In recent years, rapid prototyping has emerged as a transformative force in manufacturing, especially within high-innovation fields like the drone industry. Traditionally, developing new drone designs required expensive tooling and long lead times. Now, with the help of advanced prototyping technologies such as 3D printing, CNC machining, and vacuum casting, companies can accelerate development and significantly reduce costs. As a leading provider in this space, Boona Prototypes is at the forefront of this shift, delivering fast, high-quality prototyping services tailored for emerging drone applications.

I. Accelerating Research and Development

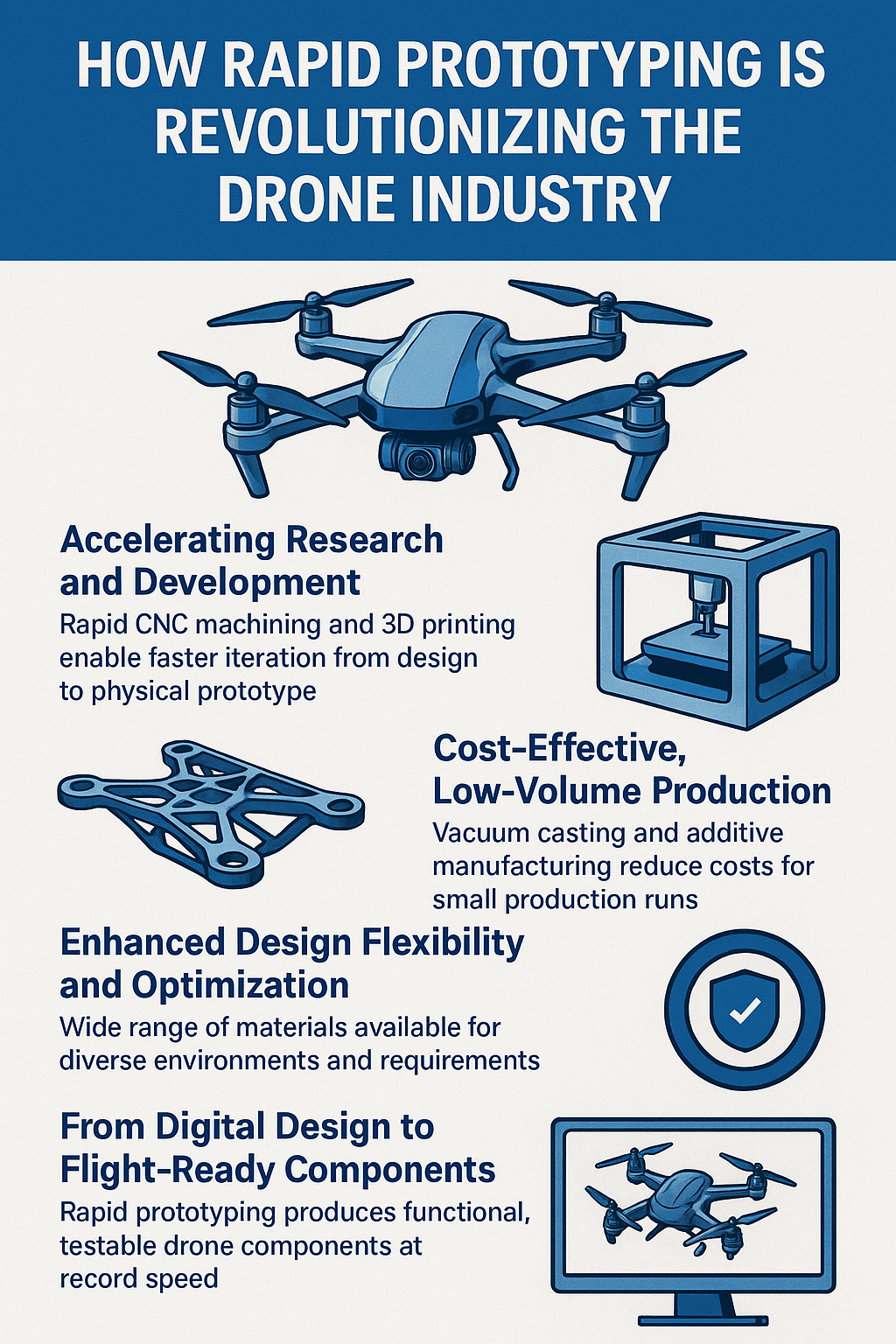

Time is critical in drone development, especially when adapting to rapidly changing market demands or regulatory requirements. With rapid CNC machining services from Boona, developers can go from digital design to physical prototype in days rather than weeks. This acceleration allows teams to test aerodynamics, structural integrity, and component fit earlier in the product lifecycle—minimizing costly errors downstream.

II. Cost-Effective, Low-Volume Production

Rapid prototyping also enables cost-effective low-volume production, which is ideal for startups or companies testing new drone models. Traditional manufacturing methods require expensive molds, making small production runs impractical. With solutions like urethane vacuum casting, Boona enables low-cost duplication of drone parts using silicone molds and high-strength resins. This method is particularly beneficial for creating drone housings and aerodynamic components at a fraction of the cost of injection molding.

