In the fast-evolving automotive industry, rapid prototyping plays a vital role in product innovation. However, no prototype is truly complete without appropriate surface finishing. These finishing processes not only enhance aesthetics but also improve durability, functionality, and readiness for production environments.

This article offers a deep dive into the various surface finishing techniques used in automotive prototypes, focusing on materials, processes, benefits, and how to select the right finish.

I. Why Surface Finishing Matters in Automotive Prototyping

Surface finishing transforms raw prototypes into presentation-ready or functional models. Whether it’s for visual design reviews, aerodynamic testing, or assembly validation, a proper finish ensures the part meets both engineering and user expectations.

At Boona Prototypes, comprehensive surface finishing services are integrated into their rapid prototyping and low-volume production solutions to ensure your parts are production-quality from the start.

II. Common Surface Finishing Techniques

1. Plastic Component Finishing

| Process | Description | Finish Type | Application |

|---|---|---|---|

| Bead Blasting | Abrasive media for texture | Matte | Interior trims, housing components |

| Painting | Solvent or water-based layers | Glossy/Satin/Matte | Display parts, dashboard items |

| Silk-Screen Printing | Layered graphic prints on plastics | Custom Graphic | Buttons, dials, UI indicators |

2. Metal Component Finishing

| Process | Purpose | Benefits | Common Materials |

|---|---|---|---|

| Anodizing | Electrochemical surface oxidation | Corrosion resistance, dyeable | Aluminum |

| Electroplating | Metal layer coating | Conductivity, wear resistance | Steel, Copper, Zinc |

| Polishing | Surface smoothness enhancement | High gloss finish, reduced roughness | Stainless Steel |

| Sandblasting | Uniform matte texture | Improved coating adhesion | All metals |

Boona Prototypes provides post-processing options including anodizing and electroplating, suitable for both visual mockups and functional testing. Learn more about their post-machining finishes here.

3. Advanced Coating Technologies

| Technology | Feature | Common Use Case |

|---|---|---|

| DLC (Diamond-Like Carbon) | High hardness, low friction | Engine parts, sliding components |

| Ceramic Coating | Heat resistance, insulation | Exhaust components, sensors |

| Powder Coating | Durable, eco-friendly | Chassis frames, body panels |

| UV-Cured Paint | Quick curing, high gloss | Lighting fixtures, displays |

Advanced finishes are ideal for pre-production prototypes that undergo thermal, mechanical, or frictional testing. Boona’s ability to apply precision coatings during low-volume production ensures prototypes meet real-world conditions.

III. Surface Finish Selection Criteria

When selecting a finish, consider:

| Factor | Influence on Choice |

|---|---|

| Material Type | Certain finishes like anodizing require Al |

| Functional Goals | Wear, friction, corrosion, or electrical |

| Visual Expectations | Color, gloss, matte, branding |

| Budget | Some coatings are costlier or slower |

| Turnaround Time | Powder coat vs. wet paint, etc. |

Surface finishing is part of Boona Prototypes’ integrated prototyping services, helping clients balance these factors for optimal outcomes.

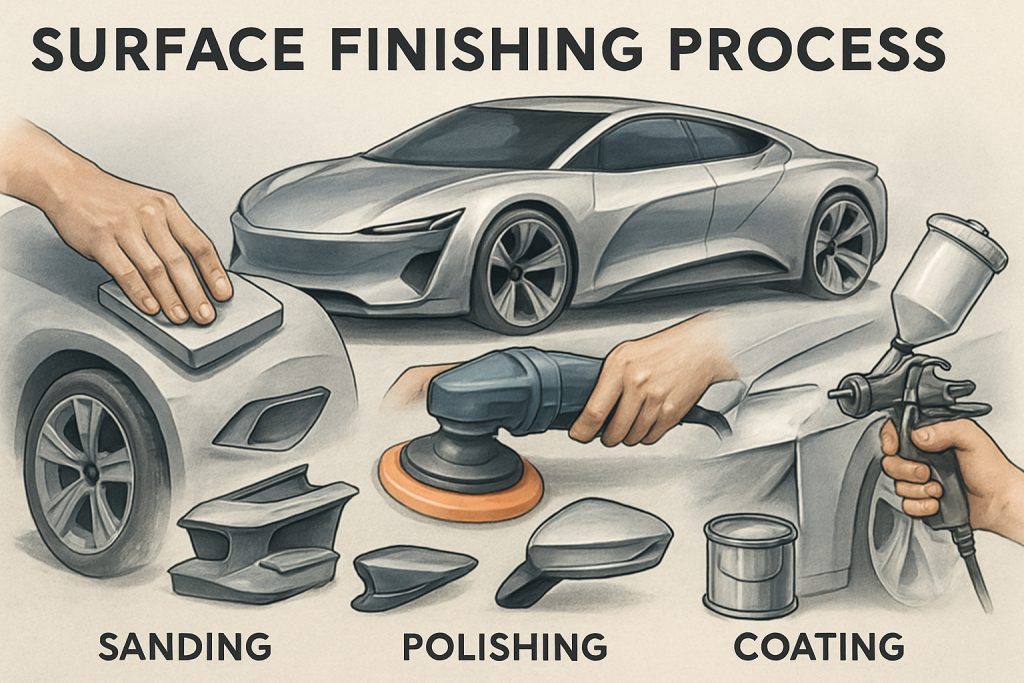

IV. Step-by-Step Surface Finishing Workflow

-

Material preparation – Cleaned, deburred, and machined

-

Surface conditioning – Sandblasting, smoothing, degreasing

-

Primary finish – Mechanical (polishing) or chemical (anodizing)

-

Coating application – Painting, electroplating, or powder coating

-

Final QC inspection – Measuring gloss, thickness, texture, uniformity

At Boona, all processes are done under one roof, ensuring quality and consistency throughout the rapid prototyping and manufacturing chain.

