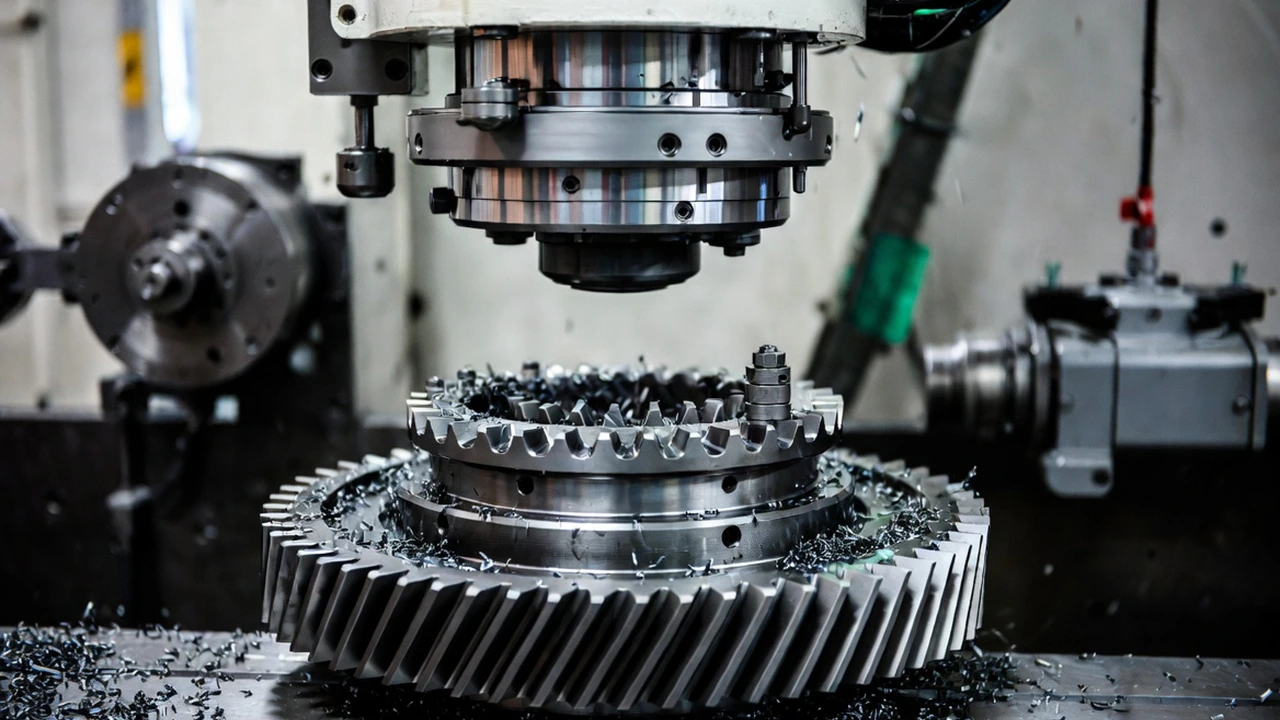

Modern industries—from EVs to robotics—depend on gears that deliver flawless motion, low noise, and maximum efficiency. As tolerances become increasingly demanding, traditional cutting and hobbing alone can no longer meet the requirements for small-batch, high-precision gears.

This is where 5-axis CNC machining excels.

And in China, Boona Prototypes has become a trusted partner for rapid, high-accuracy gear production with 3-Day No-MOQ prototyping.

Why Precision Gear Machining Matters

Gears are mission-critical components in:

-

Electric vehicles

-

Drones & robotics

-

Industrial automation machinery

-

Aerospace

-

Medical devices

Performance directly depends on gear profile accuracy, surface finish, and structural strength. Even a 5–10 µm deviation can cause:

-

Increased noise

-

Faster wear

-

Lower transmission efficiency

-

Heat buildup and failure over time

With today’s high-speed systems, precision is non-negotiable.

What Is 5-Axis CNC Gear Machining?

5-axis CNC machining enables the cutting tool to move across:

-

X / Y / Z linear axes

-

A / B rotational axes

This simultaneous movement allows:

-

Machining complex gear profiles in one setup

-

Higher accuracy due to fewer re-fixtures

-

Superior surface finish

Axis Comparison

| CNC Type | Movement | Suitable for Gears | Limitations |

|---|---|---|---|

| 3-Axis | X, Y, Z | Simple spur gears | Poor for angles or internal forms |

| 4-Axis | + rotation | Helical gears | Needs repositioning |

| 5-Axis | + dual rotation | All gear types (helical, bevel, worm, internal) | Best for precision |

Gear Types Machined with 5-Axis CNC

| Gear Type | Complexity | Machinability | Applications |

|---|---|---|---|

| Spur | Low | Easy | EV motors, robotics |

| Helical | Medium | Excellent | Quiet transmission systems |

| Bevel | High | Excellent | Automotive steering & drivetrains |

| Worm | High | Good | Precision reducers |

| Internal Ring Gears | Very High | Excellent with 5-axis | Planetary gearboxes |

Why 5-Axis CNC Is Ideal for High-Precision Gears

Ultra-Tight Tolerances

Boona achieves:

-

±0.005–0.01 mm tolerance

-

AGMA 10–12 gear accuracy

-

Minimal backlash

Superior Surface Finish

5-axis interpolation reduces tool marks.

