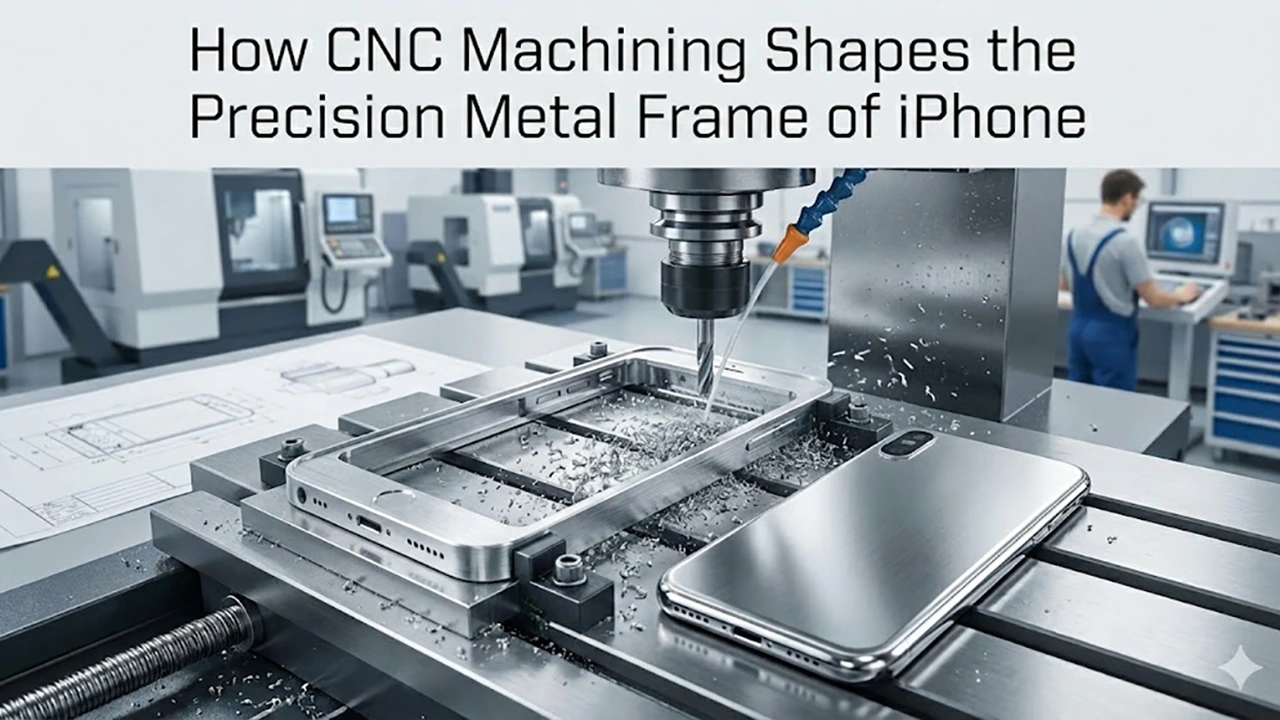

When you pick up an iPhone, specifically the Pro models, the first thing you notice is the temperature. It feels cold, dense, and rigid. This premium “jewelry-grade” feel is not an accident—it is the direct result of CNC (Computer Numerical Control) Machining.

Unlike many consumer electronics that rely on plastic injection molding or cheap metal stamping, Apple treats the iPhone chassis like an aerospace component. It is carved from a solid block of metal.

At Boona Prototypes, we apply these same high-precision CNC Machining Services to help our clients create enclosures that rival the quality of Silicon Valley’s giants. Whether you are developing a medical device or a premium consumer electronic, understanding the “Unibody” workflow is the key to achieving structural integrity and aesthetic perfection.

Here is how the world’s most iconic metal frame is manufactured.

The Foundation: Extrusion and the Titanium Shift

The process begins long before the milling tools start spinning. For the standard iPhone, Apple uses a custom 7000-series aluminum alloy, optimized for high strength and cosmetic anodizing.

With the iPhone 15/16 Pro, the material science shifted to Grade 5 Titanium. However, Titanium is poor at dissipating heat. The solution? A manufacturing marvel called Solid-State Diffusion.

-

Two distinct metals (an aluminum inner core and a titanium outer band) are bonded together under immense pressure and heat until their atoms intermingle.

-

This creates a hybrid block: The aluminum interior acts as a heatsink, while the titanium exterior provides the armor.

The Roughing Phase: Carving the Core

Once the blank enters the machine, high-speed 5-axis CNC mills begin “hogging out” the material. Roughly 80% to 90% of the original metal block is removed and recycled.

The goal is to create a lightweight “Unibody” that acts as the phone’s skeleton. This process involves:

-

Deep Pocketing: Creating cavities for the battery, logic board, and Taptic Engine.

-

Thin-Wall Machining: The internal walls separating components can be as thin as 0.5mm to 0.6mm. Achieving this without warping the metal requires advanced toolpath strategies that minimize heat buildup—techniques our engineers at Boona utilize for complex enclosure prototypes.

The “Nano-Molding” & Antenna Challenge

The biggest challenge with a metal unibody is physics: a full metal enclosure acts as a Faraday cage, blocking cellular signals.

To solve this, Apple utilizes a hybrid CNC + Insert Molding process known as NMT (Nano Molding Technology):

-

Slot Machining: The CNC machine cuts precise slots into the frame where the antenna bands will sit.

-

Injection: Specialized plastic resin is injected into these slots.

