FPV (First-Person View) drones have exploded in popularity, driven by a passionate community of racers, freestyle pilots, and aerial filmmakers. In this high-speed, high-impact world, the performance and durability of every component matter. Whether you’re ripping through a race course or diving cliffs in freestyle flights, having the right frame and accessories can make the difference between winning and crashing. This is where CNC machining comes in—offering precision, strength, and customization that elevate the FPV drone experience to the next level.

I. Why CNC Machining Is Ideal for FPV Drone Parts

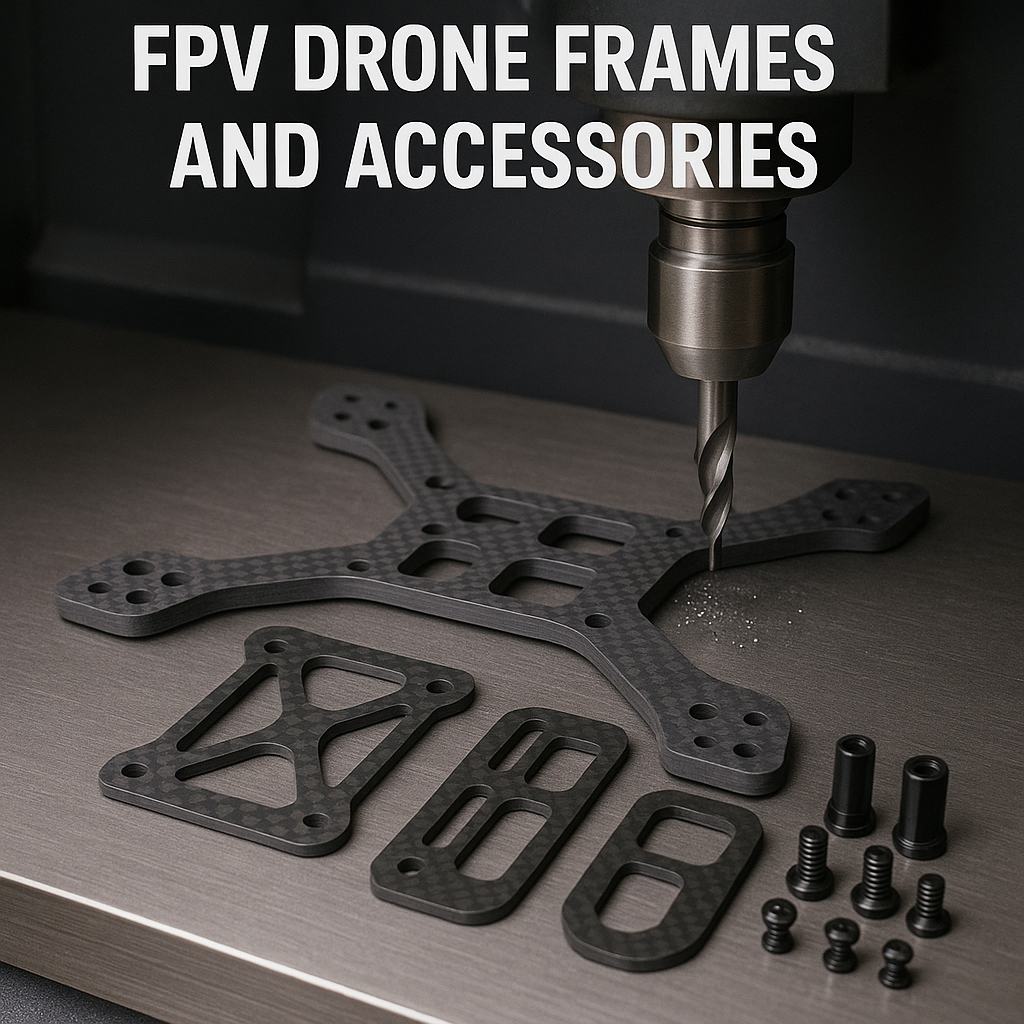

FPV drones demand more than just basic functionality—they need millimeter-level accuracy, rugged durability, and customizability. CNC (Computer Numerical Control) machining meets all of these needs. Unlike injection molding or 3D printing, CNC machining delivers high-precision parts with tight tolerances, ensuring every hole, slot, and edge is exactly where it needs to be. This consistency is vital for frames, mounts, and accessories that affect flight stability and crash survivability.

