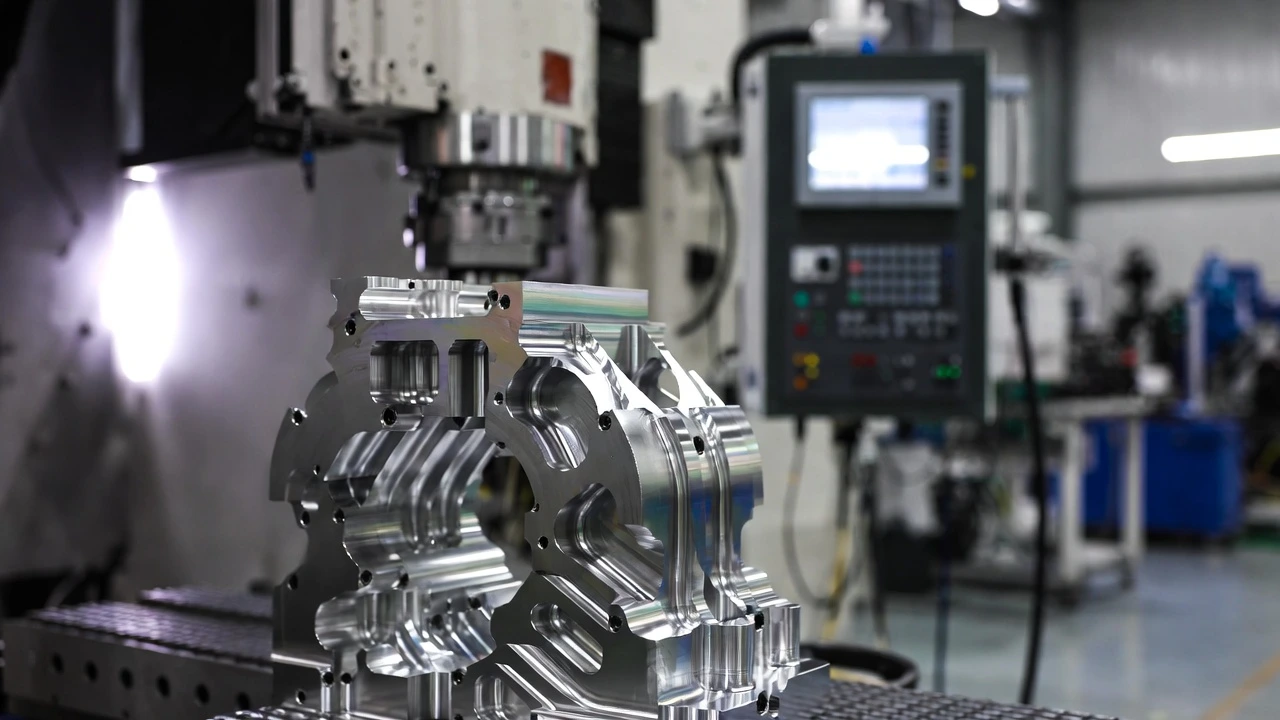

In today’s fast-paced manufacturing landscape, stainless steel CNC machining services for precision parts remain a cornerstone for industries requiring durability, corrosion resistance, and exacting tolerances. Whether you’re developing prototypes or scaling to production, professional precision CNC machining stainless steel parts offers unmatched reliability. Companies like Boona Prototypes, a Shenzhen-based leader in on-demand manufacturing since 2004, exemplify how modern providers deliver high-quality results with no minimum order quantity (NO MOQ), lead times as short as 3 days, and ISO 9001-certified processes.

Why Choose Stainless Steel for Precision CNC Machining?

Stainless steel stands out in high-precision stainless steel parts manufacturing due to its exceptional properties:

- Corrosion Resistance: Perfect for harsh environments like marine or chemical processing.

- Mechanical Strength: High tensile strength (up to 1,500 MPa in some grades) and toughness.

- Thermal Stability: Maintains performance at extreme temperatures.

- Hygiene and Aesthetics: Non-porous surface suits food processing and medical applications.

Providers offering on-demand stainless steel CNC machining services in China, such as Boona, leverage these traits to produce parts with tolerances as tight as ±0.01 mm and rapid turnaround.

