Fast & Affordable Sheet Metal Services

Custom high-precision sheet metal prototypes and parts, as fast as 5 days.

- All uploads are secure and confidential

Certifications

ISO 9001:2015 | ISO 13485:2016 | IATF16949

- Lead time from 5 days

- From 1 to 10,000+ parts

- Wide range of processes available

- ISO and IATF certified

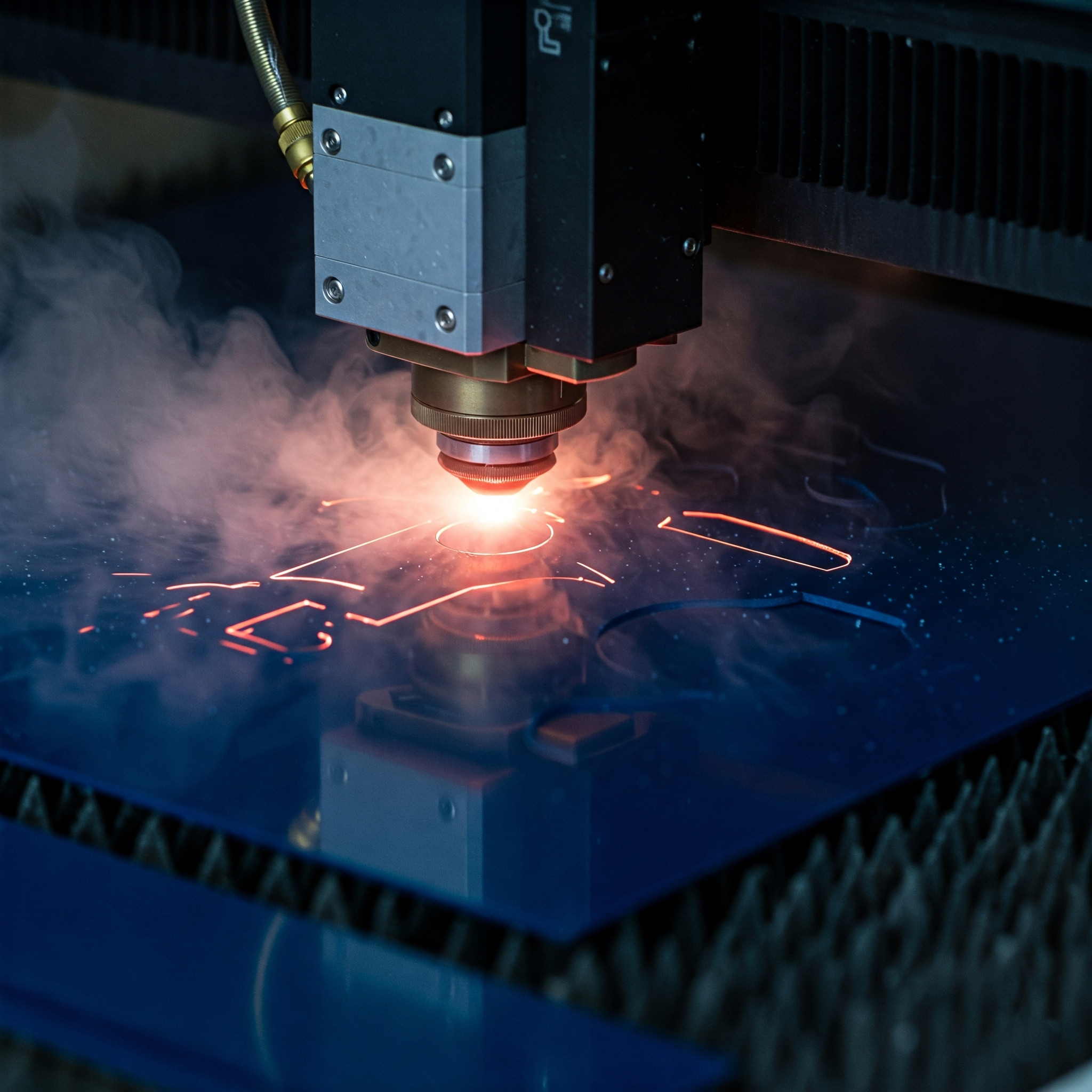

Laser Cutting

We have CNC laser cutting capabilities for high precision parts and prototypes requiring a higher level of detail.

Plasma Cutting

We offer CNC plasma cutting services suitable for both large-scale and one-off custom fabrication projects.

Sheet Metal Bending

Bending is a common sheet metal forming method used to shape steel, stainless steel, aluminium parts after cutting process.