Additionally, CNC machining is ideal for custom, low-volume production, making it perfect for the FPV community, where pilots often design and tweak their own frames, or buy parts from small boutique brands with unique designs.

II. CNC Machined FPV Drone Frames

The frame is the heart of an FPV drone. CNC machining allows for complex frame arm designs that strike the right balance between weight, stiffness, and strength. Carbon fiber sheets are often CNC-cut into intricate frame shapes with minimal material waste, allowing for:

-

Reinforced motor mounting points

-

Chamfered edges to prevent wire abrasion

-

Perfectly aligned holes for mounting the flight stack and arms

High-precision machining ensures that the center of gravity and geometry of the drone remain consistent, which is critical for smooth flight behavior, accurate tuning, and predictable control.

CNC aluminum is also used for frame parts that require metal reinforcement, such as center plates, camera cages, or arm braces, adding rigidity without significant weight gain.

III. CNC Machined Accessories for FPV Drones

Beyond the frame itself, CNC machining supports a range of accessories that improve functionality, protection, and aesthetics:

-

Camera Mounts: Custom CNC brackets for GoPro, DJI O3, or Insta360 cameras ensure stable mounting and protect lenses during crashes.

-

Antenna Mounts: Precision-cut antenna holders keep FPV and receiver antennas secure and angled correctly for maximum signal reception.

-

Heat Sinks and Covers: CNC aluminum heat sinks are used for video transmitters (VTX) and electronic speed controllers (ESC), helping prevent thermal throttling.

-

Motor Guards & Landing Skids: These CNC-cut parts protect critical components from crash damage, especially during freestyle bashing or rough landings.

All of these parts benefit from CNC machining’s ability to produce strong, lightweight, and purpose-built designs tailored to a pilot’s exact needs.

IV. Material Considerations for FPV Applications

Choosing the right material is essential. Carbon fiber remains the gold standard for FPV drone frames due to its incredible strength-to-weight ratio and vibration damping. CNC machining allows precise cutting of carbon fiber sheets with clean edges and uniform tolerances.

Aluminum alloys (typically 6061 or 7075) are used for brackets, camera cages, and mounts where strength and heat dissipation are required. Aluminum parts can also be anodized, adding not just corrosion resistance but also visual appeal with a variety of color options.

Delrin, nylon, and TPU may also be CNC-machined for non-structural parts where light weight and some flexibility are beneficial.

V. Performance Benefits for FPV Pilots

FPV drones are constantly exposed to crashes, impacts, and vibration. CNC machining ensures:

-

Reduced frame flex, which improves responsiveness and flight characteristics

-

Enhanced durability, meaning fewer broken parts and longer lifespan

-

Accurate part alignment, which supports clean wiring, tight builds, and fewer mechanical failures

For racers and freestyle pilots alike, CNC parts deliver reliability under pressure, whether it’s a split-second turn on the race track or a high-G acrobatic maneuver.

VI. Customization and Brand Identity

CNC machining supports creative freedom. Pilots and frame designers can:

-

Add custom logos or cutouts

-

Design unique geometries for handling or weight distribution

-

Create accessories that match specific flying styles or payload setups

This makes CNC machining ideal not just for performance but also for building brand identity, especially for small FPV frame companies or custom builders.

VII. Choosing the Right CNC Partner for FPV Projects

For DIY pilots or FPV brands, partnering with a skilled CNC manufacturer is essential. Look for a company with:

-

Experience with carbon fiber and aluminum drone parts

-

Tight tolerance control (±0.01 mm or better)

-

Capability for rapid prototyping and small-batch production

-

Surface finishing services like anodizing or edge chamfering

Boona Prototypes is one such CNC partner that offers custom, low-volume, high-precision machining, catering perfectly to the FPV community—from hobbyists to commercial developers.