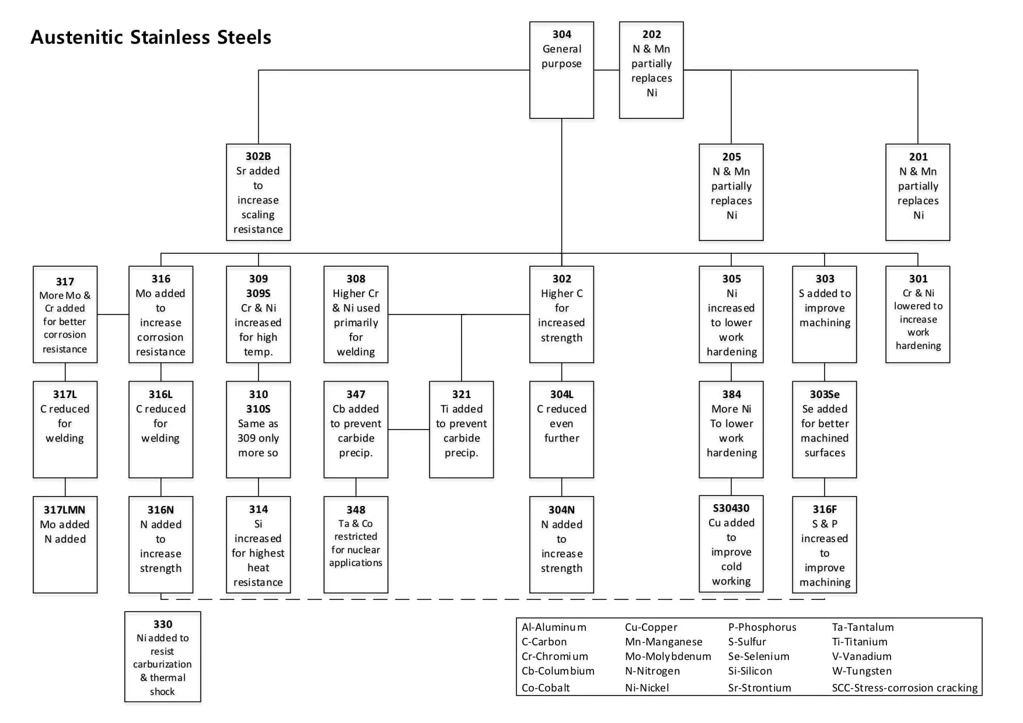

Common Stainless Steel Grades for CNC Machining

Selecting the right grade is critical for corrosion-resistant stainless steel CNC machining. Here’s a comparison table of popular grades used in precision parts:

| Grade | Type | Key Properties | Common Applications | Machinability Rating (1-10) | Typical Yield Strength (MPa) |

|---|---|---|---|---|---|

| 304/304L | Austenitic | Excellent corrosion resistance, formable | Food processing, architectural, medical | 6 | 215 |

| 316/316L | Austenitic | Superior pitting resistance (molybdenum-added) | Marine, pharmaceutical, surgical instruments | 5 | 205 |

| 303 | Austenitic | Free-machining (sulfur-added) | High-volume fittings, shafts | 8 | 240 |

| 410 | Martensitic | Heat-treatable, moderate corrosion | Valves, pumps, cutlery | 7 | 450 |

| 17-4 PH | Precipitation Hardening | High strength, corrosion resistant | Aerospace, defense, turbine blades | 4 | 1,000+ |

This visual chart highlights austenitic family dominance in rapid prototyping stainless steel due to balanced properties.

CNC Machining Processes and Parameters for Stainless Steel

Modern stainless steel CNC machining services employ multi-axis milling, turning, and Swiss-style machining for complex geometries.

Key parameters from leading providers like Boona CNC machining services:

- Tolerances: ±0.01 mm standard; tighter on request

- Surface Finish: As-machined Ra 1.6 μm; polished to Ra 0.4 μm or better

- Part Size Limits: Up to 1200 mm x 800 mm (varies by equipment)

- Lead Times: 3-7 days for prototypes; scalable for low-volume stainless steel production

- Quality Inspections: CMM reports, material certifications, first article inspection

Advantages of Professional Stainless Steel CNC Machining

Opting for no MOQ stainless steel prototypes accelerates innovation. Data shows:

- Up to 70% faster time-to-market with rapid services

- Cost savings of 30-50% versus traditional tooling for low volumes

- Repeatability within ±0.005 mm for production runs

Boona high-volume production capabilities ensure seamless scaling while maintaining precision.

Applications of Precision Stainless Steel CNC Parts

- Aerospace & Defense: Turbine components, fasteners

- Medical Devices: Implants, surgical tools requiring high-precision stainless steel parts

- Automotive: Fuel system fittings, exhaust components

- Food & Marine: Hygienic valves, pumps

Overcoming Challenges in Stainless Steel Machining

Stainless steel’s work-hardening tendency demands optimized parameters: coated carbide tools, proper coolant, and rigid setups to minimize tool wear and achieve superior finishes.

