In the world of modern manufacturing, CNC (Computer Numerical Control) machining plays a critical role in producing precision components for various industries. Two of the most common CNC processes—milling and turning—each offer unique advantages. But how do you decide which one is best for your project?

Whether you’re creating a single prototype or scaling to full production, understanding the strengths of each process can help you save time and cost while maximizing product performance. In this guide, we’ll walk through the fundamentals of CNC milling and turning and help you choose the most suitable option for your needs.

I. What Is CNC Milling?

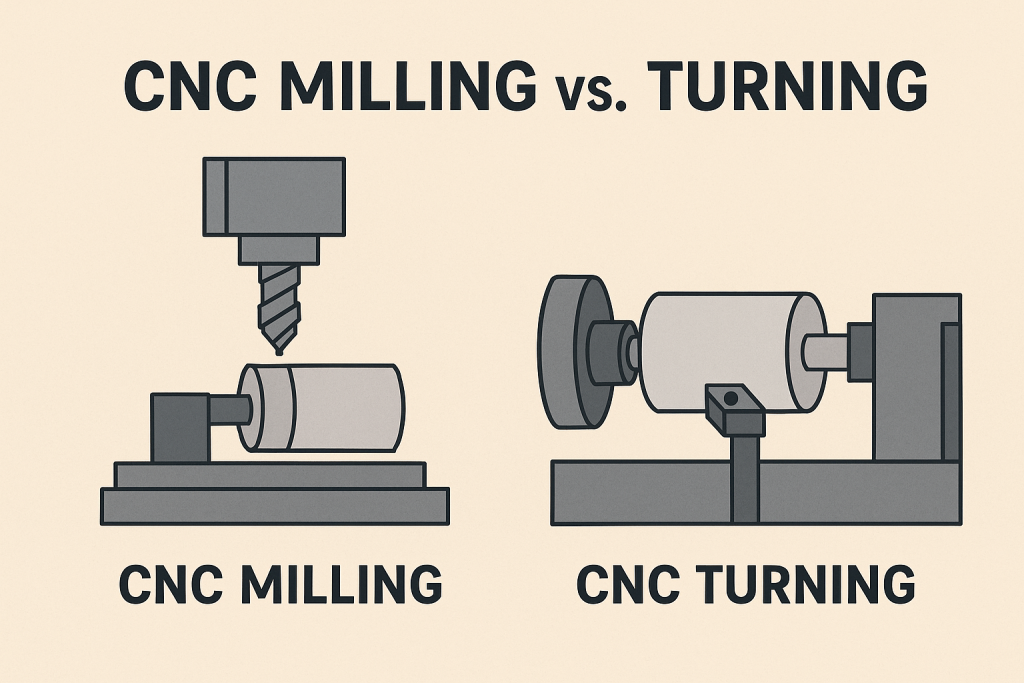

CNC milling is a subtractive manufacturing process that uses rotating multi-point cutting tools to remove material from a stationary workpiece. Machines typically operate on 3 to 5 axes, allowing for complex geometries and high precision.

Boona Prototypes’ CNC milling services utilize advanced machines capable of tight tolerances, ideal for producing parts like housings, brackets, enclosures, and more. From aluminum and steel to plastics and composites, CNC milling accommodates a wide range of materials and finishes.

Key benefits of CNC milling:

-

Precise 3D contouring

-

Suitable for prismatic or complex shapes

-

Versatile material compatibility

-

Ideal for prototyping and low- to mid-volume production

II. What Is CNC Turning?

CNC turning is used to create cylindrical or rounded parts by rotating the workpiece against a stationary, single-point cutting tool. This process is efficient and cost-effective for components like shafts, rods, pins, and bushings.

At Boona Prototypes, our CNC turning machines provide high-speed, high-precision solutions for round and concentric parts. With options for both external and internal turning, as well as threading and grooving, our CNC turning capabilities are ideal for applications in automotive, aerospace, and medical sectors.

Advantages of CNC turning:

-

High-speed production for cylindrical parts

-

Superior roundness and surface finish

-

Efficient for high-volume runs

-

Compatible with hard and soft metals

III. CNC Milling vs. Turning: Key Differences

| Feature | CNC Milling | CNC Turning |

|---|---|---|

| Tool Movement | Cutting tool rotates, workpiece fixed | Workpiece rotates, tool is stationary |

| Best for | Complex surfaces, slots, pockets | Cylindrical parts, threads, bores |

| Number of Axes | 3, 4, or 5 axes | Typically 2 axes (X and Z) |

| Surface Precision | Excellent for flat and angled faces | Best for concentric accuracy |

| Tool Types | Multi-point cutters | Single-point tools |

IV. When to Use Milling or Turning

-

Choose milling if your design includes contours, pockets, angles, or needs machining on multiple faces. It’s perfect for electronics housings, bracketry, or customized tooling.