-

The Re-Machine: The CNC machine returns to mill the metal and the plastic simultaneously.

This results in a surface where you can run your finger across the antenna band and feel absolutely no transition gap. For clients needing to test multi-material assemblies like this, our Vacuum Casting services can simulate overmolded parts effectively during the prototyping phase.

The “Impossible” Details: Ports and Chamfers

The difference between a premium device and a budget one often lies in the holes.

-

Speaker Grilles: If you look closely at the bottom of an iPhone, the speaker holes are not punched; they are individually drilled or milled. They often feature a slight internal taper (conical shape) to improve acoustic performance.

-

Diamond Cutting: For the shiny, chamfered edges found on various models or camera rings, manufacturers use Single-Crystal Diamond (SCD) tools. These tools are so sharp they leave a mirror finish directly off the machine, eliminating the need for polishing.

Comparison: CNC Machining vs. Die Casting for Enclosures

Why does Apple choose slow, expensive CNC over fast Die Casting?

| Feature | CNC Machining (The iPhone Method) | Die Casting (Budget Phones) |

| Material Properties | 100% density, high strength (7075 Al, Ti-6Al-4V) | Porous, lower strength (A380 Al) |

| Surface Finish | Mirror-smooth, ready for anodizing | Rough, requires heavy painting/putty |

| Wall Thickness | Can achieve < 0.6mm reliably | Difficult to go below 1.5mm |

| Tooling Cost | $0 (No molds required) | High ($10k – $50k per mold) |

| Design Flexibility | Instant changes via code | Expensive to modify molds |

Technical Parameters for Precision Enclosures

If you are designing a handheld device and want to achieve the “iPhone standard” of fit and finish, these are the manufacturing parameters you should aim for when working with Boona Prototypes:

-

Dimensional Tolerance: ± 0.01mm to ± 0.02mm (Critical for water resistance sealing).

-

Surface Roughness (Ra): 0.4µm – 0.8µm (Pre-anodize finish).

-

Button Gap Tolerance: 0.03mm (To prevent “button wobble”).

-

Drill Hole Consistency: Position accuracy within 0.05mm.

Conclusion

The iPhone proves that the chassis is not just a holder for components; it is a feature in itself. By utilizing CNC machining, engineers gain structural rigidity, superior thermal management, and an unmatched aesthetic.

You do not need to order a million units to get this level of quality. Whether you need a single prototype or a low-volume run of 500 units, Boona Prototypes brings this “Unibody” precision to your project.

Is your design ready for the metal? Contact us today or upload your CAD files for a quote, and let’s start machining.

FAQs

Why does Apple use CNC machining instead of Die Casting for the iPhone chassis?

Apple prioritizes structural rigidity and cosmetic perfection over cost. Die casting involves injecting molten metal into a mold, which often results in porosity (air bubbles) and a rougher surface that requires heavy finishing. CNC machining carves the part from a solid, cold-rolled block of metal. This results in a part that is denser, stronger, and has a surface finish capable of being anodized directly without flaws—essential for the premium “Unibody” feel.

How does the “Nano-Molding” (NMT) process work for antenna lines?

Metal blocks radio signals, so iPhones need plastic “windows” (antenna lines) for cellular data. The manufacturing process involves:

-

Roughing: CNC machining slots into the metal frame.

-

Injection: Molding plastic directly into those slots.

-

Finishing: CNC milling the entire surface again.

Because the mill cuts both the metal and the plastic simultaneously in the final pass, the transition is seamless to the touch.

Why is machining Titanium (used in iPhone Pro models) more difficult than Aluminum?

Titanium (specifically Grade 5) has low thermal conductivity and is chemically reactive. Heat generated during cutting doesn’t dissipate into the chip; it stays in the cutting tool, causing rapid tool wear. It is also “gummy,” meaning it tends to weld itself to the cutter. Machining titanium requires slower speeds, specialized coolant strategies, and rigid machines—capabilities that Boona Prototypes offers for high-end aerospace and consumer electronic prototypes.

Can I achieve “iPhone-level” tolerances for my own product prototype?

Yes. The tight tolerances Apple uses (often ±0.01mm to ±0.05mm) are achievable with modern 5-axis CNC equipment. Whether you are designing a smartwatch, a medical handheld, or a luxury remote, Boona Prototypes can machine parts to these exact specifications, ensuring your prototype feels like a mass-produced flagship product.

What is the advantage of “Diamond Cutting” on metal edges?

“Diamond Cutting” refers to using a single-crystal diamond tool bit on a CNC lathe or mill. Because natural diamond is incredibly hard and sharp, it shears the metal cleanly rather than tearing it. This leaves a high-gloss, mirror-like finish on chamfered edges (often seen on camera rings or volume buttons) without the need for manual polishing, which could round off the sharp, crisp aesthetic.

How does the machined chassis help with phone overheating?

A CNC-machined unibody, particularly one made of aluminum, acts as a giant passive heat sink. By machining the internal walls to be in direct contact with the logic board (via thermal paste), the metal frame absorbs heat from the processor and dissipates it into the air. This allows the phone to run faster for longer periods compared to a plastic-encased device which insulates the heat.

Is CNC machining suitable for mass production, or just prototyping?

While CNC is the gold standard for prototyping (which we specialize in at Boona), Apple is unique in using it for massive scale production (millions of units). For most other companies, CNC is used for prototyping and low-volume production (1–1,000 units). For mass production of lower-cost devices, companies often switch to die-casting or stamping. However, we can help you bridge that gap with Low-Volume CNC Production runs.