Waterjet cutting

We have waterjet cutting capabilities useful for cutting very thick sheets of metal with a very high-quality finish.

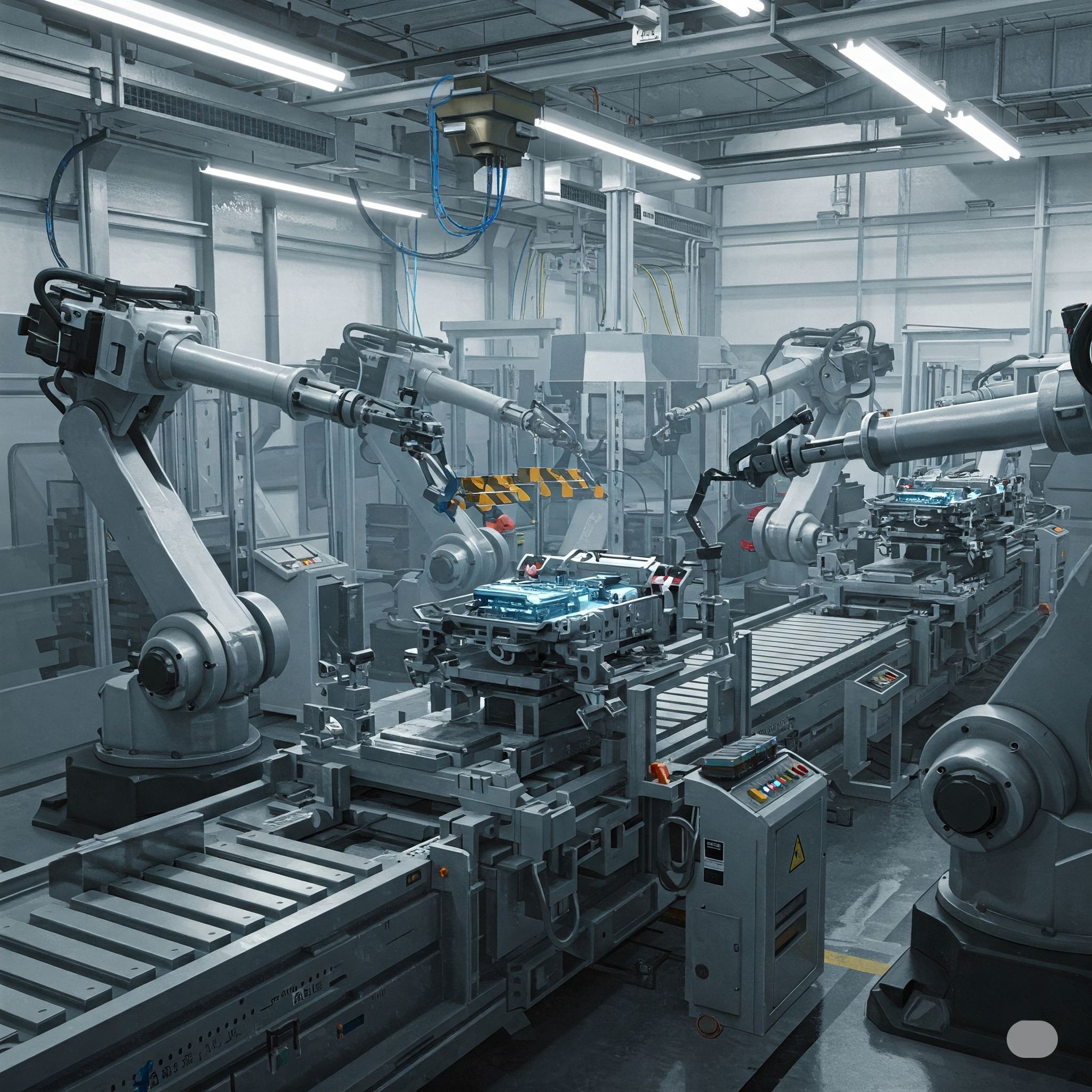

Assembly

We provide sheet metal assembly services using a range of techniques including welding and riveting to assist in streamlining production processes.

Enclosures

Sheet metal fabrication offers an inexpensive, reliable and efficient solution for producing custom enclosures.

Get a quote / Get in touch

Please use the following formats:

.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf and .zip 100mb max file size (per file)

If you have a file type not listed, please contact us to discuss first.

Company Number: Shenzhen Boona Technology Co., Ltd.

