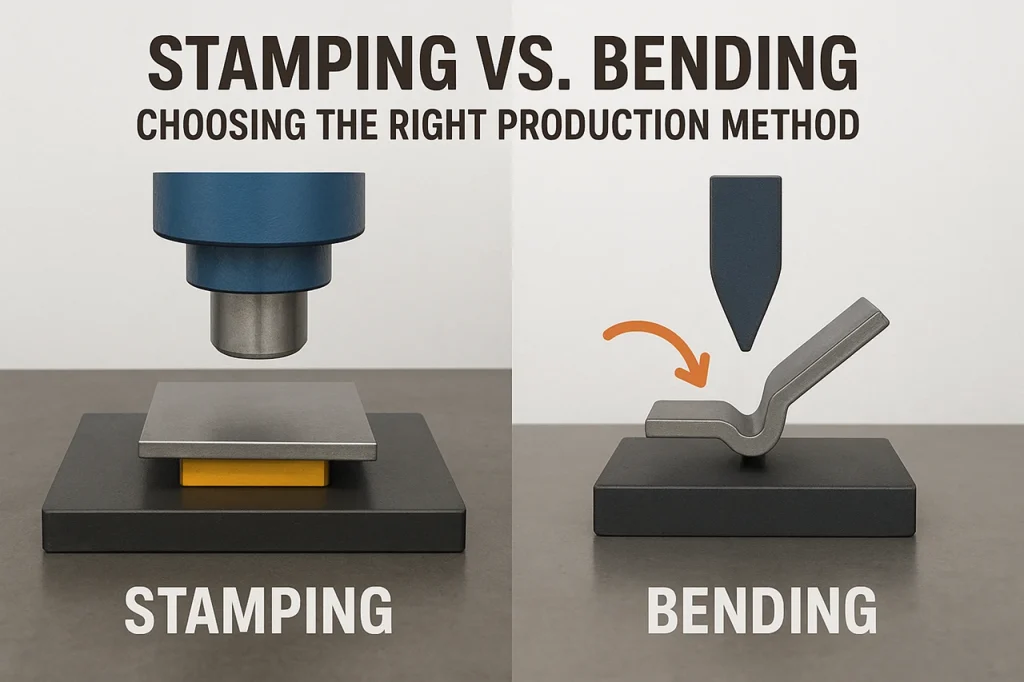

In modern manufacturing, the ability to shape sheet metal efficiently and precisely is critical to product quality and cost. Two of the most widely used processes — metal stamping and metal bending — play essential roles in industries such as automotive, aerospace, and consumer electronics.

While both methods form metal into functional parts, their production approaches, cost structures, and suitability vary significantly. Choosing the right method can impact not only production efficiency but also final product performance.

This article explores the differences between stamping and bending, compares their advantages, limitations, and ideal use cases, and helps you determine the best solution for your project.

Understanding Metal Stamping

1. Definition and Process

Metal stamping is a cold-forming process that uses a press and die set to shape flat metal sheets into specific forms. Depending on the design, stamping may involve operations such as:

-

Blanking: Cutting out flat shapes from sheet metal.

-

Punching: Creating holes or slots in a sheet.

-

Coining or Embossing: Producing raised or recessed features.

-

Flanging: Bending the metal edge for stiffness or assembly.

Typical stamping equipment:

-

Mechanical presses (30–1000 tons capacity)

-

Hydraulic presses (up to 2000 tons)

-

Progressive dies for high-speed production

2. Materials and Thickness Range

| Material Type | Typical Thickness Range (mm) | Applications |

|---|---|---|

| Stainless Steel | 0.2 – 3.0 | Automotive panels, appliances |

| Aluminum | 0.5 – 2.5 | Electronics, aerospace |

| Copper | 0.2 – 1.5 | Electrical connectors |

| Carbon Steel | 0.5 – 4.0 | Structural and mechanical parts |

3. Advantages of Stamping

-

High productivity: Up to 100–600 parts per minute on automated lines.

-

Excellent repeatability: Dimensional accuracy typically within ±0.05 mm.

-

Cost efficiency: Lower per-part cost in large volumes.

-

Complex shapes possible: Multi-stage dies allow forming, cutting, and punching in one operation.

4. Limitations of Stamping

-

High initial tooling costs (often $5,000–$50,000 depending on die complexity).

-

Design changes require expensive die modifications.

-

Generates more material waste, especially in blanking and punching.

Understanding Metal Bending

1. Definition and Process

Metal bending involves deforming sheet metal along a straight axis to achieve an angle or curve, without removing material.

Common bending operations include:

-

V-bending: Using a punch and V-die to create a specific angle.

-

Air bending: Controlling bend depth and angle by partial die contact.

-

Roll bending: Producing large-radius curves with rollers.