Quality Assurance and Certifications

Reputable providers offer full traceability, including:

- Material mill test reports

- Dimensional CMM inspections

- ISO 9001 compliance (as held by Boona)

Choosing the Right Stainless Steel CNC Machining Service Provider

Look for partners offering affordable stainless steel prototypes in China with global shipping, free DFM feedback, and 24/7 support. Contact Boona Prototypes today for your next project—they specialize in custom stainless steel prototypes and production with no compromises on quality.

In conclusion, stainless steel CNC machining services for precision parts continue to evolve, driven by providers like Boona who combine advanced equipment, expert engineering, and customer-focused flexibility. Whether you need one prototype or thousands of parts, the right service ensures durability, precision, and speed. Ready to start? Explore professional options and bring your designs to life.

FAQs

What makes stainless steel a good choice for CNC machined precision parts?

Stainless steel offers an excellent combination of corrosion resistance, mechanical strength, thermal stability, and hygienic properties. It performs well in harsh environments (marine, chemical, food processing) and maintains tight tolerances without warping. Grades like 304 and 316 are especially popular because they balance machinability with long-term durability.

Which stainless steel grades are most commonly used in precision CNC machining?

The most frequently requested grades are:

- 304/304L – General-purpose, great corrosion resistance, widely used in food and medical applications.

- 316/316L – Superior pitting and crevice corrosion resistance (thanks to molybdenum), ideal for marine and pharmaceutical parts.

- 303 – Free-machining variant for high-volume production.

- 17-4 PH – Precipitation-hardening grade offering very high strength for aerospace and defense components.

- 410 – Heat-treatable martensitic grade for moderate corrosion resistance and higher hardness.

Selection depends on the specific requirements for strength, corrosion resistance, and machinability.

What tolerances can I expect from professional stainless steel CNC machining?

Reputable providers routinely achieve ±0.01 mm (±0.0004″) on standard features, with ±0.005 mm (±0.0002″) or tighter possible on critical dimensions with proper design and fixturing. Advanced 5-axis machines and rigorous quality control (CMM inspection) ensure consistent repeatability.

How long does it take to get stainless steel CNC machined parts?

Prototype quantities can ship in as little as 3–7 days. Low-to-medium volume production typically takes 2–4 weeks, depending on complexity, finishing requirements, and order size. Many on-demand manufacturers (including those with no MOQ policies) prioritize rapid turnaround to support fast iteration cycles.

Is stainless steel difficult to CNC machine compared to aluminum or brass?

Yes, it is generally more challenging due to work hardening, higher cutting forces, and greater heat generation. However, experienced shops overcome this with coated carbide tooling, optimized feeds/speeds, high-pressure coolant, and rigid setups. The result is excellent surface finishes (down to Ra 0.4 μm) and minimal tool wear.

What surface finishes are available for stainless steel CNC parts?

Common options include:

- As-machined (Ra 1.6–3.2 μm)

- Bead blasting for a uniform matte look

- Mirror polishing (Ra ≤ 0.4 μm)

- Passivation to enhance corrosion resistance

- Electropolishing for medical/pharmaceutical applications

Finishing is often included or offered as a seamless secondary operation.

What industries most commonly use precision stainless steel CNC parts?

- Aerospace & defense (fasteners, turbine components, fittings)

- Medical & pharmaceutical (implants, surgical instruments, device housings)

- Food & beverage (hygienic valves, pumps)

- Marine (corrosion-resistant hardware)

- Automotive & energy (fuel system parts, high-pressure components)

How much do stainless steel CNC machined parts cost?

Cost depends on part complexity, material grade, quantity, tolerances, and finishing. Prototypes and low volumes are more affordable than ever thanks to on-demand manufacturing with no minimum order quantity. Expect 30–50% savings versus traditional tooling methods for runs under 1,000 pieces.

What certifications and quality assurance should I look for in a provider?

Key standards include ISO 9001 (general quality management), AS9100 (aerospace), ISO 13485 (medical devices), and ITAR compliance (for defense work). Good shops provide material certificates, first-article inspection reports, and full dimensional CMM reports.

Can I get prototypes with no minimum order quantity (MOQ)?

Yes—many modern CNC shops, especially on-demand manufacturers in China like Boona Prototypes, offer true no-MOQ service. This allows you to order just 1–10 pieces for testing and validation before committing to larger runs.

If you have a specific project or additional questions about stainless steel CNC machining services for precision parts, feel free to share more details!