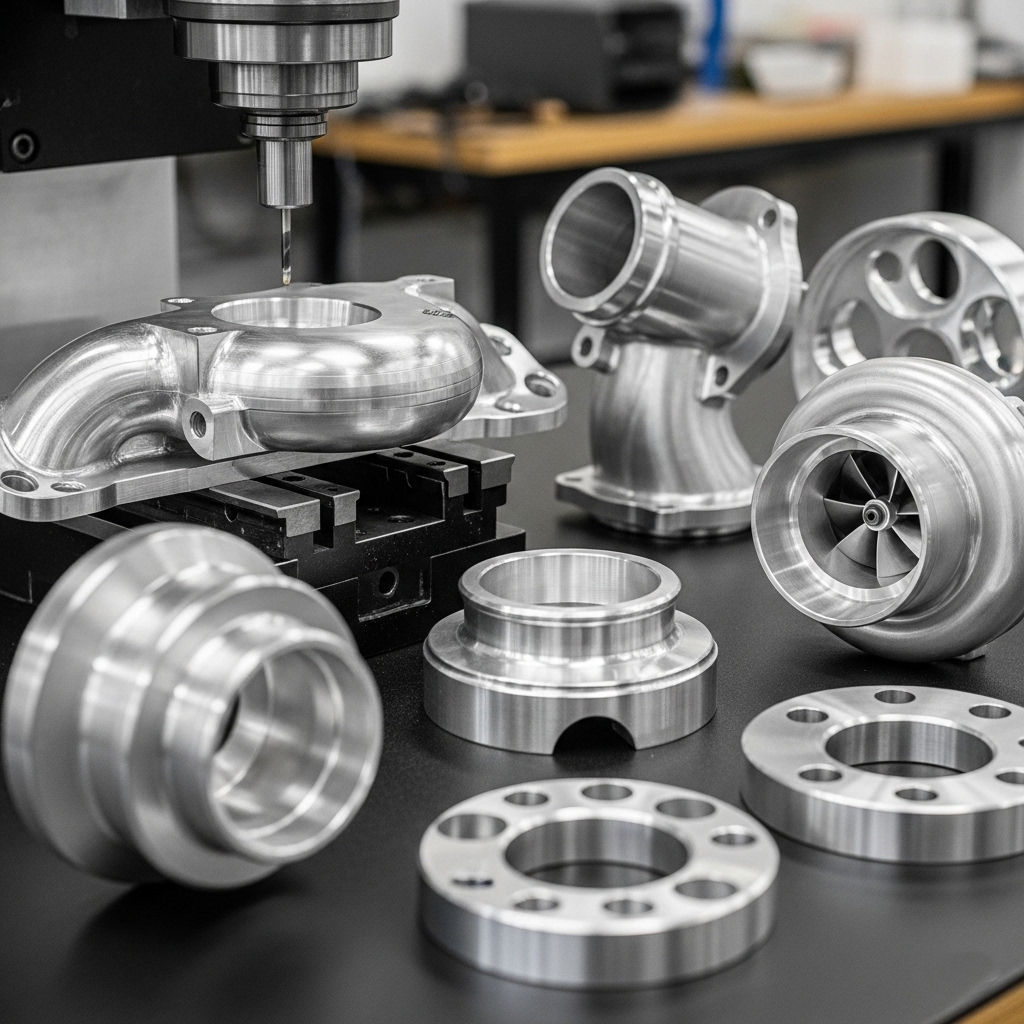

In the fast-paced automotive industry, custom parts often need to be manufactured quickly without compromising quality or performance. Whether you’re restoring a classic car, building a high-performance vehicle, or prototyping a new component, CNC machining is the go-to solution for rapid, precise, and repeatable custom part production.

This guide will show you how to efficiently go from concept to finished product—often in just a few days—with the help of expert CNC partners like Boona Prototypes.

I. Start with a Precise CAD Design

Your journey begins with a 3D CAD model of the custom part you need. Make sure your design:

-

Uses standard hole sizes and radii.

-

Avoids overly thin walls (see table below).

-

Includes only essential tight tolerances.

Boona Prototypes accepts major CAD formats (e.g., STP, STEP, X_T) and provides free DFM (Design for Manufacturability) feedback, reducing costly revisions.

Recommended Minimum Wall Thickness

| Material Type | Recommended Min. Thickness |

|---|---|

| Aluminum | 0.5 – 0.8 mm |

| Steel | 0.8 – 1.0 mm |

| ABS Plastic | 1.0 – 1.5 mm |

| Nylon | 1.2 – 1.5 mm |

For more tips on design compatibility and CNC specs, visit Boona CNC Machining Service page.

II. Choose Materials and Surface Finishes

Material selection plays a key role in performance and aesthetics. Common choices for car parts include:

| Material | Characteristics | Use Cases |

|---|---|---|

| Aluminum 6061 | Lightweight, corrosion-resistant | Brackets, housings, mounts |

| Stainless 304 | Strong, wear- and rust-resistant | Exhaust components, fasteners |

| ABS | Cost-effective, impact-resistant plastic | Interior parts, mounts |

| PEEK | High heat and chemical resistance | Under-the-hood and electronic parts |

Boona offers dozens of material options and supports finishes such as anodizing, black oxide, bead blasting, and powder coating. Learn more at Boona surface finishing solutions.

