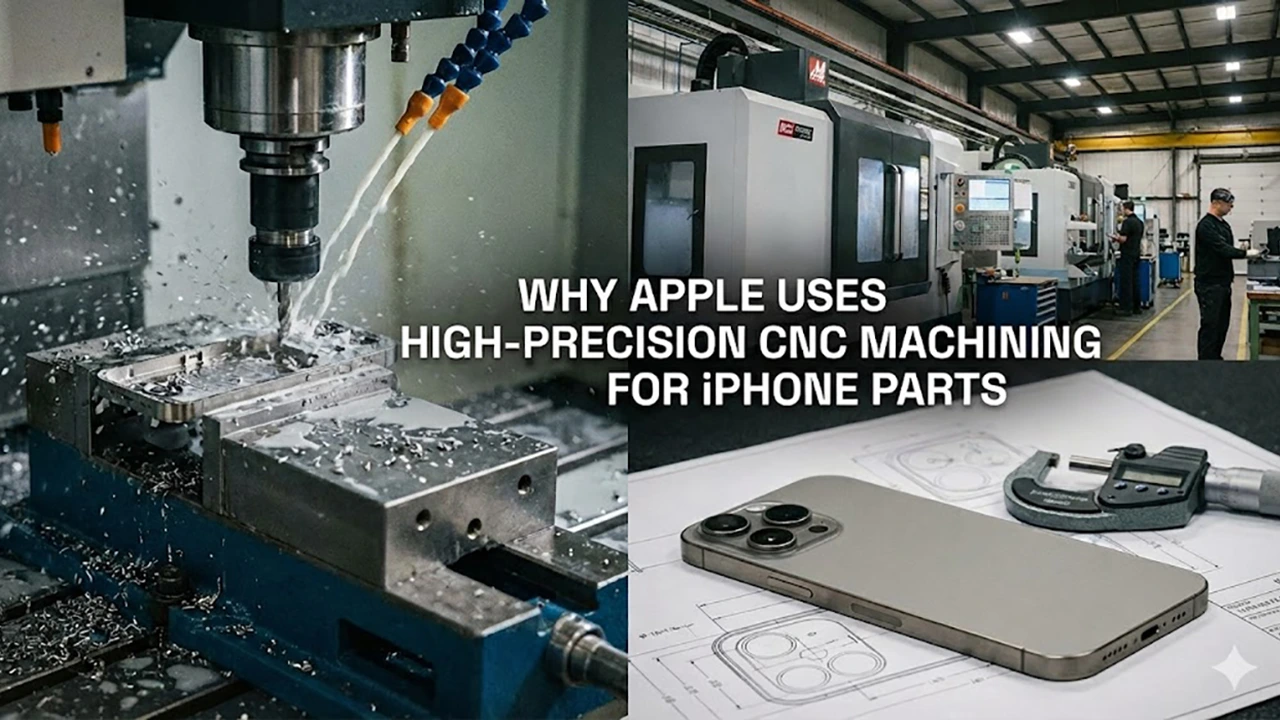

Apple iPhone is widely regarded as one of the most precisely manufactured consumer electronics products in the world. Behind its seamless metal frame, tight tolerances, and premium feel lies a core manufacturing technology: high-precision CNC machining.

For companies specializing in rapid prototyping and low-to-mid volume production, such as Boona Prototypes, Apple approach demonstrates why CNC machining remains irreplaceable in high-end product development. This article explores why Apple relies on high-precision CNC machining, what technical advantages it delivers, and what manufacturers can learn from it.

What Is High-Precision CNC Machining?

What Is High-Precision CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where pre-programmed software controls machine tools to remove material with extreme accuracy.

High-precision CNC machining typically refers to:

-

Tolerances of ±0.01 mm or tighter

-

Exceptional repeatability

-

Superior surface finish

-

Multi-axis (3-axis, 4-axis, 5-axis) machining capability

At Boona Prototypes, CNC machining is widely used for functional prototypes, custom metal parts, and precision assemblies across automotive, electronics, and consumer product industries.

