In the fast-evolving electric vehicle (EV) industry, speed of innovation defines success.

Tesla — a pioneer of electric mobility — has built its dominance not only through design or software but through its relentless rapid prototyping capability.

Behind Tesla futuristic vehicles lies a foundation of CNC (Computer Numerical Control) machining, enabling engineers to transform 3D CAD designs into real, testable parts within hours.

Let’s explore how Tesla uses CNC prototyping to shorten R&D cycles, accelerate EV innovation, and set new industry standards.

Why CNC Prototyping Is Vital for Tesla R&D

In Tesla design workflow, every component undergoes multiple iterations — from concept sketch to production-ready part.

Rapid prototyping allows Tesla to physically test aerodynamic, structural, and thermal performance long before committing to expensive tooling.

| Prototyping Method | Accuracy | Material Strength | Best Use Case |

|---|---|---|---|

| CNC Machining | ★★★★★ | Production-grade | Functional testing |

| 3D Printing | ★★☆☆☆ | Moderate | Visual models |

| Casting | ★★★☆☆ | High | Low-volume production |

💡 Tesla engineers estimate that CNC prototypes cut design validation time by up to 60% compared to traditional processes.

Inside Tesla CNC Prototyping Workflow

Tesla engineering workflow combines digital simulation with physical validation through CNC machining.

Step 1 — CAD Design & Digital Simulation

-

3D modeling with CATIA, Siemens NX, and SolidWorks.

-

Digital twins simulate stress, airflow, and thermal behavior.

-

Automated geometry optimization for manufacturability.

Step 2 — CNC Machining & Precision Manufacturing

-

Multi-axis machining centers in Fremont, Giga Texas, and Giga Berlin.

-

Machined aluminum, titanium, and polymer prototypes within hours.

-

Real-time CMM measurement ensures ±0.01 mm consistency.

Step 3 — Assembly & Testing

-

CNC parts are assembled into subsystems (motors, battery modules, chassis).

-

Functional tests: vibration, fatigue, and heat dissipation.

-

Design feedback loop triggers next-generation iterations.

| Phase | Lead Time | Tolerance | Goal |

|---|---|---|---|

| CAD & Simulation | 6–8 hours | Virtual | Design validation |

| CNC Machining | 12–24 hours | ±0.01 mm | Functional prototype |

| Testing & Feedback | 12–24 hours | ±0.02 mm | Performance evaluation |

🕒 Total turnaround time per prototype: 48–72 hours.

CNC Technologies Driving Tesla Innovation

| Technology | Application | Benefit |

|---|---|---|

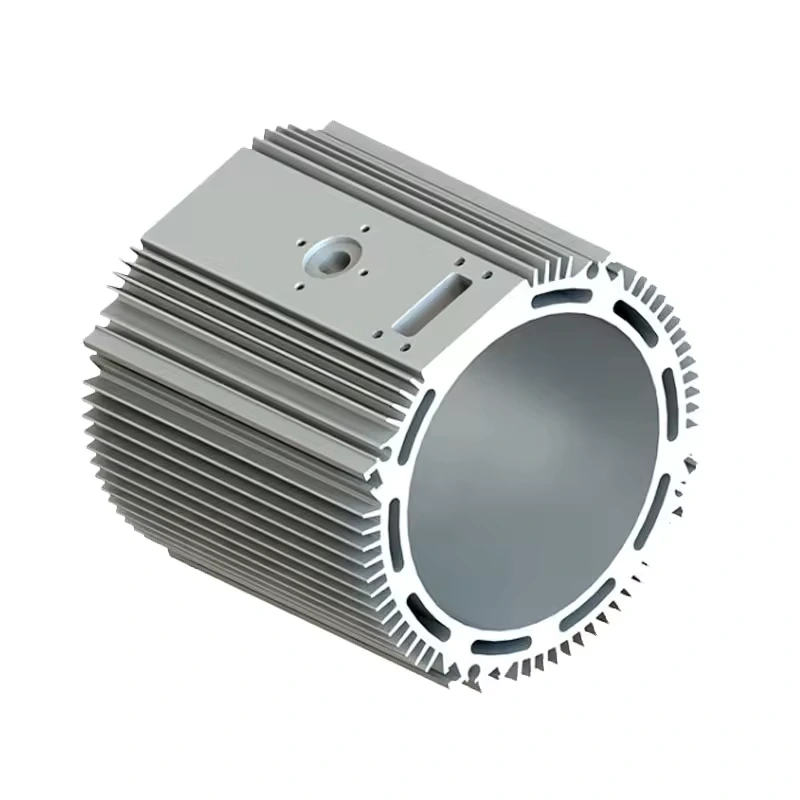

| 5-Axis CNC Machining | Motor housings, mold components | Complex surfaces, precise contours |