III. Select a Rapid CNC Machining Provider

Turnaround time can make or break your project. Boona Prototypes specializes in rapid prototyping and low-volume production, with delivery in as fast as 3–7 days depending on complexity.

Why Boona?

-

Instant quoting via CAD upload

-

No minimum order quantity

-

ISO 9001 certified

-

3-, 4-, and 5-axis machining capabilities

-

Dedicated support for automotive applications

Explore Boona CNC capabilities for complex parts, tight tolerances, and fast delivery.

IV. Understand CNC Machining Capabilities

Boona supports the following processes:

| Process | Machine Axis | Best For |

|---|---|---|

| 3-Axis Milling | X, Y, Z | Flat parts, pockets, holes |

| 4-Axis Machining | X, Y, Z + A | Parts with features around cylinders |

| 5-Axis Machining | X, Y, Z + 2 | Complex geometries, single setup |

| CNC Turning | 2-Axis | Shafts, bushings, round parts |

Using 5-axis CNC machining significantly reduces the number of setups and improves accuracy—ideal for complex automotive components. Boona provides expert support on choosing the right process for your needs.

V. Quality Control and Finishing

Even under tight deadlines, quality remains essential. Boona Prototypes adheres to strict quality protocols, including:

-

CMM (Coordinate Measuring Machine) inspections

-

First Article Inspection (FAI) reports

-

Material certification

-

Salt-spray corrosion tests (on request)

After machining, your parts can be polished, coated, or engraved with a logo. Check the full list of post-processing and inspection services for more information.

VI. Delivery in Days, Not Weeks

Boona’s streamlined workflow—from DFM feedback to automated CAM programming—helps reduce total lead time. For simpler aluminum parts, production can begin in less than 24 hours after final approval.

Typical Lead Times

| Part Complexity | Lead Time |

|---|---|

| Simple 3-axis part | 3–5 business days |

| Moderate part w/ finishing | 5–7 business days |

| Complex 5-axis or multi-material | 7–10 business days |

Global delivery is supported via DHL, FedEx, and UPS, ensuring quick arrival of your custom components.

Conclusion

Getting custom car parts made fast doesn’t require compromise. With CNC machining and the right partner, you can produce high-precision components tailored to your exact needs—on a tight deadline.

Whether it’s a single prototype or a short production run, Boona Prototypes provides everything you need—from material selection and design consultation to machining, inspection, and final delivery.

Get your quote today and turn your custom car part ideas into reality—in as little as 3 days.

FAQs

1. How fast can I get custom car parts made with CNC machining?

With a rapid prototyping partner like Boona Prototypes, you can receive your CNC-machined car parts in as little as 3 to 7 business days, depending on the complexity and material. Simple aluminum parts may be produced within 48–72 hours after final design approval.

2. What materials are best for custom automotive parts?

Common materials include:

-

Aluminum 6061 or 7075 (lightweight, corrosion-resistant)

-

Stainless steel 304 or 316 (strong, wear-resistant)

-

ABS and Nylon (for interior and low-load components)

Boona offers a wide material selection for CNC machining, including metals and high-performance plastics.

3. Can I get just one part made, or do I need to order in bulk?

Yes, CNC machining is perfect for one-off custom parts or small batches. Boona Prototypes supports no minimum order quantity, ideal for prototyping, testing, or limited production runs.

4. How do I start the process of making a custom car part?

-

Create a 3D CAD model of your part.

-

Upload it to Boona’s platform.

-

Receive a fast quote and free DFM feedback.

-

Approve the design and material.

-

Begin production and delivery.

Explore the step-by-step process here.

5. What CNC services does Boona offer for automotive applications?

Boona provides:

-

3-axis, 4-axis, and 5-axis CNC machining

-

Turning and milling

-

Finishing options (anodizing, polishing, coating)

-

Quality control (CMM, FAI, ISO 9001)

Visit Boona CNC machining capabilities for technical details.

6. What is the difference between 3-axis and 5-axis CNC machining for car parts?

-

3-axis: Great for flat and simple parts.

-

5-axis: Ideal for complex, multi-surface components like brackets, housings, or engine parts. It allows for single-setup machining, which saves time and improves accuracy.

Boona Prototypes utilizes advanced 5-axis machines for high-precision car components.

7. Can I choose a surface finish for my custom parts?

Absolutely. Boona offers multiple finishing options including:

-

Anodizing (various colors)

-

Powder coating

-

Bead blasting

-

Black oxide

-

Laser engraving

Finishes improve appearance and durability. Learn more about available surface treatments here.

8. Will I receive quality inspection reports with my parts?

Yes. Boona provides:

-

First Article Inspection (FAI)

-

CMM reports

-

Material certificates

-

Salt spray and other test results (on request)

This ensures each part meets your specifications. See more about Boona quality control process.