👉 Learn more about CNC capabilities:

https://www.boona-prototypes.com/cnc-machining/

iPhone Parts Manufactured Using CNC Machining

iPhone Parts Manufactured Using CNC Machining

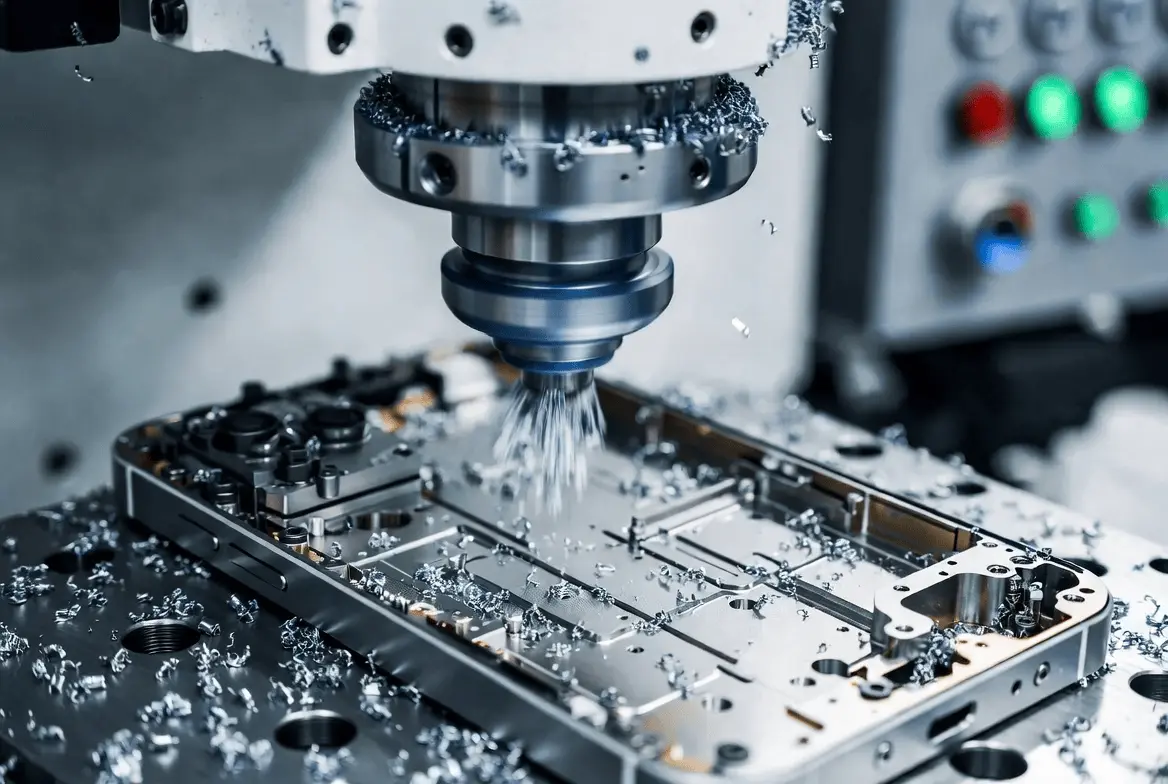

Apple machines a surprising number of iPhone components from solid metal billets rather than relying solely on casting or stamping.

Common CNC-Machined iPhone Components

-

Aluminum or titanium unibody frames

-

Mid-frames and internal structural brackets

-

Button housings and switch components

-

Camera module frames

-

Speaker and microphone grilles

These components require micron-level precision to ensure perfect assembly and consistent performance across millions of units.

Why Apple Chooses High-Precision CNC Machining

Why Apple Chooses High-Precision CNC Machining

Exceptional Dimensional Accuracy

Modern smartphones pack hundreds of components into an extremely compact space. Even a deviation of 0.02 mm can cause assembly failure or performance issues.

Typical CNC Accuracy Used in Smartphone Parts

| Parameter | Typical Value |

|---|---|

| Dimensional tolerance | ±0.005–0.01 mm |

| Hole position accuracy | ≤ ±0.01 mm |

| Flatness | ≤ 0.02 mm |

| Repeatability | ±0.002 mm |

High-precision CNC machining ensures that every frame aligns perfectly with displays, batteries, cameras, and connectors.

