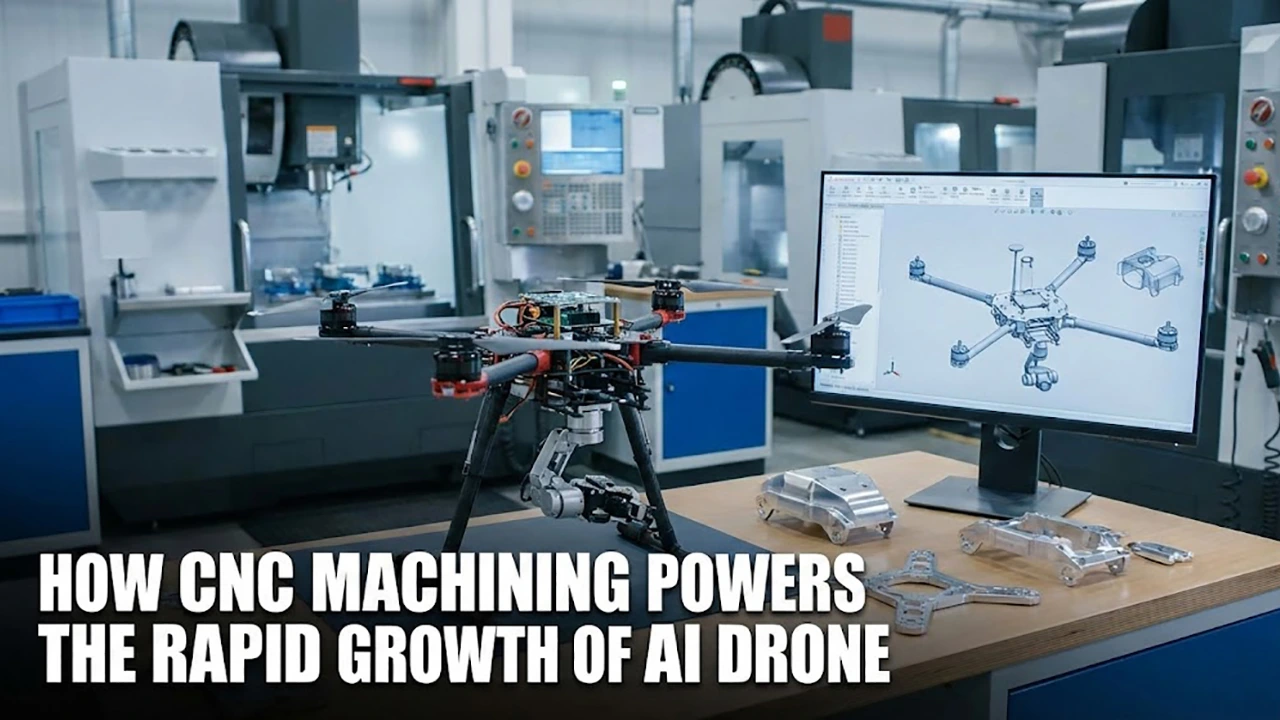

The global AI drone market is experiencing explosive growth, driven by advances in autonomous navigation, computer vision, and edge AI computing. While software and algorithms often take the spotlight, precision hardware manufacturing is the true backbone of AI drone performance.

At the core of this hardware revolution lies CNC machining, enabling manufacturers to produce lightweight, high-strength, and ultra-precise components that AI drones depend on for stability, accuracy, and reliability.

This article explores why CNC machining is essential for AI drone development, from rapid prototyping to small-batch production.

The Manufacturing Challenges Behind AI Drone Innovation

AI drones operate in demanding environments—high vibration, variable temperatures, and long flight durations. This creates strict requirements for mechanical components:

-

Sub-millimeter alignment for AI cameras and sensors

-

Lightweight structures to maximize flight time

-

High rigidity to reduce vibration interference

-

Efficient heat dissipation for onboard AI processors

Traditional manufacturing methods struggle to meet these requirements simultaneously, especially during early-stage development and low-volume production.

This is where CNC machining services become indispensable.

Why CNC Machining Is Ideal for AI Drone Components

Extreme Precision for AI Sensor Accuracy

AI drones rely on cameras, LiDAR, radar, and IMU sensors that must be precisely aligned. CNC machining routinely achieves tolerances of:

| Parameter | CNC Machining Capability |

|---|---|

| Dimensional tolerance | ±0.01 mm |

| Flatness | ≤ 0.02 mm |

| Concentricity | ≤ 0.01 mm |

| Repeatability | ≥ 99.8% |

Such precision ensures stable AI data input, improving object detection, navigation accuracy, and flight control.

Lightweight Yet Strong Materials for Longer Flight Time

Weight reduction directly impacts battery life and payload capacity. CNC machining supports a wide range of high-performance materials used in AI drones:

| Material | Key Properties | Typical Applications |

|---|---|---|

| Aluminum 6061 | Lightweight, corrosion resistant | Drone frames, housings |

| Aluminum 7075 | High strength-to-weight ratio | Motor mounts |

| Magnesium Alloy | Ultra-lightweight | Aerospace drone structures |

| Titanium | High strength, heat resistance | Defense & industrial drones |

| PEEK / Delrin | EMI resistance, lightweight | Sensor brackets |

Learn more about aluminum CNC machining for lightweight drone structures.

