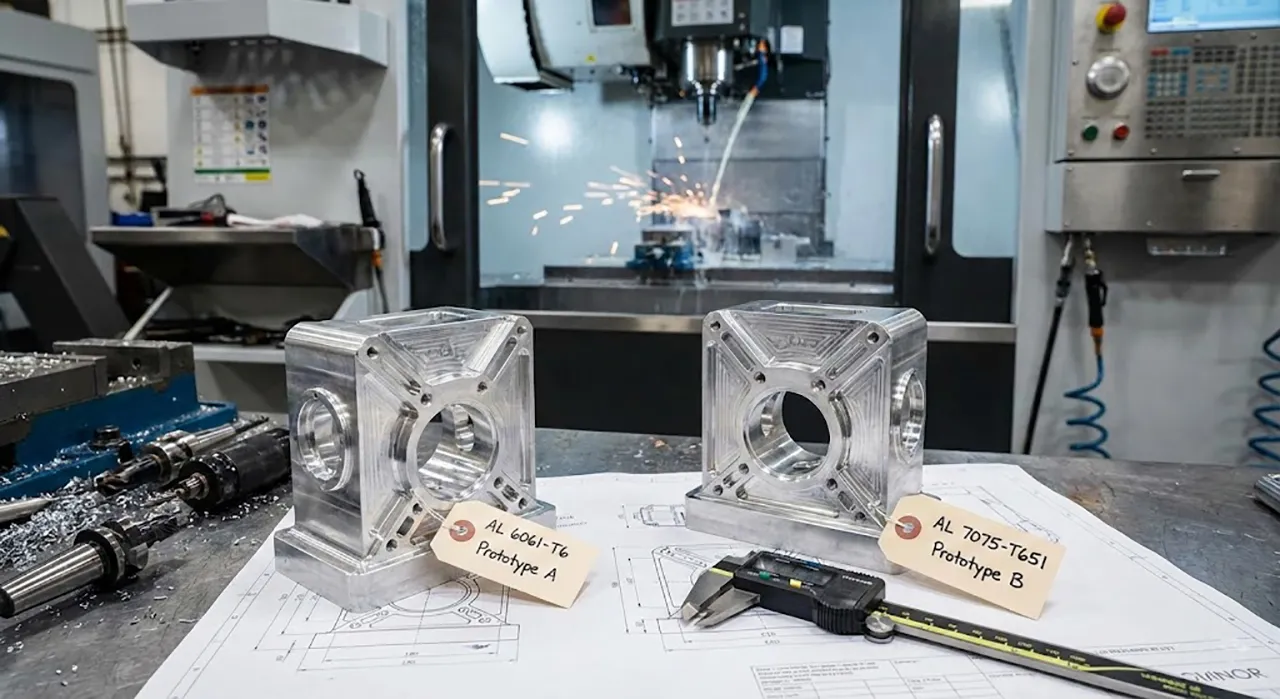

Choosing the right aluminum grade is critical for CNC prototyping services, especially when balancing strength, machinability, cost, and lead time. Among all aluminum alloys, 6061 and 7075 are the two most widely used materials for CNC machined aluminum prototypes across aerospace, robotics, drones, and consumer electronics.

This guide compares Aluminum 6061 vs 7075 for CNC prototyping, helping engineers and product developers select the optimal material without overengineering or overspending.

Why Aluminum Is Ideal for CNC Prototyping

Aluminum alloys dominate CNC prototyping because they offer:

-

Excellent strength-to-weight ratio

-

High machinability

-

Fast CNC milling and turning speeds

-

Compatibility with anodizing and surface finishing

-

Cost efficiency for low-volume CNC prototypes

Companies like BOONA Prototypes CNC machining services specialize in aluminum prototyping to support rapid product development and validation.

Overview of Aluminum 6061 for CNC Prototyping

Aluminum 6061 is a general-purpose structural alloy and the most common material for CNC prototypes.

Key Characteristics of Aluminum 6061

-

Excellent machinability

-

Good corrosion resistance

-

Lower material and machining cost

-

Ideal for complex geometries and tight deadlines

Aluminum 6061 Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 310 MPa |

| Yield Strength | 276 MPa |

| Hardness | 95 HB |

| Density | 2.70 g/cm³ |

| Machinability Rating | 90% |

Best applications:

Rapid CNC prototypes, housings, brackets, enclosures, consumer electronics, and medical device parts.

Overview of Aluminum 7075 for CNC Prototyping

Aluminum 7075 is a high-strength aerospace-grade aluminum, commonly used where structural performance matters.

Key Characteristics of Aluminum 7075

-

Extremely high strength

-

Superior fatigue resistance

-

Lower corrosion resistance than 6061

-

Higher material and machining cost

Aluminum 7075 Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 572 MPa |

| Yield Strength | 503 MPa |

| Hardness | 150 HB |

| Density | 2.81 g/cm³ |

| Machinability Rating | 70% |

Best applications:

Aerospace components, drone frames, automotive performance parts, and load-bearing CNC prototypes.

