details |

|---|---|

| ✅ Low cost | No steel/aluminum tooling needed |

| ⚡ Fast turnaround | 7–14 days vs 4–12 weeks for injection molding |

| 🎯 High-quality finish | Smooth surfaces, near-production accuracy |

| 🧪 Functional material behavior | Engineering-grade polyurethane |

| 🎨 Aesthetic flexibility | Transparency, pigmentation, gloss, texture |

| 🔄 Multiple parts per mold | 15–25 casts per silicone mold |

📌 Ideal substitute for ABS, PP, PC, rubber-like, PMMA materials.

Vacuum Casting vs. Other Manufacturing Methods

| Feature / Process | Vacuum Casting | 3D Printing | Injection Molding |

|---|---|---|---|

| Best Volume | 10–200 units | 1–10 units | 1,000+ units |

| Lead Time | 7–14 days | 1–3 days | 4–12 weeks |

| Surface Finish | Smooth / paintable | Layer lines | Excellent |

| Tooling Cost | Low | None | Very high ($5,000–$80,000+) |

| Material Selection | Very wide | Limited variants | Very wide |

| Mechanical Strength | High | Medium | Highest |

✅ Vacuum casting is best for design validation before investing in metal tooling.

Material Options & Performance Data

Vacuum casting resins simulate real engineering plastics. Below is a typical parameter table:

| Material Type | Equivalent Plastic | Hardness (Shore) | Tensile Strength | Heat Resistance |

|---|---|---|---|---|

| ABS-like Resin | ABS | 75–80D | 45–55 MPa | 60–80°C |

| PP-like Resin | PP | 70–75D | 25–35 MPa | 60–80°C |

| PC-like Resin | PC | 80–85D | 60–70 MPa | 90–120°C |

| Rubber-like | TPU | 30A–90A | 5–10 MPa | 50–60°C |

| Transparent Resin | PMMA/PC | 80–85D | 45–55 MPa | 70–90°C |

📌 Custom colors, textures, and over-molding also available.

Quality Assurance & Tolerances

-

Dimensional tolerance: ±0.1–0.3 mm

-

Surface finish: Glossy, matte, or textured achievable

-

Inspection: CMM, 3D scanning, functional testing offered

-

Compliance (optional): ISO 9001 quality management available from many suppliers

Common Applications

| Industry | Typical Parts |

|---|---|

| Automotive | Knobs, lighting housings, dashboard components |

| Consumer Electronics | Enclosures, wearable accessories |

| Medical & Healthcare | Device prototypes, ergonomic handles |

| Industrial Equipment | Custom housings & connectors |

| Marketing & Product Launch | Pre-production samples |

🧲 Best when products require functional and visual validation before mass manufacturing.

Realistic Mold Life Expectancy

| Mold Type | Expected Output |

|---|---|

| Small, simple parts | 20–25 casts |

| Medium complexity | 15–20 casts |

| Large / intricate geometry | 10–15 casts |

📌 Multiple molds can be created in parallel to increase output volume.

Conclusion

Vacuum casting is the best solution when you need:

✅ Production-quality prototypes

✅ Fast delivery with highly realistic appearance

✅ Low-volume manufacturing without expensive tooling

By offering the appearance, precision, and strength of molded parts at a fraction of the cost and timeline, vacuum casting continues to lead the way for design verification, early marketing, and pilot manufacturing.

FAQs

What quantities are ideal for vacuum casting?

Typically 10–200 units per design. It’s perfect for low-volume runs, engineering verification, and pilot production before investing in injection molding.

How long does vacuum casting take?

Lead times are usually 7–14 days, depending on part complexity, finishing, and number of molds required.

What is the maximum size of parts for vacuum casting?

Most manufacturers can produce parts up to 2000 mm in length. Larger parts may require split molds or segmented production.

What materials can be used in vacuum casting?

Polyurethane resins simulating engineered plastics like ABS, PP, PC, TPU, and PMMA. Options include clear, rubber-like, heat-resistant, and colored resins.

How accurate are vacuum-cast parts?

Vacuum-cast parts typically achieve ±0.1–0.3 mm tolerances, with high surface quality and fine detail replication.

Can vacuum cast parts be painted or surface finished?

Yes. Options include painting, polishing, silk printing, texturing, clear coating, and metal electroplating.

How many parts can be produced from one silicone mold?

A single mold can produce 15–25 copies, depending on part complexity, structure, and resin type.

Can inserts or multiple materials be incorporated?

Yes. Metal inserts, threaded studs, and over-molding with soft/hard material combinations are possible.

Are vacuum-cast parts strong enough for functional testing?

Absolutely! Many resins simulate real plastic properties, making them ideal for mechanical tests, assembly validation, and product demos.

How does vacuum casting compare to 3D printing?

Vacuum casting offers better surface finish, material performance, and repeatability, while 3D printing is faster and cheaper for 1–5 prototypes.

Is vacuum casting suitable for mass production?

No — mold life is limited. For 1,000+ pcs, injection molding becomes more cost-effective.

Can vacuum casting achieve transparency?

Yes. Transparent and optical-grade materials similar to PC/PMMA are available, though polishing may be required for fully clear vision parts.

What industries commonly use vacuum casting?

Automotive, consumer electronics, medical devices, industrial equipment, IoT products, and wearable technology.

Is vacuum casting environmentally friendly?

Silicone molds are not reusable long-term and resin materials are petrochemical-based. However, low scrap generation helps reduce waste.

How much does vacuum casting cost?

Pricing varies, but generally 60–80% cheaper tooling cost than injection molding. Small batches offer significant savings.