CNC Turning Services

Get quality custom turned parts in a matter of days. From rapid prototyping to production, our on-demand manufacturing platform can provide high-quality metal and plastic CNC turning parts.

- All uploads are secure and confidential

Certifications

ISO 9001:2015 | ISO 13485:2016 | IATF16949

Precision CNC Turning Services

With BOONA powerful CNC lathes and turning centers, we provide customized prototypes and end-use parts for your project. From flat to radial and axial holes, grooves, and grooves, you can obtain durable various types of turning parts in just 3 days. We are committed to efficiently and effectively delivering customized turning parts for precision manufacturing, whether it is metal or plastic materials. Just upload your 3D CAD file to get the part quotation.

Precision CNC Turning Tolerance

View our CNC turning strict tolerance requirements:

| Metric units | Imperial units | |

|---|---|---|

| Linear Dimension | ±0.025 mm | ±0.001 in. |

| Shaft Diameters | ±0.02 mm | ±0.0008 in. |

| Hole Diameters (Not Reamed) | ±0.02 mm | ±0.0008 in. |

| Tolerances | ±0.01 mm | ±0.0004 in. |

- BOONA accepts a maximum size of 200 × 500mm turning parts. If you have larger parts, Please contact the [email protected]

CNC Turning Materials

Various CNC turning options for metal and plastic parts are available, if you don’t see what you need, Please contact the [email protected]. We can purchase according to your project specifications.

| Available Varieties | |

|---|---|

| Aluminium | Aluminum 5052,Aluminum 7075,Aluminum 7075-T6,Aluminum 6063-T5,Aluminum 7050-T7451,Aluminum MIC-6,Aluminum 6061-T6,Aluminum 2024-T3 |

| Brass | Brass C360,Brass 260 |

| Copper | Copper C110,Copper 101 |

| Stainless steel | Stainless Steel 303,Stainless Steel 304,Stainless Steel 316/316L,Stainless Steel 416,Stainless Steel 420 |

| Alloy Steel | Alloy Steel 4130,Alloy Steel 4140, |

| Titanium | Titanium Grade 2,Titanium 6Al-4V |

| Plastics | ABS, Acrylic, Nylon, PEEK,Polycarbonate, Polypropylene, Polyethylene |

CNC Turning Surface Finishes

Achieve the perfect finish for your CNC-turned parts with our range of surface treatment options.

Anodized

Specific to aluminum, this finish can range from smooth to matte or gloss, with customizable colors. A thin layer (0.002mm to 0.04mm) is removed.

Polishing

The polished finish offers a high gloss, smooth surface with Ra 0.8μm (Ra 32μin) roughness, ideal for mirror-like applications.

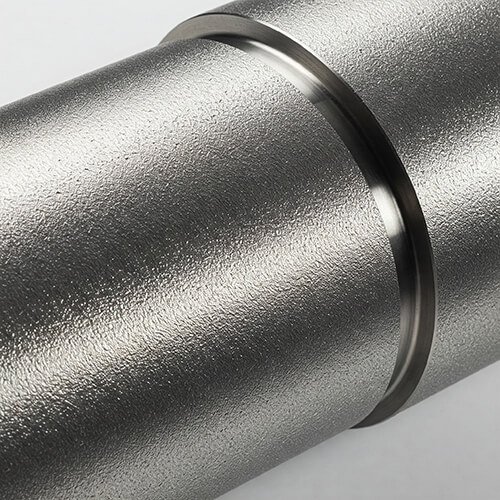

Bead Blasting

Metals or plastics parts surface is left with a smooth, matte appearance, with no thickness removal specified.

Black Oxide

Black oxide is a corrosion-resistant treatment for metals, providing a matte black finish, mild rust protection, and improved wear resistance.

Powder Coating

Applicable to metals, offering matte, gloss, or textured finishes with customizable colors. Thickness removed ranges from 0.05mm to 0.15mm.

As Machined

This finish retains visible tool marks and is suitable for both metals and plastics. There is no specific thickness removed in this finish.