CNC-Machined Parts Commonly Used in AI Drones

CNC machining plays a role across nearly every structural system in an AI drone:

| Component | Function | CNC Advantage |

|---|---|---|

| Drone frame | Structural backbone | High rigidity, low weight |

| Motor mount | Stability & balance | Vibration control |

| Camera gimbal | Image stabilization | Tight tolerances |

| Battery enclosure | Safety & cooling | Thermal precision |

| AI processor housing | Heat management | Custom cooling channels |

These parts often require 5-axis CNC machining to achieve complex geometries and undercuts in a single setup.

CNC Machining vs Other Manufacturing Methods for AI Drones

Choosing the right manufacturing process is critical during AI drone development:

| Process | Best For | Limitations |

|---|---|---|

| CNC Machining | Prototypes & small batches | Higher per-part cost |

| Die Casting | Mass production | High tooling cost |

| Injection Molding | Plastic enclosures | Long lead time |

| 3D Printing | Concept models | Limited strength |

For AI drone startups and R&D teams, no-MOQ CNC machining offers the fastest route from design to flight testing.

👉 See how rapid CNC prototyping accelerates drone development cycles.

Rapid Prototyping Accelerates AI Drone Iteration

AI drone innovation depends on fast iteration:

-

Flight test → data feedback → redesign

-

Sensor upgrade → housing redesign

-

Weight optimization → structural adjustment

With CNC machining, design changes can be implemented within days instead of weeks, allowing AI drone companies to stay competitive.

Typical CNC prototyping lead times:

| Stage | Lead Time |

|---|---|

| CAD to CAM | 1 day |

| Machining | 2–5 days |

| Surface finishing | 1–2 days |

| QC & delivery | 1–2 days |

Surface Finishing for Harsh Operating Environments

AI drones often operate outdoors or in industrial conditions. CNC machining supports advanced surface finishes:

-

Anodizing (corrosion resistance)

-

Hard anodizing (wear resistance)

-

Bead blasting (weight & texture control)

-

EMI shielding coatings

These finishes enhance durability while maintaining lightweight performance.

Quality Control Standards for AI Drone CNC Parts

High-end AI drones demand strict quality control:

-

CMM dimensional inspection

-

Material certification (Al, Ti, Mg alloys)

-

ISO 9001 manufacturing standards

-

Assembly-fit verification

Professional suppliers like BOONA CNC machining manufacturer integrate QC into every production step.

CNC Machining Enables Scalable AI Drone Production

As AI drone projects mature, CNC machining bridges the gap between prototyping and mass production:

-

Low-volume production (10–1,000 units)

-

Design validation before tooling investment

-

Cost control during early market entry

This makes CNC machining a strategic manufacturing solution, not just a prototyping tool.

Conclusion: CNC Machining Is the Backbone of AI Drone Growth

From precision sensor alignment to lightweight structural design, CNC machining powers the physical foundation of AI drones. It enables faster innovation, better performance, and smoother scaling—making it essential for the rapid growth of the AI drone industry.

If you’re developing next-generation AI drones, partnering with an experienced CNC machining service provider can significantly shorten development cycles and improve product reliability.

FAQs

Why is CNC machining important for AI drone manufacturing?

CNC machining provides the high precision, tight tolerances, and material strength required for AI drone frames, sensor mounts, and motor components, ensuring stable flight and accurate data capture.

What CNC-machined parts are commonly used in AI drones?

Common CNC-machined AI drone parts include frames, motor mounts, camera gimbals, battery enclosures, sensor brackets, and AI processor housings.

What tolerances are required for CNC-machined AI drone components?

AI drone components typically require tolerances between ±0.01 mm and ±0.05 mm, especially for camera, LiDAR, and IMU sensor alignment.

Which materials are best for CNC machining AI drone parts?

Popular materials include aluminum 6061 and 7075, magnesium alloys for lightweight designs, titanium for high-stress applications, and engineering plastics like PEEK and Delrin.

How does CNC machining improve AI drone flight stability?

CNC machining reduces vibration by producing high-precision motor mounts and rigid structural components, improving flight stability and sensor accuracy.

Is CNC machining better than 3D printing for AI drones?

CNC machining offers greater strength, precision, and surface quality, making it more suitable for functional AI drone parts, while 3D printing is better for concept models.

How fast can CNC-machined AI drone prototypes be produced?

CNC-machined prototypes can typically be produced within 3–7 days, enabling rapid design iteration and real-world flight testing.

Can CNC machining support small-batch AI drone production?

Yes. CNC machining is ideal for low-volume production (10–1,000 units), allowing AI drone companies to scale without investing in expensive tooling.

What surface finishes are used on CNC-machined AI drone parts?

Common finishes include anodizing, hard anodizing, bead blasting, and EMI shielding coatings, improving durability and environmental resistance.

Why do AI drone startups prefer CNC machining suppliers?

AI drone startups choose CNC machining suppliers for no MOQ, fast lead times, design flexibility, and high engineering support during rapid product development.