When sourcing custom parts, one of the first questions engineers ask us at Boona Prototypes is: “What is the tightest tolerance you can achieve?”

Whether you are developing a consumer electronic casing or an aerospace component, understanding China CNC machining tolerances is critical for ensuring your parts fit together correctly without incurring unnecessary costs.

In this guide, we break down the standard and precision limits of our machining centers, explain the ISO 2768-mk standard, and offer tips on how to optimize your designs for manufacturing.

What is the “Standard” CNC Tolerance?

In the world of rapid prototyping and low-volume production, “standard” usually refers to the tolerance we can hold without requiring specialized setups, extra inspection time, or post-machining grinding.

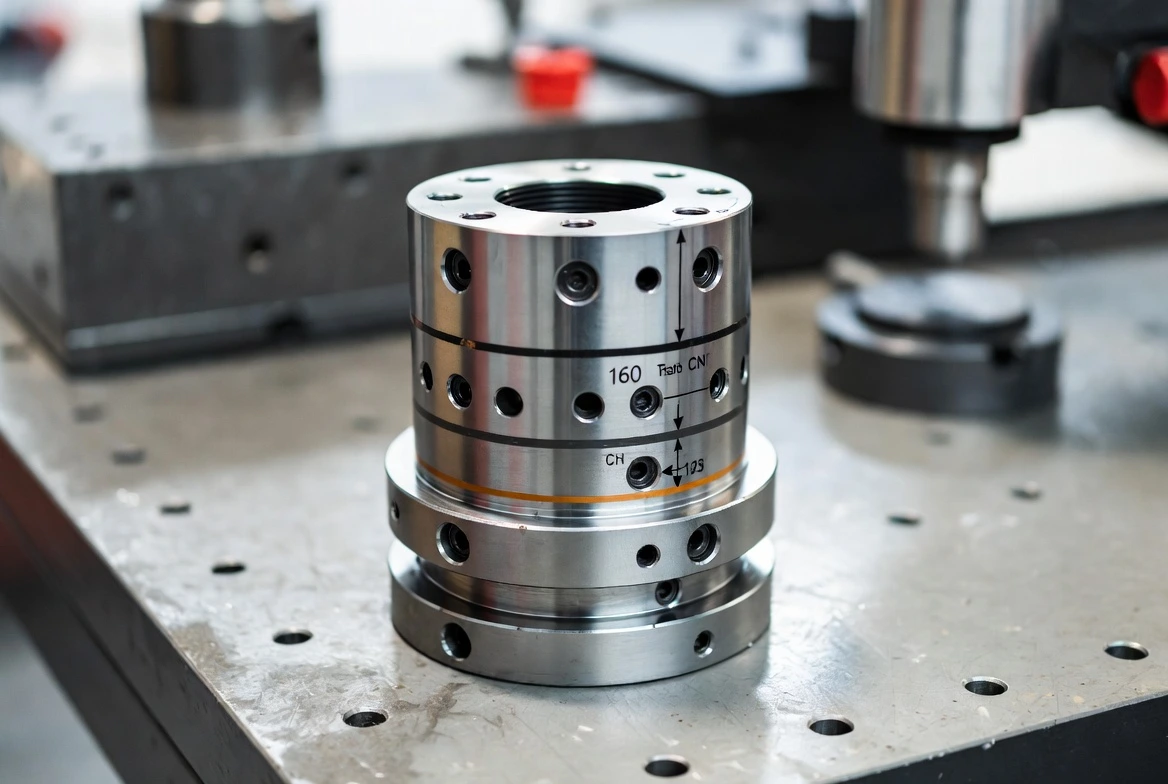

At Boona Prototypes, unless otherwise specified on your 2D drawings, our general CNC milling tolerance standards follow ISO 2768-m (Medium). However, for critical features, our modern 3-axis and 5-axis machines can achieve much tighter specifications.

Table 1: Boona Prototypes General Tolerance Capabilities

| Machining Process | Standard Tolerance (Commercial) | High-Precision Tolerance (Precision) | Typical Surface Finish (Ra) |

| CNC Milling (3-Axis) | ± 0.10 mm (± 0.004″) | ± 0.05 mm (± 0.002″) | 1.6 – 3.2 µm |

| CNC Milling (5-Axis) | ± 0.05 mm (± 0.002″) | ± 0.02 mm (± 0.0008″) | 0.8 – 1.6 µm |

| CNC Turning (Lathe) | ± 0.05 mm (± 0.002″) | ± 0.01 mm (± 0.0004″) | 0.8 – 1.6 µm |

| Wire EDM | ± 0.02 mm (± 0.0008″) | ± 0.005 mm (± 0.0002″) | 0.4 – 0.8 µm |

| Surface Grinding | ± 0.01 mm (± 0.0004″) | ± 0.002 mm (± 0.00008″) | 0.2 – 0.4 µm |

Learn more about our specific CNC Machining Services to see which process fits your project.

