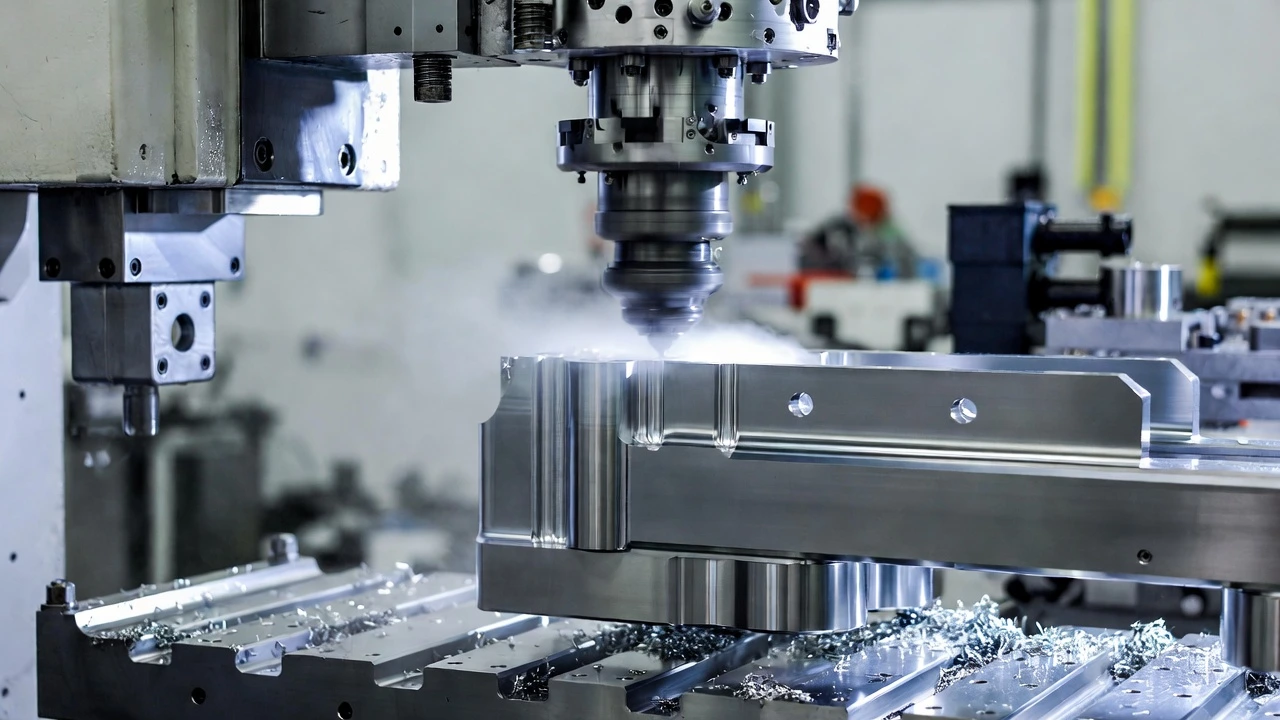

Let’s be honest: machining stainless steel isn’t exactly a walk in the park. As a manufacturing engineer, I’ve seen firsthand how this tough, gummy material can chew through cutting tools, chatter during deep pocketing, and warp if the thermal management isn’t dialed in perfectly.

But when your project requires components that can survive a corrosive marine environment, withstand extreme heat, or meet stringent medical hygiene standards, there’s simply no substitute. If you’re actively looking for stainless steel CNC machining services for custom metal parts, you already know the stakes are high. Getting it right means balancing tight tolerances, the correct material grade, and a budget that doesn’t blow up your bottom line.

Here is a practical, shop-floor look at what it takes to manufacture high-quality stainless components, and what you should look for in a manufacturing partner.

Picking the Right Grade (Because They Aren’t All Created Equal)

One of the most common mistakes we see in incoming CAD files is a generic callout for “Stainless Steel.” Specifying the exact alloy is critical because the machinability and end-use performance vary wildly. Here is a quick breakdown of what we cut most often on the shop floor:

| Material Grade | The Engineer’s Take | Typical Yield Strength | Where We See It Used |

| 304 / 304L | The absolute workhorse. It offers a great balance of corrosion resistance and strength. It’s not the easiest to machine, but it’s highly versatile. | 215 MPa | Food processing equipment, architectural brackets, general-purpose enclosures. |

| 316 / 316L | The upgrade. Thanks to added molybdenum, this grade fights off chlorides (like salt water) and pitting far better than 304. | 205 MPa | Marine hardware, surgical instruments, chemical processing manifolds. |

| 303 | The machinist’s best friend. The added sulfur makes chips break away cleanly, allowing for faster feed rates and lower costs on high-volume runs. | 240 MPa | Custom fasteners, precision shafts, and high-volume aerospace fittings. |

| 17-4 PH | The heavy hitter. This precipitation-hardening grade is incredibly tough and is usually heat-treated after rough machining to hit peak strength. | 1,000+ MPa | Turbine blades, defense components, heavy-duty industrial valves. |

Hitting the Tolerances That Matter

When you’re dealing with precision CNC machining stainless steel parts, the numbers have to mean something in reality, not just on a drawing.

