In the world of drones, strength and lightness must coexist in perfect harmony.

For DJI, the global leader in drone innovation, this balance is achieved through CNC-machined aluminum components — the backbone of every airframe, arm, and housing that takes flight.

Each DJI drone is a masterpiece of precision machining and structural engineering, designed to endure wind, vibration, and impact — all while maintaining lightweight efficiency for extended flight times.

The Engineering Challenge: Strong, Light, and Efficient

Drone structures must handle enormous mechanical stresses — including motor vibration, wind turbulence, and landing impact — without deformation.

Aluminum CNC components play a critical role in achieving that balance:

-

Lightweight yet rigid

-

Excellent thermal management

-

Corrosion-resistant and durable

-

High fatigue strength

| Design Goal | Mechanical Requirement | Material Solution |

|---|---|---|

| Lightweight | Density < 3 g/cm³ | Aluminum 6061 / 7075 |

| Structural Strength | Tensile > 250 MPa | Aerospace-grade alloys |

| Heat Dissipation | Thermal > 150 W/m·K | CNC Aluminum |

| Precision Fit | Tolerance ±0.01 mm | CNC machining |

💡 Strong enough to lift a camera. Light enough to fly for hours.

Inside DJI CNC Machining Workflow

DJI uses CNC machining not only for prototyping but also for mass-production of structural drone components.

This process ensures precision, repeatability, and mechanical reliability.

Step-by-Step Workflow:

-

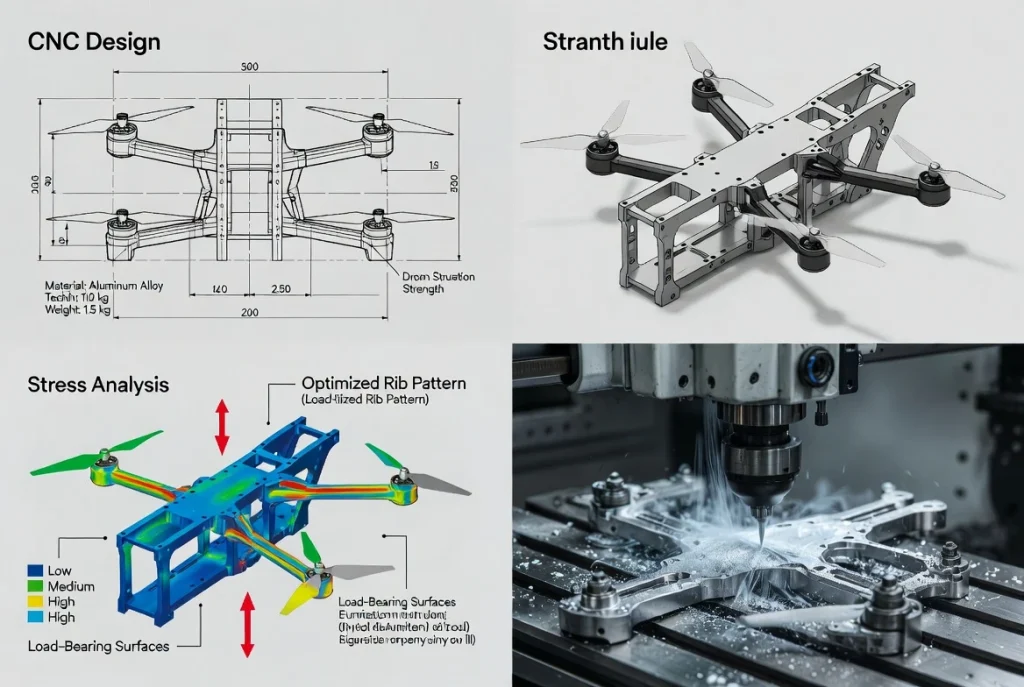

CAD Design & Simulation – Engineers perform FEA (Finite Element Analysis) for strength and weight.

-

CNC Machining – Parts are milled using 3-axis and 5-axis machining centers.

-

Surface Finishing – Anodizing, sandblasting, and hard coating for corrosion protection.

-

Assembly & Quality Control – Every part is inspected and fitted to micron-level accuracy.

| Component | CNC Process | Material | Tolerance (mm) |

|---|---|---|---|

| Arm Frame | 5-axis milling | 7075-T6 | ±0.01 |

| Motor Mount | Turning + threading | 6061-T6 | ±0.005 |

| Gimbal Housing | Pocket milling | 6061-T6 | ±0.008 |

| Camera Bracket | Multi-axis machining | 6061-T6 | ±0.01 |

🧩 Over 60% of DJI drone structural parts are CNC machined for precision fit and strength.