V. Real-World Applications in Automotive Prototypes

-

Optical Lenses: Require polishing to <0.1 µm roughness for clarity

-

Engine Blocks: Anodized and ceramic-coated for durability

-

Dash Panels: Silk-screened, painted with texture matching production units

-

Interior Knobs: Powder coated or plated to replicate OEM feel

With precision manufacturing, Boona helps brands turn 3D files into functional prototypes ready for rigorous automotive testing.

VI. Technical Parameters: Surface Roughness & Tolerance Comparison

| Finish Type | Average Surface Roughness (Ra µm) | Tolerance Capability |

|---|---|---|

| As-Machined | 1.6 – 3.2 | ±0.125 mm |

| Bead Blasted | 3.2 – 6.3 | ±0.2 mm |

| Polished | 0.2 – 0.8 | ±0.05 mm |

| Anodized | Surface-dependent | ±0.1 mm |

| Powder Coated | Adds 0.05 – 0.15 mm thickness | ±0.15 mm |

VII. Emerging Trends in Surface Finishing

-

Nano-finishing: Sub-micron surface control via MAF or chemical polishing

-

Self-healing coatings: Ideal for luxury interiors

-

Low-temp powder coating: Suitable for composite panels or 3D-printed parts

-

Environmentally friendly finishes: Shift to water-based and recyclable media

Boona stays ahead by adopting green, scalable surface treatments that align with modern automotive demands.

Conclusion

Surface finishing is not just the final step — it’s an integral part of the automotive prototyping lifecycle. The right finish ensures your prototype is aesthetically accurate, functionally relevant, and production-ready.

Whether you’re preparing a showpiece prototype or a test-ready part, Boona Prototypes offers end-to-end services including surface finishing, CNC machining, 3D printing, and more. Their one-stop prototyping platform ensures that your parts look and perform like the real deal.

FAQ

1. What is surface finishing in automotive prototyping?

Surface finishing refers to the processes applied to the surface of prototype components to improve their appearance, performance, or durability. Common finishes include painting, polishing, anodizing, bead blasting, and electroplating.

2. Why is surface finishing important in prototype development?

Surface finishing is crucial for:

-

Enhancing aesthetics for design reviews

-

Improving mechanical properties like wear or corrosion resistance

-

Mimicking final production parts for functional testing

-

Ensuring compatibility with other vehicle components

For end-to-end prototyping that includes finishing, Boona Prototypes offers integrated manufacturing services.

3. What types of materials can be surface finished?

Both plastic and metal prototype parts can undergo surface finishing.

-

Plastic: painting, bead blasting, silk-screening

-

Metal: anodizing (aluminum), electroplating (steel, copper), polishing

4. Can I apply surface finishes to 3D printed automotive parts?

Yes. 3D printed parts can be post-processed with sanding, painting, vapor smoothing, and coatings. This improves visual quality and surface strength. Boona’s 3D printing services include optional finishing for a smooth, production-like look.

5. How do I choose the right surface finish for my prototype?

Consider:

-

Material type

-

Function (e.g., visual mockup vs. functional test)

-

Aesthetic requirement

-

Environmental exposure

-

Budget and timeline

Consulting with prototyping experts like Boona Prototypes can help you select the optimal finish.

6. What is the difference between anodizing and electroplating?

-

Anodizing is an electrochemical process that thickens the oxide layer on aluminum, offering corrosion resistance and the ability to add color.

-

Electroplating involves depositing a metal layer (like nickel or chrome) onto a conductive surface, often used for wear resistance or decorative effects.

7. Does surface finishing affect dimensional tolerances?

Yes. Certain finishes like powder coating and plating add measurable thickness (typically 0.05–0.15 mm). Precision machining and proper design allowance are essential. Boona ensures tight tolerances across finishing processes as part of their CNC machining capabilities.

8. How long does surface finishing take for prototypes?

It varies based on the process:

-

Painting: 1–3 days

-

Anodizing: 2–5 days

-

Electroplating: 2–4 days

-

Polishing: 1–2 days

Larger batches or complex geometries may require more time.

9. Can prototypes with surface finishing be used for real-world testing?

Yes. Functional finishes such as anodizing, DLC coating, and thermal spraying are suitable for mechanical, thermal, or corrosion testing, making them ideal for validating part performance before mass production.

10. Does Boona Prototypes offer customized surface finishes for automotive components?

Absolutely. Boona Prototypes provides customized surface finishing solutions tailored to automotive applications, including texture matching, gloss control, functional coatings, and branding elements. Their services ensure your prototypes meet both design intent and testing needs.