III. Enhanced Design Flexibility and Optimization

Weight is a critical factor in drone performance. Additive manufacturing and CNC milling allow designers to create lightweight, optimized structures that were previously impossible with subtractive manufacturing. Using Boona’s custom CNC milling services, drone frames can be machined with precise tolerances and complex geometries, optimizing strength-to-weight ratios without compromising structural integrity.

IV. Material Innovation for Specialized Applications

Drones are used in various environments—from desert surveillance to coastal mapping—so the choice of materials matters. Boona offers a wide selection of materials suitable for drone applications, including aluminum alloys, ABS, nylon, carbon fiber-reinforced polymers, and more. Their 3D printing capabilities support advanced thermoplastics like PA12 and TPU, which are perfect for shock-resistant parts like landing gear or protective casings.

V. Tailored Solutions Across Industries

Whether you’re building drones for agriculture, aerial photography, logistics, or defense, customization is essential. Boona’s ability to deliver bespoke drone components, such as camera mounts or sensor housings, helps manufacturers tailor drones to specific missions. With services ranging from sheet metal prototyping to pressure die casting, developers can create parts suited for both lightweight consumer drones and robust industrial UAVs.

VI. From Digital Design to Flight-Ready Components

Boona’s integrated workflow—spanning CAD design review, engineering validation, and full-scale production—supports faster turnaround without sacrificing quality. Their team of experts evaluates each prototype for manufacturability, performance, and cost, ensuring clients receive components that meet the strict standards required for drone flight.

By combining digital design with rapid fabrication, companies can create functional drone prototypes that are ready for flight testing in record time. This iterative process enables engineers to quickly refine airframes, propeller configurations, and payload systems before committing to large-scale production.

VII. A Glimpse Into the Future

As drone technology continues to evolve, so will the materials and processes that support it. With the rise of smart materials, generative design, and on-demand manufacturing, rapid prototyping will continue to push the limits of drone innovation. Boona’s commitment to cutting-edge solutions positions them as a strategic partner for drone developers seeking agility, precision, and reliability.

Conclusion

From speeding up product development to enabling innovative design, rapid prototyping is revolutionizing how drones are conceived, built, and deployed. Boona Prototypes exemplifies this transformation, offering state-of-the-art prototyping services that empower creators across the drone industry. Whether you’re a startup engineer or part of a large defense contractor, Boona’s comprehensive capabilities can help you bring your next-generation drone to life—faster, lighter, and smarter than ever before.

FAQs

1. What is rapid prototyping and how does it benefit drone development?

Rapid prototyping is a product development technique that quickly transforms digital designs into physical models using methods like 3D printing, CNC machining, and vacuum casting. For the drone industry, this allows faster testing of parts, reduces costs, and shortens time to market. Learn more about Boona prototyping services.

2. Which prototyping method is best for creating drone parts?

It depends on the application. CNC machining is great for strong, functional components; 3D printing is ideal for fast concept models or lightweight structures; and vacuum casting works well for low-volume production. Explore options on Boona 3D printing page or CNC services page.

3. Can rapid prototyping be used for flight-ready drone components?

Yes, many materials used in rapid prototyping—such as nylon, carbon fiber composites, and aluminum alloys—are durable and lightweight enough for actual flight components. Boona offers high-quality materials suitable for both prototypes and end-use parts.

4. How fast can I get a prototype for a new drone design?

With companies like Boona, lead times can be as fast as 1–3 days depending on part complexity and material. Their instant quotation system helps streamline the process for faster turnaround.

5. Is it possible to produce small batches of drone parts without high tooling costs?

Absolutely. Boona offers vacuum casting and low-volume CNC machining, which eliminates the need for injection molds, making it cost-effective to produce limited batches.

6. What types of drone parts can be prototyped?

Nearly all types:

-

Airframes and arms

-

Propeller guards and motor mounts

-

Payload enclosures

-

Sensor housings

-

Battery compartments

Boona supports custom fabrication of complex parts via their sheet metal and CNC services.

7. How does rapid prototyping help reduce drone weight?

Through design optimization (e.g., lattice structures) and use of lightweight materials, prototyping enables precise control over drone weight—crucial for flight time and payload capacity. This is often achieved using advanced CNC milling techniques.

8. Can I use the same prototype for flight testing and mass production?

In some cases, yes—especially if the prototype is made from production-grade materials. Boona provides engineering-grade plastics and metals that are suitable for both functional testing and pilot production.

9. How accurate are 3D-printed or CNC-machined drone parts?

With Boona’s precision equipment, parts can be produced to tolerances as tight as ±0.01mm, making them reliable for complex assemblies and performance testing.

10. Does Boona provide design support or only manufacturing?

Boona offers full-spectrum support—from DFM (Design for Manufacturability) guidance to post-processing, surface finishing, and logistics. Their team ensures your drone prototype is ready for both testing and presentation. Contact them through their support page.