Aluminum 6061 vs 7075: CNC Machining Comparison

| Feature | Aluminum 6061 | Aluminum 7075 |

|---|---|---|

| Strength | Medium | Very High |

| Machinability | Excellent | Good |

| CNC Tool Wear | Low | Higher |

| Surface Finish | Superior | Good |

| Corrosion Resistance | Better | Moderate |

| Prototype Cost | Lower | Higher |

For functional strength testing, 7075 is preferred.

For design verification and cost-efficient prototyping, 6061 is usually the smarter choice.

Cost Impact in CNC Prototyping

Material choice directly affects CNC machining cost per part.

| Cost Factor | 6061 | 7075 |

|---|---|---|

| Raw Material Cost | Low | +20–40% |

| Machining Time | Faster | Slower |

| Tooling Wear | Minimal | Higher |

| Total Prototype Cost | Lower | Higher |

For startups and R&D teams using rapid CNC prototyping services, 6061 can reduce prototype costs by 15–30% without sacrificing performance.

Surface Finishing & Anodizing Performance

Both aluminum grades support:

-

Clear anodizing

-

Black anodizing

-

Hard anodizing

-

Bead blasting

-

Polishing

However:

-

6061 anodizes more evenly, ideal for cosmetic parts

-

7075 hard anodizing improves wear resistance for structural components

Learn more from BOONA Prototypes surface finishing capabilities.

When to Choose Aluminum 6061 for CNC Prototypes

Choose 6061 if you need:

-

Fast turnaround CNC machining

-

Complex geometries

-

Lower prototype costs

-

Cosmetic-quality surface finishes

-

Functional but non-load-critical testing

Popular long-tail use case:

“CNC machining aluminum 6061 prototypes for electronics enclosures”

When to Choose Aluminum 7075 for CNC Prototypes

Choose 7075 if your prototype requires:

-

High structural strength

-

Fatigue resistance testing

-

Aerospace or drone-grade performance

-

Mechanical validation before mass production

Popular long-tail use case:

“High-strength CNC machined aluminum 7075 drone parts”

CNC Design Tips to Reduce Cost with Aluminum

-

Avoid over-specifying tight tolerances (±0.01 mm only where needed)

-

Add internal corner radii ≥ 1 mm

-

Use uniform wall thickness (≥ 1.5 mm)

-

Select 6061 for early-stage prototypes

BOONA Prototypes’ engineering team provides DFM feedback to optimize aluminum CNC designs before machining.

Conclusion: 6061 vs 7075 for CNC Prototyping

Both aluminum grades are excellent—but for different reasons.

-

6061 aluminum is ideal for cost-effective, fast-turn CNC prototypes

-

7075 aluminum is best for strength-critical, performance-driven testing

Choosing the right alloy early can reduce CNC prototyping cost, shorten lead time, and improve product success.

If you’re unsure, contact BOONA Prototypes for expert material selection and CNC machining support.

FAQs

What is the main difference between 6061 and 7075 aluminum in CNC machining?

The main difference is strength. 7075 aluminum offers significantly higher tensile strength, while 6061 aluminum provides better corrosion resistance, weldability, and lower machining cost.

Which aluminum grade is better for CNC prototyping?

For most CNC prototyping projects, 6061 aluminum is preferred due to its excellent machinability, affordability, and availability. 7075 is better for functional prototypes requiring high structural strength.

Is 7075 aluminum harder to machine than 6061?

Yes. 7075 aluminum is harder and more abrasive, which can increase tool wear, machining time, and overall CNC machining costs compared to 6061 aluminum.

Can 6061 aluminum be used for high-strength applications?

6061 aluminum is suitable for moderate-strength applications, such as enclosures, brackets, and frames. For aerospace or high-load components, 7075 aluminum is typically recommended.

Which aluminum grade is commonly used in aerospace CNC parts?

7075 aluminum is widely used in aerospace CNC machining due to its high strength-to-weight ratio, making it ideal for drone frames, aircraft fittings, and structural components.

Is 7075 aluminum corrosion resistant?

7075 aluminum has lower corrosion resistance than 6061. It often requires surface treatments like anodizing or coating for use in harsh or humid environments.

Does anodizing work better on 6061 or 7075 aluminum?

Anodizing generally produces more consistent and visually uniform results on 6061 aluminum. 7075 can be anodized but may show color variation due to its alloy composition.

Which aluminum grade is more cost-effective for small-batch CNC production?

6061 aluminum is more cost-effective for small-batch CNC machining because of lower material cost, faster machining, and reduced tool wear.

Can 7075 aluminum be used for rapid prototyping?

Yes, but it is usually reserved for late-stage or functional prototypes where performance testing is required, rather than early-stage rapid prototypes.

How do I choose between 6061 and 7075 for my CNC project?

Choose 6061 aluminum for cost-sensitive, general-purpose prototypes. Choose 7075 aluminum for high-strength, load-bearing, or aerospace-grade CNC machined parts.