Precision Machining Services

High-precision CNC machining services for custom parts with exceptional quality and accuracy. We offer advanced manufacturing solutions to meet your exact specifications.

- All uploads are secure and confidential

Certifications

ISO 9001:2015 | ISO 13485:2016 | IATF16949

Why Choose Precision Machining?

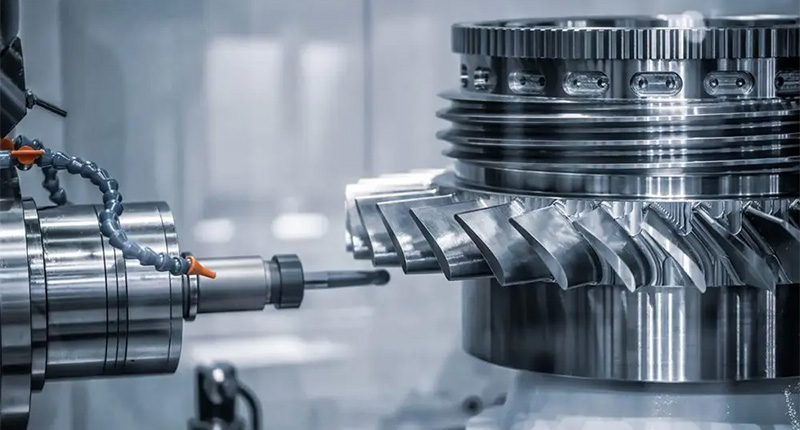

When your project prioritizes part quality over production speed, precision machining is undoubtedly the best choice. It offers tolerances as low as 0.01 mm, providing parts with smooth, refined surfaces and improving overall manufacturing efficiency. Precision machining is ideal for industries such as automotive, aerospace, and medical equipment, producing high-precision components like gears, nozzles, and optical lenses.

Our CNC Precision Machining Technology

BOONA specializes in precision machining of complex small components, utilizing advanced machines and tools that can achieve extremely tight tolerances. Our equipment and technology ensure that every part meets the highest standards of accuracy, catering to a wide range of industry needs.

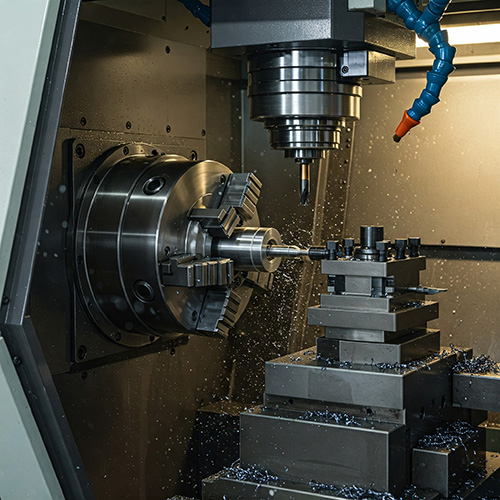

CNC Milling Services

With advanced 3-axis, 4-axis, and 5-axis CNC milling machines, ensuring that every part meets the highest standards of accuracy and quality.

- Material Compatibility: Metals & Plastics

- Operations: Face milling, contour milling, complex surface milling

- Tolerance: ±0.01 mm

- Minimum Part Size: 1 mm × 1 mm

- Maximum Part Size: 4000 mm × 1500 mm × 600 mm

CNC Turning Services

CNC turning is ideal for producing precision components such as shafts, bushings, and threaded parts. It offers unmatched accuracy and repeatability for manufacturing parts and prototypes.

- Material Compatibility: Metals & Plastics

- Turning Operations: Facing, taper turning, drilling, threading

- Tolerance: ±0.01 mm

- Maximum Part Size: 200 mm × 500 mm

- Minimum Feature Size: Φ 0.50 mm

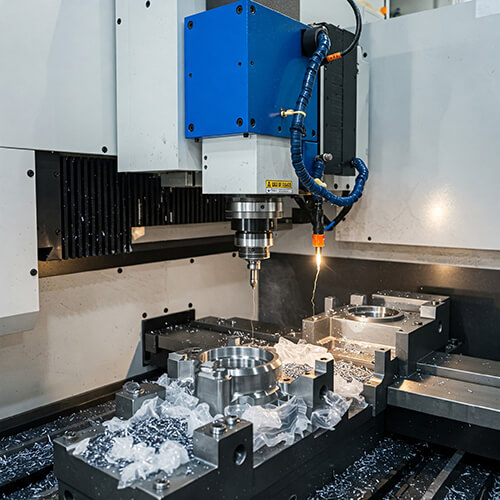

Wire EDM Service

Wire EDM offers high precision, minimal burrs, and is ideal for machining complex shapes in metals like steel and titanium.