| CNC Turning Centers | Shafts, bushings, fasteners | High-speed cylindrical precision |

| CNC EDM (Electrical Discharge Machining) | Battery cooling plates, thin-wall features | Micro-tolerance accuracy |

| CMM Inspection Systems | Dimensional validation | Sub-0.01 mm accuracy |

📏 Tesla in-house machining tolerances are often tighter than ±0.01 mm for metal parts.

Materials Used in Tesla CNC Prototypes

Tesla selects CNC materials based on functionality, weight, and thermal conductivity — balancing strength and sustainability.

| Material | Application | Reason for Use |

|---|---|---|

| Aluminum 6061 / 7075 | Motor housings, suspension parts | Lightweight, corrosion-resistant |

| Stainless Steel 304 / 316 | Battery casings, structural supports | Strength and corrosion resistance |

| Titanium | Drivetrain shafts, brackets | Superior strength-to-weight ratio |

| Engineering Plastics (POM, Nylon, PEI) | Dashboard, insulation parts | Cost-effective and durable |

💡 Tesla uses recyclable aluminum alloys to align with its sustainability mission.

How CNC Machining Accelerates Tesla EV Innovation Cycle

Tesla CNC prototyping provides three major advantages:

-

Rapid Iteration – Design, test, and improve within days, not weeks.

-

In-House Capability – Reduced outsourcing delays and IP risks.

-

Scalability – CNC prototypes easily transition into pilot production.

| Metric | Before CNC Integration | After CNC Integration |

|---|---|---|

| Prototype lead time | 10–14 days | 2–3 days |

| Design iteration cycles | 4–5 per month | 12+ per month |

| Validation success rate | 70% | 92% |

🚀 Tesla development teams can now test and iterate up to 3× faster than traditional automakers.

Real-World CNC Components at Tesla

| Component | CNC Process | Key Function |

|---|---|---|

| Motor Housing (Model 3) | 5-axis milling | Lightweight + precise fit |

| Battery Cooling Plate | CNC routing + drilling | Heat management efficiency |

| Suspension Arm | Turning + milling | Strength and weight optimization |

| Dashboard Trim (Interior) | Plastic CNC machining | Aesthetic and fit validation |

📊 Each CNC prototype undergoes dynamic load and thermal cycling tests before design approval.

Tesla Prototype Validation Loop

Tesla R&D teams continuously optimize designs using a data-driven validation loop:

-

Machine prototype →

-

Measure using CMM →

-

Perform stress & fatigue tests →

-

Feed back results into CAD →

-

Iterate next version.

| Validation Type | Tool / Method | Target Tolerance |

|---|---|---|

| Dimensional | CMM / 3D Scanner | ±0.01 mm |

| Thermal Performance | Infrared sensors | ±1°C |

| Vibration Test | 6-axis shaker | ±0.02 mm deflection |

| Fitment Accuracy | Assembly gauge | ±0.05 mm |

🧠 Each design cycle improves part performance by up to 15%.

CNC Machining vs. Tesla Gigacasting: The Perfect Balance

Tesla Gigacasting technology revolutionized large-scale production, but CNC machining remains critical for pre-production and prototype testing.

| Process | Used In | Advantage |

|---|---|---|

| CNC Machining | Pre-production | Fast iteration, precision testing |

| Gigacasting | Mass production | Cost efficiency, scalability |

| Hybrid Use | Transition stage | Prototype validation before die-cast tooling |

⚙️ CNC prototyping helps verify designs before investing in Gigacasting molds costing $3–5 million.

Lessons from Tesla for Global Manufacturers

-

Integrate design and manufacturing teams early.

-

Use CNC and simulation together for digital + physical validation.

-

Build in-house prototyping labs for faster iteration.

-

Adopt data feedback loops to continuously optimize designs.

💬 Tesla approach has reshaped how industries approach prototyping — transforming CNC machining into a strategic innovation accelerator.

Conclusion

Tesla success isn’t just electric — it’s mechanical precision in motion.