Superior Surface Finish and Premium Feel

Apple signature smooth edges and chamfered corners are almost impossible to achieve consistently with stamping or casting alone.

Surface Finish Comparison

| Manufacturing Method | Typical Ra (µm) | Visual Quality |

|---|---|---|

| CNC Machining | 0.8–1.6 | Excellent |

| Die Casting | 3.2–6.3 | Moderate |

| Stamping | 1.6–3.2 | Good |

CNC machining enables:

-

Smooth transitions and fillets

-

Uniform anodizing results

-

Enhanced tactile experience

This aligns closely with Boona Prototypes’ CNC surface finishing services, which support anodizing, polishing, bead blasting, and brushing.

👉 https://www.boona-prototypes.com/surface-finishing/

Structural Strength and Durability

Unlike casting, CNC machining works with solid billets, preserving material integrity and eliminating internal voids.

CNC vs Casting (Structural Comparison)

| Factor | CNC Machining | Die Casting |

|---|---|---|

| Internal porosity | None | Possible |

| Material density | High | Medium |

| Strength consistency | Excellent | Variable |

| Drop resistance | Higher | Lower |

This is especially critical for iPhone frames, which must withstand drops, bending forces, and long-term daily use.

Design Freedom for Innovation

Apple frequently introduces:

-

Ultra-thin walls

-

Complex internal cavities

-

Seamless antenna transitions

These features are only possible with advanced multi-axis CNC machining.

At Boona Prototypes, 5-axis CNC machining enables:

-

Complex geometries in a single setup

-

Reduced machining marks

-

Higher accuracy for intricate parts

👉 Learn more about multi-axis CNC:

https://www.boona-prototypes.com/5-axis-cnc-machining/

Precision Machining of Advanced Materials

Apple has transitioned from aluminum to titanium alloys in recent iPhone models. Titanium offers high strength-to-weight ratio but is notoriously difficult to machine.

Common CNC Materials Used in Smartphones

| Material | Density (g/cm³) | CNC Difficulty | Key Advantage |

|---|---|---|---|

| Aluminum 6061 | 2.7 | Low | Lightweight, cost-effective |

| Aluminum 7075 | 2.8 | Medium | High strength |

| Titanium Ti-6Al-4V | 4.43 | High | Premium durability |

| Stainless Steel | 7.9 | Medium–High | Corrosion resistance |

Boona Prototypes specializes in precision machining of aluminum, titanium, and stainless steel, supporting both prototyping and production runs.

CNC Machining vs Other Manufacturing Methods

CNC Machining vs Other Manufacturing Methods

Why doesn’t Apple use cheaper methods for all components?

| Method | Cost | Precision | Surface Finish | Design Flexibility |

|---|---|---|---|---|

| CNC Machining | High | ★★★★★ | ★★★★★ | ★★★★★ |

| Die Casting | Medium | ★★★ | ★★ | ★★★ |

| Stamping | Low | ★★ | ★★★ | ★★ |

For premium products, CNC machining provides unmatched consistency, which outweighs higher costs.

Apple-Grade CNC Standards at Scale

Apple-Grade CNC Standards at Scale

Apple reportedly operates thousands of CNC machines globally, many customized for:

-

Tool wear monitoring

-

Automated inspection

-

High-speed material removal

Similarly, professional manufacturers like Boona Prototypes apply:

-

In-process inspection

-

CMM measurement

-

Tight process control

👉 Quality and inspection approach:

https://www.boona-prototypes.com/quality-control/

Impact on User Experience

Impact on User Experience

High-precision CNC machining directly affects:

-

Button tactility

-

Camera alignment accuracy

-

Thermal dissipation through metal frames

-

Long-term structural reliability

These details may be invisible—but they define the iPhone experience.

Sustainability and CNC Machining

Sustainability and CNC Machining

While CNC is subtractive, Apple mitigates waste by:

-

Recycling aluminum chips

-

Using recycled aluminum billets

-

Optimizing tool paths to reduce material loss

Boona Prototypes follows similar practices by maximizing material efficiency and supporting sustainable manufacturing workflows.

