In today’s fast-paced product development environment, companies are under constant pressure to turn ideas into functional parts faster than ever. With modern tools and optimized workflows, it is possible to go from CAD design to functional part in just 3 days — a timeline that would have been unimaginable a decade ago.

This accelerated approach allows for rapid design validation, faster testing, and quicker time-to-market, giving companies a competitive edge in product innovation.

Step 1: Optimized CAD Design

The journey begins with parametric CAD modeling, which enables engineers to rapidly modify dimensions and features without recreating the entire design.

Key Strategies:

-

Feature-based modeling: Enables fast changes to core design elements.

-

Collaboration tools: Cloud-based CAD systems allow simultaneous review and editing.

-

Design for Manufacturability (DFM): Incorporating manufacturability rules reduces iteration time.

| Parameter | Recommendation |

|---|---|

| CAD Software | SolidWorks, Autodesk Fusion 360, Creo |

| Design Iteration Time | 1–3 hours for minor changes |

| Collaboration | Real-time cloud review for multi-engineer teams |

Step 2: Rapid Prototyping & Master Pattern Creation

Next, the CAD model is translated into a physical prototype or master pattern.

Methods:

-

3D Printing (SLA, SLS, FDM): Rapid layer-by-layer production, ideal for complex geometries.

-

CNC Machining: High-precision prototypes using metal or high-strength plastic for functional testing.

Material Selection for Functionality:

| Material | Typical Use | Strength | Lead Time |

|---|---|---|---|

| ABS-like resin | Functional prototypes | Medium | 12–24 hours |

| Nylon (SLS) | Mechanical testing | High | 24 hours |

| Aluminum (CNC) | Structural parts | Very high | 1–2 days |

Tip: SLA 3D printing often provides the fastest route for high-detail parts, while CNC is preferred for mechanically functional or load-bearing prototypes.

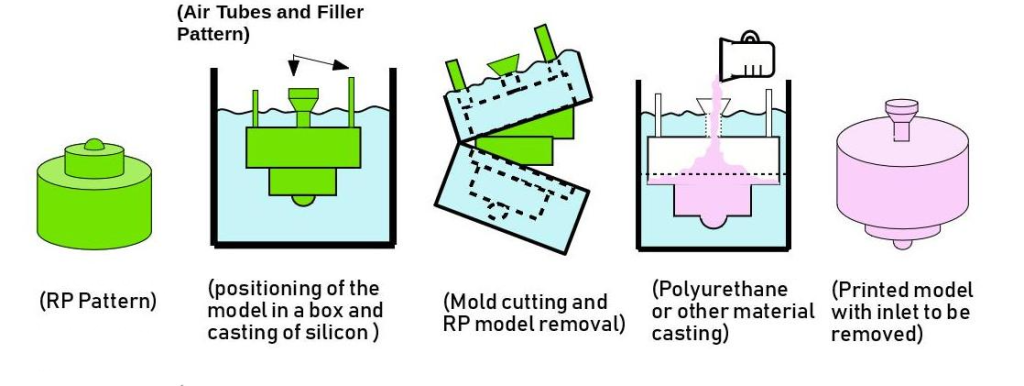

Step 3: Mold or Tool Preparation

Once a master pattern is ready, mold or tooling preparation enables low-volume production of functional parts.

-

Silicone molds for vacuum casting allow 10–25 copies per mold, ideal for small batches.

-

Quick-turn tooling is available for low-volume injection molding.

| Process | Lead Time | Typical Volume | Notes |

|---|---|---|---|

| Silicone mold | 6–12 hours | 10–25 pcs | Ideal for polyurethane casting |

| Quick-turn injection mold | 1 day | 50–100 pcs | Limited lifetime tooling |

Efficiency Tip: Parallelize mold fabrication with post-processing to stay on the 3-day schedule.

Step 4: Casting or Machining Functional Parts

Depending on material and function, parts are produced using:

-

Vacuum casting (for polyurethane resins, ABS-like materials)

-

Low-volume injection molding

-

CNC machining (metal or engineering plastics)

Parameters for Vacuum Casting:

| Parameter | Typical Range |

|---|---|

| Resin Type | ABS, PP, PC, TPU |

| Curing Time | 30–120 minutes |

| Mold Life | 15–25 parts |

| Tolerance | ±0.1–0.3 mm |

Parallel Processing: Casting multiple parts simultaneously or using multiple molds ensures the 3-day timeline is met.