Why CNC Aluminum Is Perfect for Drones

CNC aluminum machining combines aerospace-grade performance with mass-producible precision — ideal for drone engineering.

| Property | Aluminum 6061 | Aluminum 7075 |

|---|---|---|

| Density (g/cm³) | 2.70 | 2.81 |

| Tensile Strength (MPa) | 310 | 570 |

| Yield Strength (MPa) | 276 | 503 |

| Thermal Conductivity (W/m·K) | 151 | 130 |

| Fatigue Resistance | High | Very High |

| Machinability | 90% | 80% |

💬 DJI uses 6061 for frames and housings, while 7075 is used for structural arms and load-bearing joints.

CNC Design Strategies for Structural Strength

DJI engineers apply advanced topology optimization and generative design to make parts both strong and lightweight.

Key CNC Design Techniques:

-

Topology optimization: Removes excess material while maintaining rigidity.

-

Internal ribbing: Strengthens parts without added weight.

-

Chamfered edges: Reduces stress concentration.

-

Thin-wall milling (<1.5 mm): Preserves stiffness and lowers total mass.

| Optimization Type | Function | Weight Reduction (%) |

|---|---|---|

| Ribbed Geometry | Structural reinforcement | 25% |

| Material Hollowing | Reduce non-critical mass | 30% |

| Curved Fillets | Prevent fatigue cracks | 10% |

| Adaptive Wall Thickness | Balance stress points | 15% |

⚙️ Average DJI part weight reduced by up to 40% while maintaining full strength.

Surface Finishing for Strength and Durability

Once machined, each aluminum component undergoes finishing to protect against oxidation, vibration, and impact.

| Finishing Type | Purpose | Visual Effect |

|---|---|---|

| Anodizing (Type II) | Corrosion resistance | Satin or matte |

| Hard Anodizing (Type III) | Surface hardness + wear protection | Dark matte |

| Bead Blasting | Texture consistency | Premium feel |

| Laser Engraving | Component marking | Precision finish |

💡 DJI signature gray and matte-black finishes come from anodizing and bead blasting, enhancing both durability and aesthetics.

Quality Control: Where Precision Meets Performance

Every CNC part undergoes multi-step verification to ensure flight safety and performance consistency.

| Inspection Method | Accuracy | Purpose |

|---|---|---|

| CMM Measurement | ±0.003 mm | Dimensional check |

| Optical Scanner | ±0.005 mm | Surface geometry validation |

| Surface Roughness Test | Ra 0.8 µm | Aerodynamic consistency |

| Vibration Test | 10,000 RPM | Flight stress validation |

📏 Each DJI part must pass both mechanical and aerodynamic tests before assembly.

Case Study: DJI Mavic 3 Structural Frame

The DJI Mavic 3 uses CNC aluminum for its primary frame and arm joints.

| Specification | Before Optimization | After CNC Optimization |

|---|---|---|

| Weight (Arm Assembly) | 420 g | 285 g |

| Max Load Capacity | 3.1 kg | 4.2 kg |

| Thermal Dissipation | 100 W/m·K | 150 W/m·K |

| Structural Rigidity | 100% | +48% Improvement |

⚙️ CNC machining reduced component weight by 32% while improving strength and cooling efficiency.

Sustainability and Material Efficiency

DJI implements closed-loop recycling in its CNC production line:

-

95% of aluminum chips are collected and remelted for reuse.

-

Advanced CAM toolpaths minimize waste by 20%.

-

Coolant filtration systems reduce fluid waste by 30%.

♻️ DJI CNC operations align with ISO 14001 environmental standards.

The Performance Edge: Why CNC Precision Matters

| Advantage | Impact on Flight |

|---|---|

| High stiffness-to-weight ratio | Longer flight duration |

| Precise part alignment | Stable gimbal and camera movement |

| Thermal conductivity | Better battery & motor cooling |

| Structural balance | Reduced vibration and noise |

💬 CNC precision is not just manufacturing excellence — it’s flight performance you can feel.

Conclusion

CNC aluminum machining gives DJI drones the perfect fusion of lightweight strength, precision, and durability.

Each component — from the arm frame to the gimbal mount — reflects micron-level craftsmanship that defines DJI global engineering reputation.