Standard “good” machining will get you within ±0.01 mm (±0.0004 inches). But when we are setting up a 5-axis mill or a Swiss lathe for critical aerospace or medical components, we often have to hold much tighter tolerances on specific bearing fits or sealing surfaces. The secret isn’t just having an expensive machine; it’s about rigid workholding, managing tool deflection, and keeping the spindle temperature consistent.

If you are just testing a new design, the last thing you want is a shop forcing you into a 500-piece run. Finding a partner that handles low-volume manufacturing with zero minimum order quantity (NO MOQ) allows you to order a single prototype, validate the fit, and iterate without wasting capital.

The Realities of Surface Finishing

A part fresh off the CNC mill will have visible tool marks. For an internal bracket, an “as-machined” finish (usually around Ra 1.6 μm) is perfectly fine and keeps costs down. However, stainless is often chosen for its aesthetics or sanitary properties, which means post-processing is a must.

Depending on the application, you might need bead blasting for a uniform, non-reflective matte look, or electropolishing to strip away microscopic burrs and leave a sterile, mirror-like finish. Don’t treat finishing as an afterthought—make sure your supplier has robust surface finishing options under one roof so you aren’t dealing with multiple vendors and shifting lead times.

Why Experience Matters

Since 2004, the team at Boona Prototypes has been refining the art of cutting tough metals. We know that work-hardening is the enemy of a good stainless part. If your feed rate drops or the tool rubs instead of cutting, the material instantly hardens, snapping end mills and ruining the workpiece. Overcoming this requires high-pressure coolant, premium coated-carbide tooling, and operators who actually understand the physics of the cut.

Whether you need a handful of custom stainless steel prototypes delivered in a week, or you are looking to scale up and source affordable stainless steel prototypes in China to keep your project under budget, the right engineering support makes all the difference. We always run a free Design for Manufacturability (DFM) check before the first chip is ever cut, ensuring your design is optimized for the machine, not just the screen.

Ready to see how your design translates to the real world? Send over your STEP files and let’s get a conversation started.

FAQs

Why are my stainless steel parts so much more expensive to machine than aluminum?

It rarely comes down to just the cost of the raw bar stock. Stainless steel is notoriously tough and prone to work-hardening. If the cutting tool dwells for even a second, the surface hardens, destroying the tool. Because of this, we have to run our CNC machines at much slower speeds and feeds compared to cutting 6061 aluminum. More machine time and higher tool wear directly translate to a higher part cost.

What tolerances can you realistically hold on a stainless part?

On a standard run, hitting ±0.01 mm (±0.0004 inches) is our baseline. However, as a manufacturing engineer, I always tell clients: just because we can hold a ±0.005 mm tolerance doesn’t mean you should put it on every dimension of your drawing. Extremely tight tolerances require specialized fixturing, brand-new end mills for finishing passes, and constant CMM inspection. Only tolerance the critical mating surfaces; leave the rest standard to keep your costs down.

304 vs. 316: Which one do I actually need?

I see people over-specifying 316 all the time. Here is the short version: if your part is going underwater, exposed to salt spray, or used in a harsh chemical or medical environment, pay the premium for 316. It has added molybdenum that specifically fights chloride pitting. If your part is just for general indoor use, food processing, or architectural hardware, 304 is more than enough and will save you money.

Can I get just one or two prototypes, or do you need a production-sized order?

You don’t need a massive order. We run a strict “No MOQ” (Minimum Order Quantity) policy. Whether you need a single custom bracket to prove out a new assembly design, or you’re ready to scale into the thousands, the process is the same. Getting a rapid prototype in your hands is the best way to catch design flaws early.

How do you prevent thin-walled stainless parts from warping?

Stainless steel holds a lot of internal stress, especially if it’s cold-rolled stock. When we start milling away material, those stresses release, and the part wants to warp like a potato chip. To fight this, we use a strategy of roughing the part out entirely, letting it rest (or heat-treating it to relieve stress), and then taking very light, fast finishing passes. Designing your part with wall thicknesses above 1mm also goes a long way in preventing vibration and deflection during the cut.

Do I need a special surface finish?

If the part is purely functional and hidden inside an assembly, our standard “as-machined” finish is perfectly fine. But if you are building something for the medical, food, or semiconductor industries, you will likely need passivation or electropolishing. Passivation removes free iron from the surface so it won’t rust, while electropolishing physically strips away a microscopic layer of metal to leave an ultra-smooth, sterile, and highly reflective surface.

Since we opened our doors in 2004, we’ve helped countless designers navigate the headaches of custom metal fabrication. If you’ve got a tricky stainless part on your desk right now, send over your CAD files for a free DFM review, and we can apply a 10% discount to your upcoming prototype run to help get the project off the ground.