-

Choose turning when producing symmetrical parts like pulleys, sleeves, or connector pins—especially if speed and volume matter.

-

Consider hybrid machining for parts that require both round and flat features. Many advanced setups combine both processes to reduce handling and setup time.

At Boona Prototypes, we also offer combined CNC services to support complex projects where both turning and milling are required in a single operation.

V. Real-World Applications

-

CNC milling is commonly used in creating electronic enclosures, robotic arms, jigs and fixtures, and medical device casings.

-

CNC turning is ideal for making valves, drive shafts, pins, rotors, and fasteners.

-

In sectors like aerospace and automotive, many parts are milled and turned as part of an integrated process to ensure efficiency and precision.

VI. Industry Trends: Smarter Machining

With the advent of multi-axis machines, automated tool changers, and integrated CAD/CAM systems, CNC technology is rapidly evolving. Manufacturers are embracing hybrid machines that can both mill and turn in a single cycle, enhancing speed and accuracy while reducing operator intervention.

Boona Prototypes continues to invest in the latest technologies, ensuring our clients benefit from efficient and scalable production solutions. Learn more about our commitment to rapid prototyping and custom manufacturing.

Conclusion

Choosing between CNC milling and turning depends on:

-

Geometry of the part

-

Volume of production

-

Tolerance requirements

-

Budget and lead time

If your part is rotational and symmetrical, go with turning. If it requires complex features or multiple faces, milling is likely the better choice. For parts that have both, talk to a manufacturer with hybrid or full-service capabilities.

Need expert help deciding? Contact Boona Prototypes today for a free design consultation and get your project into production with confidence.

FAQs

1. What is the main difference between CNC milling and CNC turning?

The main difference lies in motion: In CNC milling, the cutting tool rotates while the workpiece remains stationary. In CNC turning, the workpiece rotates while a stationary cutting tool removes material. Milling is ideal for flat and complex geometries, while turning is best for cylindrical parts.

2. Which process is more precise—milling or turning?

Both processes offer high precision, but CNC turning often achieves better roundness and concentricity for cylindrical parts. CNC milling excels at achieving flatness and intricate surface details. The right choice depends on the part geometry.

3. Can a single part be both milled and turned?

Yes, many parts require both turning and milling operations. At Boona Prototypes, we provide hybrid machining solutions that combine both processes in one setup to ensure accuracy and reduce production time.

4. What types of parts are best suited for CNC turning?

CNC turning is ideal for parts with rotational symmetry, such as shafts, bushings, spacers, pins, and threaded components. It’s commonly used in the automotive, aerospace, and medical industries.

5. When should I choose CNC milling instead of turning?

Choose CNC milling when your part includes slots, pockets, angled cuts, or complex contours. It’s the better option for brackets, housings, plates, and prototypes that require multiple faces to be machined.

6. Which process is faster—milling or turning?

For cylindrical parts, CNC turning is usually faster due to the simplicity and high-speed capability of the setup. CNC milling may take more time due to tool changes and complex tool paths, especially on multi-axis machines.

7. What materials can be used in CNC milling and turning?

Both processes support a wide range of materials, including aluminum, stainless steel, brass, titanium, POM, ABS, and nylon. Boona Prototypes offers material-specific guidance based on your design and tolerance requirements.

8. How do I know which CNC process is right for my prototype?

Start by evaluating the shape, tolerance, and features of your design. If the part is primarily cylindrical—go with turning. If it has complex or prismatic features—choose milling. Still unsure? Contact Boona Prototypes for a free consultation.

9. Are both CNC milling and turning suitable for mass production?

Yes, both are scalable. CNC turning is especially efficient for high-volume production of simple shapes. CNC milling supports both small batch and mid-volume runs, especially when flexibility is needed for design changes.

10. Does Boona Prototypes offer combined CNC services?

Absolutely. Boona Prototypes offers full-service CNC machining, including milling, turning, and hybrid operations to meet diverse customer needs—from prototypes to final production.