Brushing

Brushing produces a satin texture on parts, offering a smooth, uniform finish while concealing minor flaws.

Electroless Nickel Plating

Electroless Nickel Plating provides a uniform, corrosion-resistant finish on metals, with excellent hardness and wear resistance.

Chromate Conversion Coating

This finish can appear smooth or matte, often with a clear or slight yellow tint. A very thin layer (0.25–1 micrometer) is removed.

E-Coating

This finish, suitable for metals, can be matte or gloss, with black as the most common color.

Painting

Available for metals and plastics, this finish can be matte, gloss, or textured, with color matching possible.

Heat Treatment

Heat treatment enhances metal properties such as hardness, strength, and toughness through controlled heating and cooling processes.

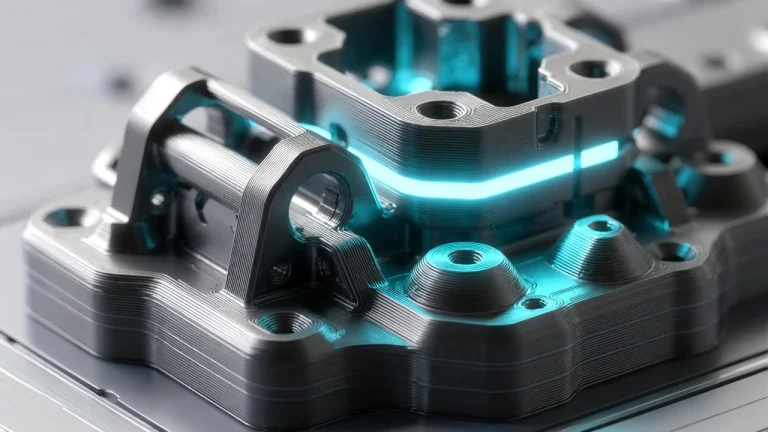

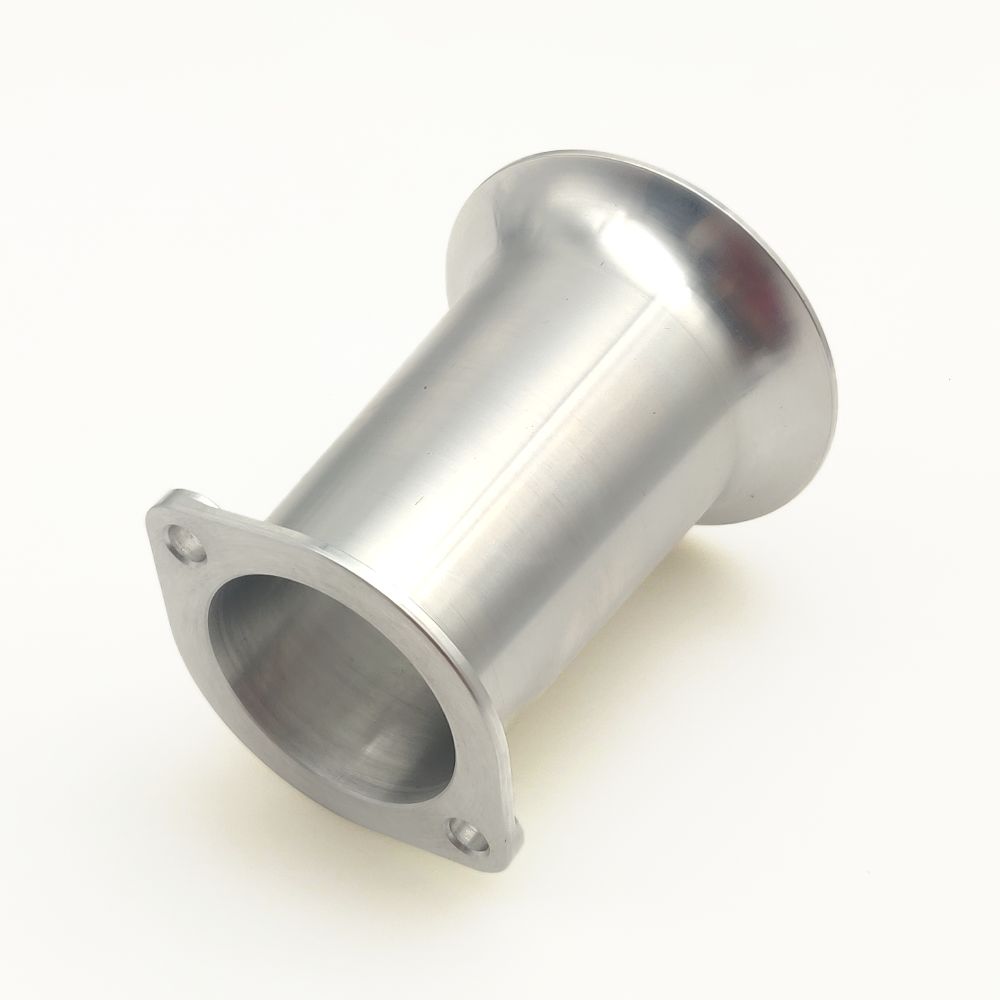

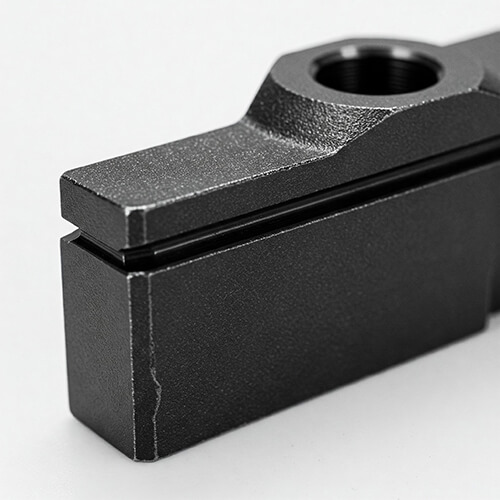

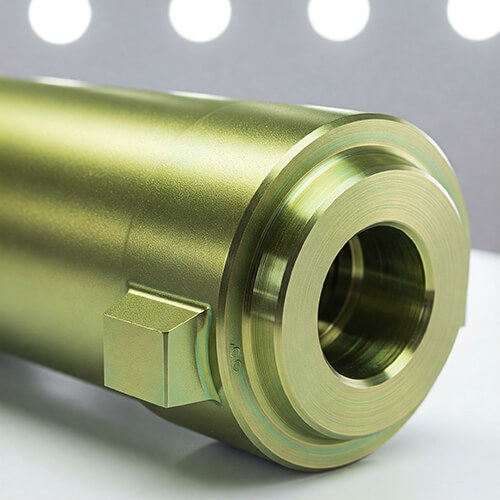

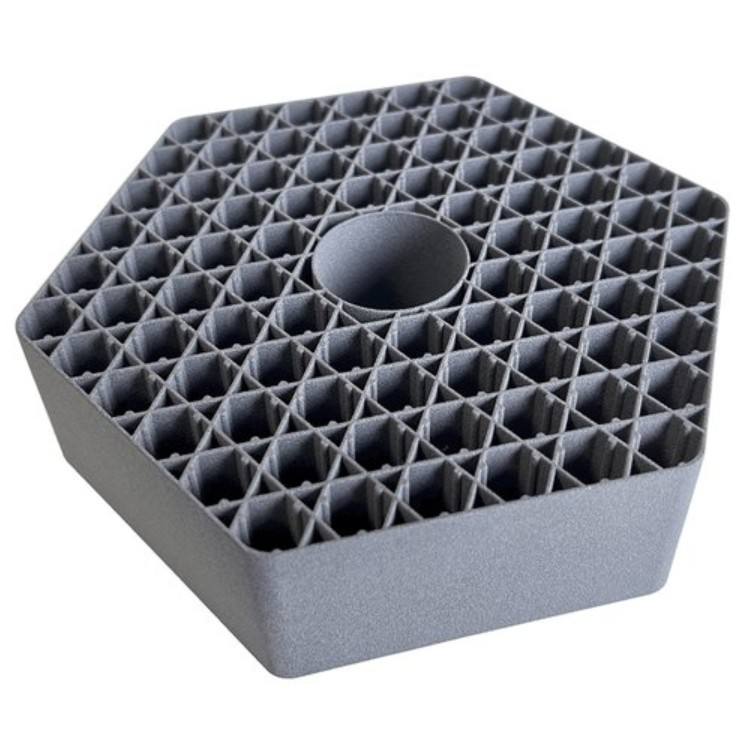

Gallery of Custom CNC Turning Parts

Following shows precision turning prototypes and parts from our esteemed customers.

CNC Turning Overview

What is CNC turning?