By combining advanced CNC prototyping, multi-axis technology, and intelligent validation, Tesla compresses R&D cycles from weeks to days, staying years ahead of its competitors.

As the EV industry evolves, one truth remains:

⚙️ Rapid CNC prototyping is the engine behind faster innovation.

FAQs

What is CNC prototyping and why is it important for Tesla?

CNC (Computer Numerical Control) prototyping is a precision manufacturing process that uses automated machines to cut parts from solid materials.

Tesla relies on CNC machining to produce functional, high-precision metal and plastic prototypes that can be tested under real-world conditions before entering production.

How fast can Tesla make a CNC prototype?

Tesla internal machining facilities can produce and validate functional CNC prototypes within 48–72 hours, depending on the part’s complexity and material type.

This rapid turnaround allows engineers to iterate designs multiple times per week, accelerating product development.

Which CNC technologies does Tesla use in its prototyping process?

Tesla employs a combination of advanced technologies, including:

-

5-axis CNC machining for complex aluminum and steel parts

-

CNC turning centers for shafts and cylindrical components

-

CNC EDM for precision cuts in battery and motor parts

-

CMM inspection for dimensional accuracy to ±0.01 mm

These tools ensure both speed and repeatable precision across all prototypes.

What materials does Tesla use for CNC prototypes?

Tesla uses both metal and engineering plastics, including:

-

Aluminum 6061 / 7075 — lightweight and corrosion-resistant

-

Stainless steel 304 / 316 — strong and heat-resistant

-

Titanium alloys — used for high-strength structural components

-

POM, Nylon, and PEI (Ultem) — used for interior and non-conductive parts

How does CNC machining improve Tesla innovation cycle?

CNC machining enables faster design feedback loops.

By going from CAD to part in days, Tesla can:

-

Reduce R&D lead time by up to 60%

-

Validate designs under real mechanical loads

-

Improve quality and manufacturability early

This results in quicker product launches and continuous performance improvements.

What are examples of Tesla components made using CNC prototyping?

Common CNC-machined parts include:

-

Motor housings for EV drivetrains

-

Battery cooling plates for temperature management

-

Suspension arms and brackets

-

Dashboard and interior fitment prototypes

These parts are first CNC-machined, then tested before final tooling investment.

How does CNC machining compare to Tesla Gigacasting process?

| Aspect | CNC Machining | Gigacasting |

|---|---|---|

| Stage | Pre-production | Mass production |

| Speed | 48–72 hours | Minutes per part |

| Flexibility | High | Low |

| Purpose | Design validation | Full-scale manufacturing |

CNC machining verifies part geometry and fit before Tesla commits to expensive Gigacasting molds (costing $3–5 million each).

Does Tesla use in-house or outsourced CNC prototyping?

Tesla operates in-house CNC prototyping labs in Fremont, Giga Texas, and Giga Berlin.

This internal capability ensures:

-

Faster turnaround

-

Full IP protection

-

Seamless integration between design and production teams

For certain specialized materials, Tesla also collaborates with trusted CNC suppliers for overflow or precision tooling.

How accurate are Tesla CNC prototypes?

Tesla CNC parts typically achieve:

| Parameter | Value |

|---|---|

| Dimensional tolerance | ±0.01 mm |

| Surface roughness | Ra 0.8–1.6 µm |

| Repeatability | 99.9% |

| Validation Method | CMM + 3D scanning |

Such precision ensures parts can move directly into low-volume or pilot production stages without redesign.

What lessons can other manufacturers learn from Tesla CNC process?

-

Integrate CAD and CNC workflows early for shorter R&D cycles.

-

Maintain in-house machining for confidentiality and rapid feedback.

-

Use CNC to validate designs before large-scale tooling.

-

Combine CNC + data analysis for continuous improvement.

💡 In essence, Tesla treats CNC machining not as a service — but as a strategic innovation tool.

Is CNC prototyping sustainable for EV development?

Yes. CNC machining produces less waste, uses recyclable materials like aluminum, and allows part reuse during iteration.

This fits Tesla mission for sustainable, resource-efficient manufacturing.

What software supports Tesla CNC workflow?

Tesla uses CAD/CAM systems such as:

-

CATIA for complex body structure modeling

-

Siemens NX for machining path generation

-

SolidWorks & Mastercam for component-level simulation

These integrate directly with Tesla CNC centers, allowing automated programming and digital twin simulation.