The Future of CNC Machining in Consumer Electronics

The Future of CNC Machining in Consumer Electronics

As devices become thinner and materials more advanced, CNC machining will continue to evolve with:

-

Ultra-high-speed machining

-

Hybrid CNC + additive manufacturing

-

Smarter automation and AI toolpath optimization

Conclusion

Apple reliance on high-precision CNC machining is not accidental—it is fundamental to product quality, durability, and brand identity. From micron-level tolerances to flawless surface finishes, CNC machining enables the design excellence consumers expect.

For companies developing high-end products or functional prototypes, Apple approach reinforces a clear lesson:

precision manufacturing is a competitive advantage.

With advanced CNC capabilities, multi-axis machining, and strict quality control, Boona Prototypes helps businesses apply the same principles to their own products—from concept to production.

👉 Explore CNC machining services:

https://www.boona-prototypes.com/

FAQs

Why does Apple prefer CNC machining over die casting or stamping for iPhone parts?

Apple prefers CNC machining because it delivers higher dimensional accuracy, superior surface finish, and greater structural strength. CNC machining allows Apple to achieve micron-level tolerances and complex geometries that casting or stamping cannot consistently provide for premium smartphones.

What tolerance levels are required for CNC-machined iPhone components?

Most iPhone structural components require tolerances between ±0.005 mm and ±0.01 mm. Such tight tolerances ensure precise alignment of displays, cameras, batteries, and internal connectors, which is critical for device performance and durability.

Which iPhone parts are most commonly produced using CNC machining?

Common CNC-machined iPhone parts include:

-

Aluminum or titanium unibody frames

-

Internal mid-frames and brackets

-

Camera module frames

-

Button housings and speaker grilles

These components demand high accuracy and excellent surface quality.

Why is CNC machining essential for Apple’s premium surface finish?

CNC machining enables smooth chamfers, rounded edges, and uniform textures, resulting in a high-end tactile feel. The precise toolpaths also ensure consistent anodizing and polishing results across millions of units.

Does CNC machining improve the durability of iPhone frames?

Yes. CNC machining works from solid metal billets, eliminating internal voids commonly found in cast parts. This results in higher structural integrity, better drop resistance, and improved long-term reliability.

Why is 5-axis CNC machining important for smartphone manufacturing?

5-axis CNC machining allows Apple to produce complex geometries and thin-wall structures in fewer setups. This improves accuracy, reduces machining marks, and enables innovative designs that would be difficult or impossible with 3-axis machining.

What materials does Apple machine using CNC technology?

Apple commonly CNC machines:

-

Aluminum alloys (6061, 7075)

-

Titanium alloys (Ti-6Al-4V)

-

Stainless steel

Each material offers different benefits in strength, weight, and durability while requiring advanced machining expertise.

Is CNC machining suitable for mass production, or only for prototyping?

While CNC machining is often associated with prototyping, Apple demonstrates that it can be scaled for mass production using highly automated CNC lines, customized tooling, and advanced quality control systems.

How does CNC machining affect iPhone thermal performance?

CNC-machined metal frames improve heat dissipation by maintaining consistent wall thickness and tight contact with internal components. This helps manage heat from processors and batteries more efficiently.

Is CNC machining environmentally sustainable?

CNC machining can be sustainable when combined with:

-

Recycling of metal chips

-

Use of recycled aluminum billets

-

Optimized toolpaths to reduce waste

Apple and professional manufacturers adopt these practices to minimize environmental impact.

Can CNC machining be used for custom electronics prototypes similar to iPhone parts?

Yes. CNC machining is widely used for custom electronics enclosures, frames, and internal structures, especially during prototyping and low-volume production where precision and fast iteration are critical.

What can manufacturers learn from Apple’s use of CNC machining?

Apple’s approach shows that manufacturing precision directly influences product quality and brand value. Investing in high-precision CNC machining allows companies to achieve better performance, reliability, and premium positioning.