Factory: 2/F Fuyong Shanghui Information Bld, Baoan District, Shenzhen, Guangdong Province, China 518132

Sheet Metal Prototyping and Production Services

Our rapid sheet metal prototyping and production services include a variety of tooled and manual manufacturing techniques and processes enabling us to realise some highly complex parts without expensive and time-consuming production tooling. We can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes.

Sheet Metal Materials

Aluminium

Aluminium sheet metal offers excellent strength to weight ratio and corrosion resistance, making it a popular choice in the aerospace and aviation, automotive, and consumer electronics industry.

Copper

Copper is an excellent material for sheet metal fabrication. It is malleable, ductile, and an extremely good conductor of both heat and electricity. It is commonly used for electrical equipment such as wiring and motors.

Low Carbon Steel

Though low carbon steel is weaker and softer, it is good for situations that require structural steel fabrication, such as automobile body components and cans, as it has a very consistent yield strength and is easy to shape.

Cold Rolled Steel (CRS)

At Boona-Prototypes, we can fabricate cold rolled steel sheets. CRS is essentially hot rolled steel that has been further strengthened by being allowed to cool at room temperature and annealed. It produces steel with closer dimensional tolerances and a wider range of surface finishes than hot rolling.

Spring Steel

Spring steel sheet has a low-alloy manganese, medium-carbon steel or high-carbon steel with a very high yield strength. It is a flexible material commonly used to manufacture products, including landing gears, saw blades, springs and more.

Stainless Steel

Stainless steel sheet cut to size is strong and highly resistant to corrosion and rust, making it ideal for parts that are exposed to different elements for long periods and do not easily break.

Steel

At Boona-Prototypes, we can fabricate numerous grades of steel. While working on a low budget, mild carbon steel proves to be the best.

- We provide a quotation of 100+materials so that you can better compare and choose suitable materials.

Typical Sheet Metal Finishes

| Applicable Materials | Colour | Description | |

|---|---|---|---|

| Bead Blasting | All metals | Uniform matte of raw material colour | Bead blasting is used mainly for visual purposes and comes in several different grits which indicate the size of the bombarding pellets. |

| Powder Coating | All metals | Black, white | Powder coating is typically used because it has a longer lasting, tougher finish than painting. |

| Anodizing | All metals | Clear, black, grey, red, blue, gold | Anodising is used to increase surface hardness, wear resistance and durability of metals such as Aluminium. |

Tolerances for Sheet Metal Prototyping

The table below summarises the standard tolerances used at Boona-Prototypes for sheet metal parts.

| Feature | Tolerance |

| Forming or bending | ±0.508mm (0.020″) |

| Bend to edge | ±0.254mm (0.010″) |

| Bend to hole | ±0.381mm (0.015″) |

Get a Quote Within 24 Hours

Send us your 3D CAD and include any quantity, material or surface finish requirements, and our team will get back with a quote within 24 hours. Our comprehensive quote will include your sheet metal part price, shipping cost, lead times, and any remarks raised by our engineers.

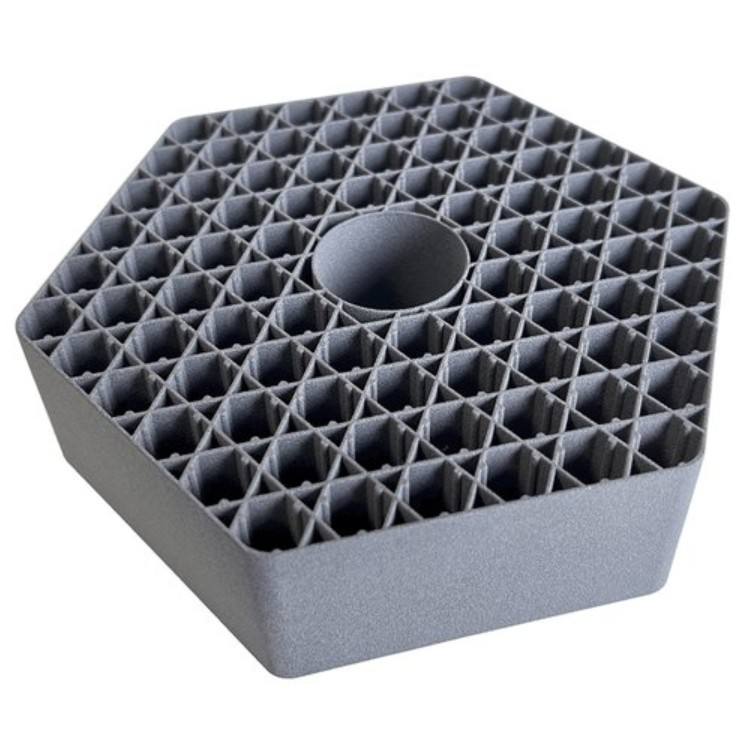

Rapid Sheet Metal Prototyping

We understand the needs of engineers and industrial designers. With full in-house capabilities – bending, laser cutting, welding, as well as CNC folding, tapping, countersinking, counterboring and other processes – we offer unrivalled turnaround on one-off metal prototypes.