-

Ra 0.4–1.6 µm finish

-

Lower operational noise

-

Higher efficiency (up to 98% transmission)

Complex Geometry in One Setup

Perfect for:

-

Undercuts

-

Multi-angle teeth

-

Micro-gears for drones

Less Tool Wear

Thanks to smooth toolpaths and continuous angles.

5-Axis Gear Machining Workflow at Boona Prototypes

CAD/CAM Modeling

Boona uses advanced CAM systems to generate involute profiles, chamfers, and root radii.

Material Options

| Material | Hardness (HRC) | Applications | Notes |

|---|---|---|---|

| 20CrMnTi | 58–62 | Automotive gears | Best for carburizing |

| 4140 Steel | 28–32 | Heavy loads | Strong & affordable |

| Brass | — | Low noise small gears | Great machinability |

| Aluminum | — | Drones, lightweight | Fast cutting speed |

Boona’s material list:

👉 https://www.boona-prototypes.com/cnc-machining/

Machining Processes

-

5-axis rough milling

-

5-axis finishing

-

Hobbing or shaping (if required)

-

Deburring

-

Micro-polishing

Heat Treatment Options

| Process | Case Depth | Benefit |

|---|---|---|

| Carburizing | 0.8–1.2 mm | High wear resistance |

| Nitriding | 0.3–0.6 mm | Low distortion |

| Induction Hardening | Variable | Strong tooth surface |

Inspection & QA

-

CMM gear tooth scanning

-

Profile accuracy measurement

-

Concentricity & runout testing

-

AGMA / DIN compliance

Boona inspection info:

👉 https://www.boona-prototypes.com/rapid-prototyping/

Gear Performance with Boona 5-Axis CNC

| Parameter | Capability |

|---|---|

| Accuracy | AGMA 10–12 |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.8 µm |

| Runout | ≤ 0.01 mm |

| Noise Reduction | Up to 25% lower |

Cost Factors in Gear CNC Machining

What Affects Pricing?

-

Material grade

-

Gear diameter + module

-

Heat treatment

-

Surface finishing

-

Tooling life

-

Cutting time

Typical Prototype Pricing Example

| Gear Type | Material | Qty | Lead Time | Cost (USD) |

|---|---|---|---|---|

| Small Spur Gear | Aluminum | 5 pcs | 3 days | $95–$160 |

| Helical Gear | Steel | 10 pcs | 5 days | $180–$280 |

| Bevel Gear | 4140 | 5 pcs | 6 days | $260–$350 |

Boona offers No MOQ and 3-Day Prototype Delivery.

(Internal link:

https://www.boona-prototypes.com/ )

Boona Prototypes: China’s Fastest 5-Axis Gear Machining Service

Why Companies Choose Boona

-

✔ 3-Day turnaround

-

✔ No minimum order

-

✔ High-precision 5-axis machining

-

✔ Professional material sourcing

-

✔ Full QC reports

-

✔ Global delivery

Industries served:

-

Electric Vehicles

-

Industrial Automation

-

Robotics

-

UAV (Drones)

-

Medical Devices

Request a custom quote:

👉 https://www.boona-prototypes.com/contact-us/

Conclusion

5-axis CNC machining is the most advanced method for producing high-precision gears with exceptional accuracy and surface quality. For companies needing fast turnaround, tight tolerances, and prototype-to-production support, Boona Prototypes stands out as a leading supplier in China.

Boona combines advanced 5-axis machining, world-class QC, and ultra-fast prototyping—helping engineers bring gear designs to life with unmatched precision and speed.

FAQs

What makes 5-axis CNC machining ideal for gear manufacturing?

5-axis CNC enables multi-angle tool movement, precise tooth geometry, and consistent accuracy down to ±0.005 mm, making it perfect for complex gears.

Can 5-axis CNC replace traditional gear hobbing?

Not completely. CNC machining is ideal for prototyping, small batches, and custom geometries, while hobbing remains more efficient for high-volume production.

What types of gears can be made with 5-axis CNC machining?

Spur gears, helical gears, bevel gears, worm gears, spline shafts, internal gears, and custom non-standard gears.

How accurate are 5-axis CNC machined gears?

Precision typically reaches ISO 7–8, and with optimized machining strategies, can achieve ISO 5–6 for high-performance applications.

What materials work best for CNC-machined gears?

Common choices include:

-

Aluminum 6061/7075

-

Stainless Steel 304/316/17-4PH

-

Alloy Steel 4140/4340

-

Brass & Bronze

-

Engineering Plastics (POM, Nylon, PEEK)

How does CNC gear machining improve durability?

CNC ensures consistent tooth profile, perfect pitch spacing, and proper surface finish—reducing wear, friction, and operational noise.

Is CNC gear machining cost-effective?

For prototypes and small batches, CNC is more cost-efficient because it eliminates custom cutters and long setup times.

How can I ensure gear machining quality when outsourcing to China?

Request:

-

CMM reports

-

Material certifications

-

Surface roughness test results

-

Gear inspection charts (AGMA/ISO standards)

-

Trial fit testing

A professional supplier like Boona Prototypes provides these by default.

Can Boona Prototypes handle tight tolerances for gears?

Yes. Boona offers ±0.005 mm tolerances, 5-axis machining, and full inspection — ideal for robotics, EVs, and transmission systems.

What finishing options are available for CNC-machined gears?

-

Anodizing

-

Black oxide

-

Heat treatment

-

Passivation

-

Hard anodizing

-

Zinc/nickel plating