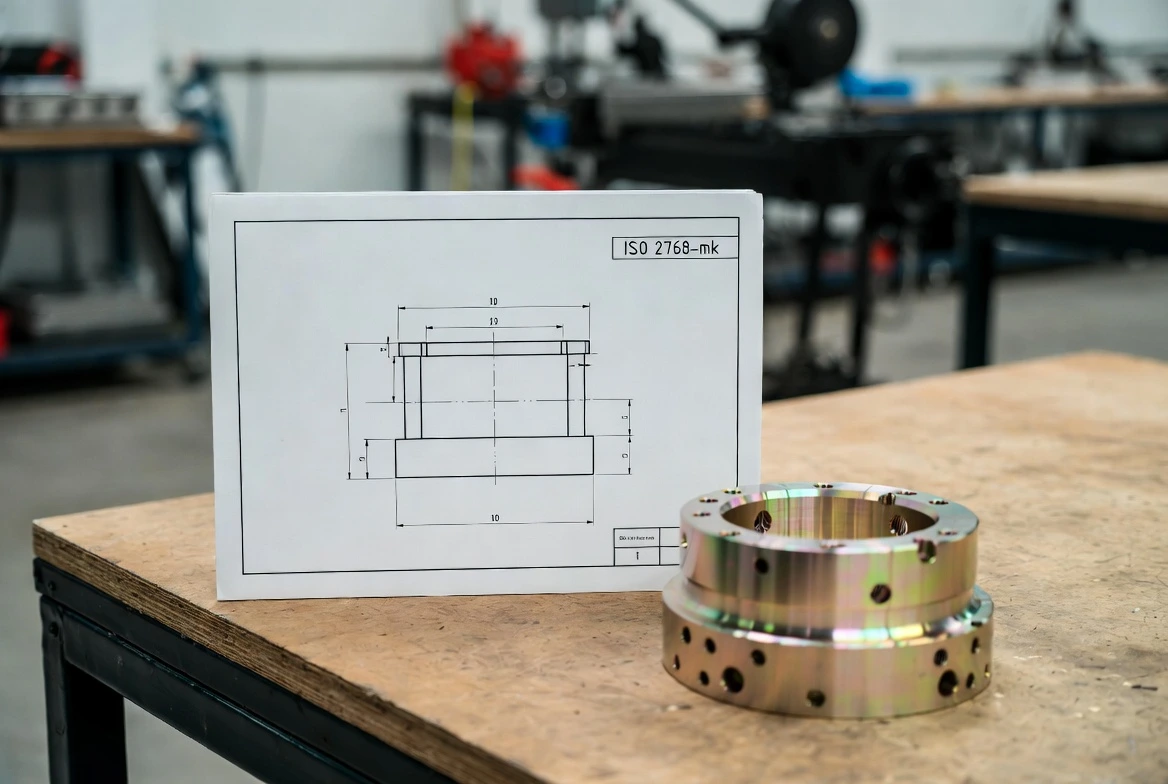

The Gold Standard: ISO 2768-mk

If you upload a 3D CAD file to our system without an accompanying 2D drawing, we apply the ISO 2768-mk standard. This is the industry benchmark for precision machining in China.

-

“m” (Medium): Covers linear dimensions.

-

“k” (Medium): Covers geometric tolerances (flatness, perpendicularity, etc.).

Linear Dimension Tolerances (ISO 2768-m):

-

0.5 to 6 mm: ± 0.1 mm

-

6 to 30 mm: ± 0.2 mm

-

30 to 120 mm: ± 0.3 mm

-

120 to 400 mm: ± 0.5 mm

Tip: For features that require tighter fits than these defaults (such as bearing bores or press fits), you must specify them on a 2D PDF drawing.

Material Matters: Metals vs. Plastics

Achieving tight tolerance machining services isn’t just about the machine; it is about the material. Metals are generally more stable, while plastics are prone to thermal expansion and stress relaxation.

1. CNC Aluminum Tolerances (and other Metals)

Materials like Aluminum 6061, Stainless Steel 304, and Brass are rigid. We can easily hold ± 0.05 mm on these materials. For critical features, we can bore or grind to ± 0.01 mm.