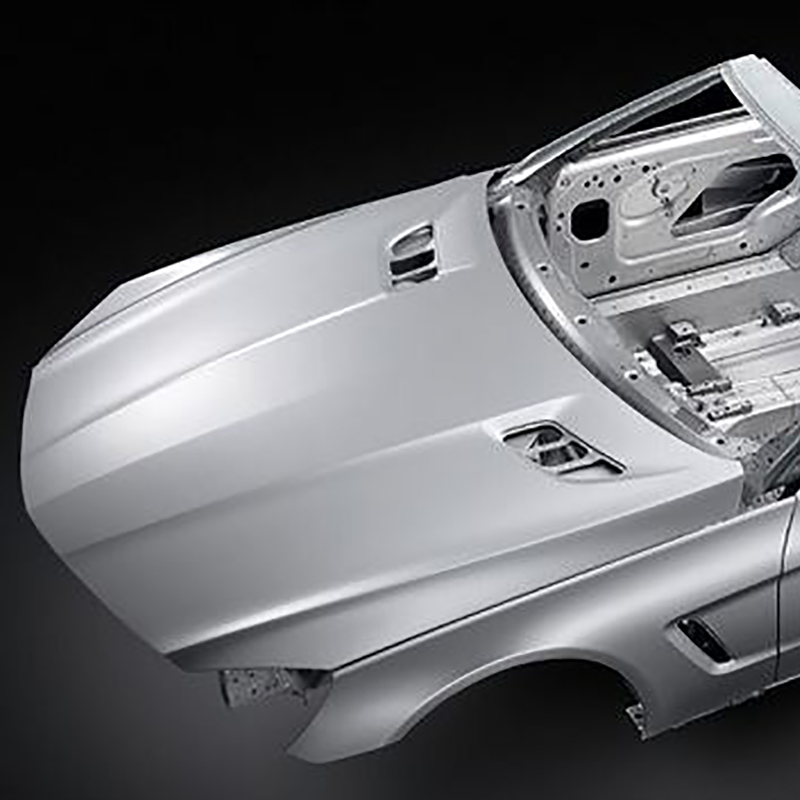

Bespoke Production Parts

We have the experience to produce both simple and complex sheet metal parts for the automotive, aerospace, electronics and many more industries. With no Minimum Order Quantity (MOQ), we provide the flexibility and scalable capacity that your project requires.

Why Use Sheet Metal

Sheet metal can be quickly cut into 2D profile shapes and formed out of a variety of high-strength materials, making it perfect for rapid tooling. Its per-unit pricing lowers significantly in production volumes. Combined with end-use materials and high throughput, sheet metal fabrication is a well-known production method.

Sheet Metal Fabrication is Used For

Rapid prototypes, low volume production, medical and communications products, housings and enclosures, everything from cars and space rockets and planes to air conditioners and soda cans.

Advantages of Sheet Metal Prototyping

- Quick and inexpensive

- High strength and durability

- Very efficient

- High Precision

- Sustainable solution

Sheet Metal FAQs

Sheet metal is a common form of raw metal stock, usually 0.006 and 0.25 inches thick. Fabrication is a collection of processes used to shape raw metal stock into a usable product. Sheet metal prototyping includes many machining processes meant to assemble, cut, or form a sheet metal workpiece. After fabrication, a product often needs to undergo finishing processes. Read the full guide here.

There are 3 common stages in the sheet metal fabrication process, all of which can be completed with various types of fabrication tools. The stages are:

- material removal

- material deformation (forming)

- assembling

Sheet metal prototyping and production solutions are a cost efficient and productive way to make metal parts.

Typically, sheet metal fabrication services can cost anywhere from a hundred dollars up to ten thousands of dollars. The price depends on the raw material cost, part complexity, post processing work involved and cost of labor.

Many industries are heavily reliant on sheet metal rapid prototyping solutions, including:

- aerospace

- automotive

- construction

- electronics

- farming

- transport

Any metal thinner than 6mm is considered sheet metal. Any metal thicker than 6mm is considered a metal plate.