CNC turning is an ideal device for cutting symmetrical cylindrical or spherical parts. Typically, a lathe rotates the workpiece on a vertical or horizontal axis, while a fixed forming tool moves around the workpiece on a straight or curved path.

What is the principle of CNC turning?

CNC turning allows for a variety of operations such as face, threading, knurling, drilling, boring, reaming and taper turning. It works by loading the raw material into the lathe spindle tray after creating the G code. When the spindle rotates, the chuck holds the workpiece in place. Once the spindle reaches speed, the cutting tool makes contact with the workpiece, gradually removing the material until the desired geometry is formed.

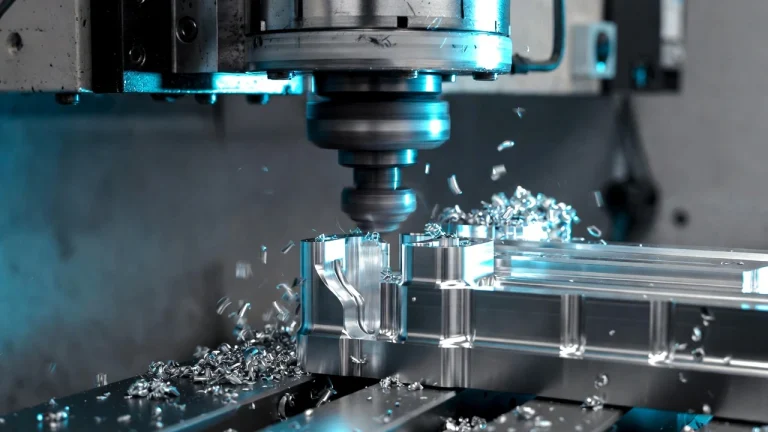

What is the difference between CNC turning and milling?

The main difference between CNC turning and CNC milling lies in the relative movement of the machine and raw materials during the machining process. In CNC milling, the material is fixed in position and the cutting tool rotates around the material. In CNC turning, the tool remains in the same position while the material rotates at high speed to form a precise shape.

Other differences include:

- Tool types: single point tools are used for turning, and multi-point tools are used for milling.

- Applicability: Milling is more suitable for flat and irregular surfaces, while turning is suitable for cylindrical or conical surfaces.

- Cutting method: turning continuous cutting, with the tool continuously in contact with the workpiece;

- Milling intermittent cutting, where the tool continuously engages and disengages from the material.

- Chip type: Milling produces discontinuous chips, while turning can produce discontinuous, continuous, and fragmented chips.

About CNC Turning FAQ

Using the latest CNC machine tools, Boona can produce high-precision turning parts in as little as 3 days.

Our CNC turning equipment and technology allow for high-precision machining, typically achieving an accuracy of 0.01 millimeters. We ensure that the machined parts meet the precise requirements of the customer.

Yes, we have an experienced technical team and advanced programming techniques that can handle various complex shaped turning parts, including inner and outer contours, holes, grooves, and various concave and convex features.

Essential CNC Machining Resources for Engineers

Latest news, trends and manufacturing design tips for precision cnc machining.