2. Plastic Machining Tolerances

Engineering plastics like ABS, POM (Delrin), and Nylon absorb moisture and react to heat generated by the cutter.

-

Standard Plastic Tolerance: ± 0.10 mm to ± 0.20 mm.

-

Challenge: Long, thin plastic parts may bow or warp, affecting geometric dimensioning and tolerancing (GD&T) compliance.

Check out our Material Selection Guide to choose the right substrate for your precision requirements.

The Cost of Precision: Why “Tighter” Isn’t Always Better

While we pride ourselves on our high-precision capabilities, we advise customers to use tight tolerances only where necessary.

Requesting ± 0.01 mm on every dimension of your part will drive up costs significantly because:

-

Slower Feed Rates: The machine must run slower to reduce vibration.

-

Tool Wear: Tools must be changed more frequently to maintain sharpness.

-

Inspection Time: High-precision parts require CMM (Coordinate Measuring Machine) verification.

Design Advice: Apply standard tolerances (± 0.1 mm) for non-critical surfaces and reserve tight tolerances (± 0.02 mm) for mating surfaces and holes.

Achieving Geometric Perfection (GD&T)

Beyond simple linear numbers, Boona Prototypes also specializes in geometric accuracy. For complex assemblies, typical parameters we achieve include:

-

Flatness: 0.05 mm over 100 mm.

-

Concentricity: 0.02 mm (vital for rotating shafts).

-

Perpendicularity: 0.05 mm.

Conclusion

Whether you need a “look-and-feel” prototype or a production-grade component, Boona Prototypes has the equipment to meet your needs. By understanding the balance between China CNC machining tolerances and manufacturing costs, you can optimize your product development cycle.

Ready to start your project?

Upload your CAD files here for a free quote and design-for-manufacturing (DFM) review today.

FAQs

What is the standard tolerance if I don’t provide a 2D drawing?

If you only submit a 3D CAD model (STEP/IGES), we apply the ISO 2768-m (Medium) standard by default. This generally means a tolerance of roughly ±0.1 mm to ±0.2 mm depending on the size of the feature. If your part requires tighter precision (e.g., ±0.01 mm), you must provide a 2D PDF drawing calling out those specific dimensions.

Can you achieve tighter tolerances than ISO 2768-m?

Yes. For high-precision CNC machining projects, we can achieve tolerances as tight as ±0.005 mm to ±0.01 mm. This usually requires specialized processing, such as precision grinding or Wire EDM, and may incur higher costs due to the slower machining speeds and rigorous CMM inspection required.

Why are tolerances for plastic parts looser than metal parts?

Plastics (like Nylon, ABS, and PEEK) are softer and more susceptible to thermal expansion and deformation during the machining process. Because the material can “relax” or move after being cut, holding a tolerance tighter than ±0.1 mm is difficult and sometimes unstable. Metals like Aluminum and Steel are rigid and hold tight dimensions much more reliably.

Does requesting tighter tolerances increase the cost of my CNC parts?

Yes, significantly. Tight tolerances require:

-

Slower machine feed rates.

-

More frequent tool changes to prevent wear.

-

Specialized jigs and fixtures.

-

100% manual inspection or CMM verification.

-

Cost Tip: Only apply tight tolerances to critical features (like bearing fits or mating holes) and leave non-critical areas to standard tolerances to keep your CNC machining quote competitive.

What file formats should I send to ensure my tolerances are met?

For the best results, please send:

-

3D File (STEP/STP or IGES): Used for programming the CNC machine paths.

-

2D Drawing (PDF): Used to specify critical tolerances, surface finishes, and threaded holes.

Without a 2D drawing, it is impossible for us to know which dimensions are critical to your assembly.

How do you verify that the parts meet my specified tolerances?

We use a range of inspection equipment including calipers, micrometers, thread gauges, and Coordinate Measuring Machines (CMM). Upon request, Boona Prototypes can provide a First Article Inspection (FAI) report or a full dimensional report to verify that the final parts meet your specific CNC manufacturing standards.

What is the difference between geometric tolerance (GD&T) and linear tolerance?

Linear tolerance controls the size (e.g., the diameter of a hole). GD&T (Geometric Dimensioning and Tolerancing) controls the shape and orientation (e.g., how round the hole is, or how perpendicular it is to the base). We can handle complex GD&T requirements—just ensure they are clearly marked on your technical drawings.