- Material Compatibility: Titanium, tool steels, and other metals

- Tolerance: ±0.01 mm

- Maximum Part Size: 400 mm × 300 mm × 200 mm

- Surface Finish: Ra 0.2 µm

- Complex Geometries: Suitable for intricate designs

- Minimal Distortion: Low thermal impact

Micro Machining Services

Ultra-precision manufacturing for small and complex parts with features as small as 1 μm. Provides excellent surface finish and minimal material waste.

- Material Compatibility: Metals, plastics, and ceramics

- Tolerance: ±0.0013 mm

- Surface Finish: Ra 0.05 µm or lower

- Size Range: Ideal for tiny, detailed parts

Swiss Machining Services

Our precision Swiss machining offers custom processes like parting, form turning, threading, and knurling with unmatched precision.

- Accuracy: +/- .001mm

- Concentricity: +/- .0001mm

- 203.2 mm max part length

- 31.75 mm max diameter

- Tolerances as tight as 0.0127 mm

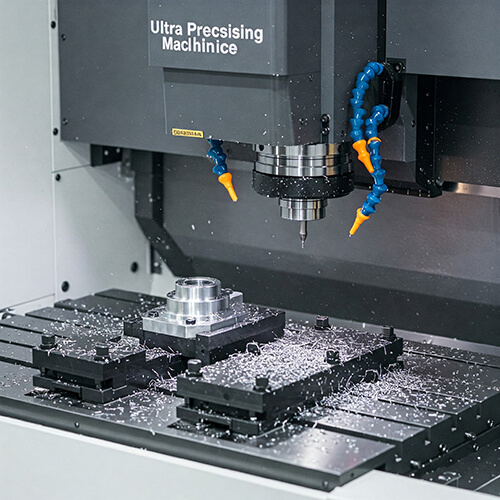

Ultra Precision Machining Services

Ultra precision machining creates intricate parts with sub-micron tolerances, ensuring high-quality finishes for industries like aerospace and medical.

- Sub-micron (0.001 mm)

- Surface Finish: Ra 0.05 µm or better

- Minimum Feature Size: 0.01 mm

- Material Compatibility: Metals, plastics

Select the right precision machining service for your parts needs.

Not sure which precision machining technology is right for your project? Email us at [email protected] to contact our engineers.

Precision Machining Materials & Surface Finishes

We offer a wide range of materials and surface finishes to meet the needs of your precision machining projects. Whether you require metals, plastics, or ceramics, our capabilities ensure high-quality parts with the exact properties you need.

Materials

We offer over 100 certified materials for precision machining, including metals, plastics, and composites. Additionally, we can provide custom materials based on customer requirements.

- Metals (aluminum, steel, titanium, etc.)

- lastics (ABS, PEEK, polycarbonate, etc.)

- Ceramics

Surface Finishing

To ensure each precision machined part achieves optimal durability and aesthetics, we provide a range of advanced surface finishing.

- Anodizing (for aluminum)

- Electropolishing

- Powder Coating

- Chrome Plating

When to Use Precision Machining

Precision machining is a high-precision manufacturing process that achieves strict dimensional and tolerance requirements using advanced CNC machines and specialized tools. It is ideal for complex geometries, fine features, and specialized materials.

Precision machining is used in the following cases:

- For tight tolerances and accurate dimensions.

- For intricate and detailed parts.

- For parts requiring strength and corrosion resistance.

- For high-performance materials like titanium and advanced plastics.

- For small batch production with high quality standards.

Applications of Precision Machining

Precision machining is used in a variety of industries where high accuracy, tight tolerances, and complex geometries are required. Some key applications include:

- Turbine blades

- Engine components

- Transmission parts

- Brake system components

- Medical implants

- Surgical tools

- Diagnostic devices

- Connectors

- Housings

- Heat sinks

- Valve components

Key Benefits of Precision Machining

The key benefits of precision machining include:

- Ensures parts meet strict tolerance requirements.

- Capable of producing intricate designs and shapes.

- Consistency in large production runs.

- Reduces material waste and cost.

- No need for additional polishing or coatings.

- Meets specific design and application needs.

- Parts withstand harsh environments and last longer.

- Fast and efficient production cycles.

- Lowers unit costs for large-scale production.

About Precision Machining FAQs

Yes, we offer free design consultation and help optimize designs for manufacturability, ensuring that parts can be produced efficiently and cost-effectively.

Yes, we offer precision prototyping services for clients looking to test and validate their designs before proceeding to full-scale production.

We provide precision machining services for various industries including aerospace, automotive, medical, electronics, defense, and manufacturing.

Our precision machining services include stringent quality control measures, such as first-article inspections, process capability reports, and final inspections using advanced measuring tools like CMM (Coordinate Measuring Machine).

Absolutely! We’re equipped to handle both low-volume and high-volume production runs, ensuring consistent quality regardless of the batch size.

Essential CNC Machining Resources for Engineers

Latest news, trends and manufacturing design tips for precision cnc machining.