Step 5: Post-Processing & Quality Checks

After parts are produced, trimming, sanding, polishing, and finishing are applied. Functional testing ensures that the part performs as intended.

Post-Processing Parameters:

| Step | Time | Notes |

|---|---|---|

| Trimming | 10–30 min/part | Remove flash from molds |

| Surface Finishing | 15–60 min/part | Polishing, painting, or coating |

| Functional Testing | 30 min/part | Dimensional and mechanical verification |

Tip: Concurrent post-processing (while other parts are casting) can save hours and keep the timeline on track.

Key Factors Enabling the 3-Day Timeline

-

Streamlined CAD-to-manufacturing workflow

-

Advanced rapid prototyping technologies (SLA, SLS, CNC)

-

Efficient communication among engineers, operators, and managers

-

Skilled teams with integrated software/hardware systems

The combination of technology and process optimization allows companies to go from concept to functional part in just 72 hours.

Benefits of Accelerated Timelines

| Benefit | Description |

|---|---|

| Faster Design Validation | Identify issues earlier, reducing costly late-stage redesigns |

| Reduced Time-to-Market | Accelerate product launches, gain competitive edge |

| Early Functional Testing | Test mechanical, thermal, or electrical performance sooner |

| Cost Efficiency | Reduce iteration cost by consolidating rapid production cycles |

Case Study Example

Scenario: A small consumer electronics company needed a functional enclosure for a new device.

| Step | Material / Technology | Lead Time |

|---|---|---|

| CAD design | Fusion 360 | 6 hours |

| Master pattern | SLA 3D print (ABS-like resin) | 12 hours |

| Silicone mold | RTV silicone | 8 hours |

| Casting | PU resin | 6 hours |

| Post-processing | Trimming + polishing | 4 hours |

| Total | — | ~36 hours |

Outcome: First fully functional part ready in less than 2 days, enabling immediate testing and feedback.

Conclusion

Accelerating the timeline from CAD to a functional part is now achievable through:

✅ Efficient CAD practices

✅ Rapid prototyping technologies

✅ Optimized mold preparation

✅ Parallel post-processing and functional testing

By compressing design-to-part workflows, companies can reduce iteration cycles, validate designs faster, and gain a substantial competitive advantage.

FAQs

What types of parts can be produced in 3 days?

Mostly small- to medium-sized prototypes made from polymers, resins, or lightweight metals. Functional mechanical parts, enclosures, and structural prototypes are typical.

Which technologies enable a 3-day turnaround?

-

SLA, SLS, FDM 3D printing for master patterns

-

CNC machining for metal or high-strength parts

-

Vacuum casting or low-volume injection molding for functional copies

Can high-strength metals like aluminum or titanium be produced in 3 days?

Yes, using CNC machining, but lead time depends on complexity. Polymers or resins are usually faster for low-volume production.

How many parts can be produced in this 3-day workflow?

-

Vacuum casting: ~10–25 parts per silicone mold

-

CNC machining: Depends on machine availability and batch size

-

3D printing: Can produce multiple patterns concurrently

Are functional tests included in the 3-day timeline?

Yes. Quick dimensional checks, fit tests, and basic mechanical tests can be integrated into the workflow without extending the timeline.

What factors might extend the 3-day schedule?

-

Highly complex geometries or very tight tolerances

-

Large parts requiring multiple setups

-

Specialized materials that require longer curing or post-processing

Can surface finishing be done within 3 days?

Yes, for basic trimming, polishing, sanding, or painting. More advanced finishes like anodizing or plating may require extra time.

How can companies ensure consistent 3-day delivery?

-

Optimize CAD models for manufacturability

-

Use parallel processing for mold preparation, casting, and post-processing

-

Plan materials and machine availability in advance

Is this process cost-effective for low-volume production?

Yes. It avoids expensive tooling while delivering functional, near-production quality parts rapidly.

Which industries benefit most from this workflow?

Consumer electronics, medical devices, automotive prototypes, industrial equipment, and startups requiring rapid iterations.