🚀 Through CNC innovation, DJI continues to push the boundaries of flight — stronger, lighter, and more efficient than ever.

FAQs

Why does DJI use CNC aluminum parts instead of plastic or carbon fiber?

DJI chooses CNC aluminum because it offers the ideal balance of strength, precision, and heat dissipation.

Unlike molded plastics, CNC aluminum maintains dimensional stability under vibration and temperature changes, and it’s fully recyclable — making it both durable and sustainable.

What types of aluminum alloys are used in DJI drones?

DJI primarily uses Aluminum 6061-T6 and 7075-T6:

-

6061-T6 → great for frames and housings (lightweight, easy to machine).

-

7075-T6 → used for structural arms and load-bearing joints (aerospace-grade strength).

| Property | 6061-T6 | 7075-T6 |

|---|---|---|

| Tensile Strength (MPa) | 310 | 570 |

| Yield Strength (MPa) | 276 | 503 |

| Density (g/cm³) | 2.70 | 2.81 |

How does CNC machining improve drone strength and stability?

CNC machining provides micron-level accuracy, ensuring all drone components fit perfectly and stay vibration-free during flight.

This high precision enhances aerodynamic stability, motor balance, and camera performance, especially in high-speed or windy conditions.

What is the typical machining tolerance of DJI aluminum parts?

DJI CNC parts are produced with extremely tight tolerances:

| Parameter | Value |

|---|---|

| Dimensional Tolerance | ±0.005–0.01 mm |

| Surface Roughness | Ra 0.8 µm |

| Repeatability | 99.95% |

Such accuracy ensures consistent flight performance and smooth assembly across thousands of units.

How does DJI reduce weight without losing strength?

DJI applies topology optimization and generative design to remove unnecessary material while preserving rigidity.

CNC machining enables complex internal ribbing and thin-wall structures (<1.5 mm), reducing weight by up to 40% without sacrificing strength.

Why is aluminum ideal for heat management in drones?

Aluminum’s thermal conductivity (130–150 W/m·K) dissipates motor and battery heat efficiently.

This helps maintain motor lifespan and battery performance, especially during long flights or in hot environments.

What surface finishing methods does DJI use on CNC aluminum parts?

DJI applies a combination of protective and aesthetic finishes:

-

Anodizing (Type II) – corrosion resistance and color uniformity

-

Hard Anodizing (Type III) – increased surface hardness

-

Bead Blasting – smooth, matte texture

-

Laser Etching – precision marking

These finishes not only protect but also give DJI drones their premium metallic look.

How does DJI test the strength of CNC aluminum components?

Each CNC aluminum part undergoes multi-stage quality control, including:

-

CMM (Coordinate Measuring Machine) dimensional checks

-

High-frequency vibration tests up to 10,000 RPM

-

Load-bearing and drop-impact testing

-

Thermal expansion analysis

This ensures every frame and arm maintains integrity under flight stress.

Is CNC machining environmentally sustainable for drone production?

Yes — CNC aluminum machining aligns with DJI sustainability goals:

-

95% of aluminum chips are recycled.

-

Toolpath optimization reduces waste by 20%.

-

Coolant filtration and reuse lower environmental impact.

♻️ DJI CNC workflow meets ISO 14001 environmental standards.

How does CNC aluminum improve flight performance?

CNC machining enhances flight by ensuring:

-

Perfect structural alignment (less vibration)

-

Better motor mounting precision (smoother operation)

-

Lightweight frames (longer battery life)

-

Improved rigidity (stability in strong winds)

Result: longer flight time, steadier video, and improved safety.

What are DJI quality control standards for CNC parts?

DJI enforces strict multi-axis inspection protocols:

| Inspection Method | Accuracy | Purpose |

|---|---|---|

| CMM Measurement | ±0.003 mm | Dimensional accuracy |

| Optical Scan | ±0.005 mm | Surface deviation check |

| Surface Finish Test | Ra 0.8 µm | Aerodynamic finish |

| Vibration Test | 10,000 RPM | Flight load test |

What lessons can manufacturers learn from DJI CNC approach?

-

Integrate CNC machining early in product development.

-

Use topology-optimized CAD designs for lightweight durability.

-

Prioritize precision alignment for vibration control.

-

Recycle aluminum scrap to achieve sustainability goals.

💡 DJI formula for success: precision + lightweight design = better performance.