Conclusion

CNC machining is a cornerstone of high-performance FPV drone builds. From perfectly aligned carbon fiber frames to custom aluminum mounts and precision accessories, CNC technology ensures your drone is flight-ready, crash-resistant, and uniquely yours. As FPV flying continues to evolve, CNC machining will remain the go-to solution for serious pilots who demand speed, control, and reliability in every flight.

FAQs

1. What is CNC machining and how does it relate to FPV drones?

CNC machining (Computer Numerical Control) is a precision manufacturing process that uses computer-guided tools to cut and shape materials. For FPV drones, CNC machining is used to produce high-accuracy components like carbon fiber frames, aluminum camera mounts, and custom accessories that directly impact flight performance and durability.

2. Why is CNC machining important for FPV drone frames?

CNC machining allows for:

-

Precise cuts and consistent dimensions for better fit and flight geometry

-

Customization of frame shapes, logos, and mounting points

-

Durability with chamfered edges and high-strength materials like carbon fiber and aluminum

This results in smoother flight, reduced vibration, and more resilient drones in crashes.

3. Which FPV drone parts are commonly CNC machined?

CNC machining is used for:

-

Carbon fiber frame plates (top plate, bottom plate, arms)

-

Aluminum camera cages and mounts

-

Battery protectors, heatsinks, motor guards, antenna holders

-

GoPro and action camera brackets

These parts benefit from precision, strength, and design flexibility.

4. What materials are best for CNC-machined FPV parts?

-

Carbon Fiber: Lightweight, stiff, and vibration-resistant; ideal for frames.

-

Aluminum Alloys (6061, 7075): Used for brackets, mounts, and heat-dissipating components.

-

Delrin or Nylon: Suitable for flexible or impact-resistant accessories.

-

Anodized Aluminum: Adds corrosion resistance and color customization.

5. Can CNC machining improve FPV drone durability?

Yes. CNC machining ensures:

-

Stronger frame construction with exact fit

-

Clean, reinforced edges that reduce cracking

-

Crash-resistant mounts and guards, which help protect sensitive components like cameras and VTXs

This significantly reduces repair frequency and extends drone lifespan.

6. Is CNC machining suitable for hobbyists or small FPV brands?

Absolutely. CNC machining is ideal for:

-

Custom one-off builds

-

Low-volume production for boutique frame designers

-

Rapid prototyping of new designs

Services like Boona Prototypes support both individual pilots and small drone brands with fast, flexible, and cost-effective solutions.

7. What are the advantages of CNC over 3D printing for FPV drone parts?

| Feature | CNC Machining | 3D Printing |

|---|---|---|

| Strength | High (metal, carbon) | Moderate (depends on filament) |

| Precision | Very high | Medium |

| Surface Finish | Smooth, professional | Layered texture |

| Material Choice | Metal, carbon fiber, Delrin | Plastics, TPU, resin |

For structural or performance-critical parts, CNC machining is preferred.

8. Can I customize my FPV frame or accessories with CNC machining?

Yes! CNC machining allows:

-

Custom frame geometries

-

Engraved logos or call signs

-

Mounts tailored for specific cameras or VTX setups

-

Color anodizing for unique finishes

Perfect for pilots who want personalized gear or brand differentiation.

9. How fast can CNC drone parts be manufactured?

Turnaround time depends on complexity and order size. For most FPV drone parts:

-

Prototypes: As fast as 2–5 days

-

Production runs: Usually within 7–10 days

This speed is ideal for fast development and repairs between race events or flights.

10. Where can I order CNC machining services for FPV drone parts?

You can order custom FPV drone parts from trusted providers like Boona Prototypes, who offer:

-

Precision CNC machining

-

Support for carbon fiber and aluminum

-

Fast prototyping and global shipping

Perfect for racers, freestyle pilots, and custom frame designers.