Equipment used:

-

CNC press brakes (20–500 tons capacity)

-

Folding machines

-

3-roll or 4-roll bending machines

2. Materials and Thickness Range

| Material Type | Typical Thickness Range (mm) | Bend Radius (Minimum) |

|---|---|---|

| Mild Steel | 0.5 – 6.0 | 1 × thickness |

| Aluminum | 0.8 – 4.0 | 1.5 × thickness |

| Stainless Steel | 0.5 – 4.0 | 1.5–2 × thickness |

| Titanium | 0.5 – 3.0 | 2 × thickness |

3. Advantages of Bending

-

Low tooling cost: Standard dies can be reused across projects.

-

High flexibility: Suitable for design modifications and custom runs.

-

Minimal material waste.

-

Ideal for small and medium production batches or prototypes.

4. Limitations of Bending

-

Slower than stamping — typically 10–20 bends per minute.

-

Limited to simple linear geometries.

-

Accuracy depends on setup; tolerance typically ±0.1 mm.

-

Springback may affect precision, especially with high-strength alloys.

Stamping vs. Bending: Detailed Comparison

| Parameter | Stamping | Bending |

|---|---|---|

| Production Volume | High (10,000+ parts) | Low to medium (1–5,000 parts) |

| Tooling Cost | High ($5,000–$50,000) | Low ($200–$1,000) |

| Flexibility | Low | High |

| Cycle Time | 0.1–1.0 sec/part | 3–6 sec/part |

| Precision | ±0.05 mm | ±0.1 mm |

| Setup Time | Long (2–4 hours) | Short (15–30 min) |

| Material Waste | Moderate to high | Minimal |

| Ideal Materials | Thin sheets (≤3 mm) | Medium to thick sheets (≥1 mm) |

| Shape Complexity | Very high | Limited to straight bends |

| Automation Level | Fully automated | Semi or fully automated |

Applications in Industry

1. Common Uses of Stamping

-

Automotive body panels and brackets

-

Electrical connectors and motor housings

-

Smartphone and laptop enclosures

-

Appliance components (washers, microwaves, etc.)

2. Common Uses of Bending

-

Enclosures, frames, and cabinets

-

HVAC ducts and metal furniture parts

-

Custom chassis and support brackets

-

Low-volume prototypes or custom fabrication

Choosing the Right Method

Selecting between stamping and bending depends on multiple production parameters:

| Criteria | Recommended Process |

|---|---|

| High production volume | Stamping |

| Low or medium volume | Bending |

| Complex 3D shape | Stamping |

| Straight or angular parts | Bending |

| Short lead time / rapid prototyping | Bending |

| Cost per part optimization | Stamping |

| Frequent design changes | Bending |

| Thin material (<2 mm) | Stamping |

| Thick material (>3 mm) | Bending |

Example:

-

Producing 100,000 identical brackets → Stamping (lower unit cost).

-

Producing 500 custom machine panels → Bending (flexibility and faster setup).

Integration of Both Methods

In many modern fabrication workflows, stamping and bending are used together to maximize efficiency and precision.

For instance:

-

An automotive bracket may be stamped from sheet metal to achieve holes and flanges, then bent to the final mounting shape.

-

This hybrid approach reduces welding steps and maintains high geometric accuracy.

Conclusion

Both stamping and bending are essential metal forming processes, each with distinct advantages.

-

Stamping dominates mass production with high precision and complex geometries, but requires significant initial investment.

-

Bending offers flexibility, cost efficiency for small batches, and quick setup, making it ideal for prototypes and custom manufacturing.

Choosing the right process depends on your design complexity, production scale, and budget. In many cases, combining both methods delivers the best balance between efficiency and flexibility.

FAQs

What is the main difference between stamping and bending?

Stamping uses dies and presses to cut or form metal sheets into complex shapes, often in one or several steps.

Bending, on the other hand, deforms the metal along a straight axis to create angles or curves without cutting the material.

In short, stamping is used for shaping, while bending is mainly used for angular forming.

Which process is more suitable for high-volume production?

Metal stamping is better for high-volume production because it offers faster cycle times and consistent results. Once the dies are set up, thousands of parts can be produced per hour with minimal variation.

Is metal bending more cost-effective for small batches?

Yes. Bending requires simple and reusable tooling, making it more economical for low- to medium-volume production, prototypes, or custom parts where design flexibility is important.

How accurate are stamping and bending processes?

-

Stamping tolerance: typically ±0.05 mm

-

Bending tolerance: typically ±0.1 mm (depending on setup, tooling, and material)

Stamping provides higher dimensional accuracy due to fixed dies, while bending precision depends on operator skill and press brake calibration.

What types of materials can be used for stamping and bending?

Both processes work well with sheet metals such as aluminum, stainless steel, copper, carbon steel, and brass.

However, stamping is generally better for thin materials (0.2–3.0 mm), while bending is ideal for thicker sheets (1–6 mm).

Can stamping and bending be combined in one production line?

Absolutely. Many manufacturers use stamping to create holes, flanges, or contours, followed by bending to achieve the final part geometry.

This hybrid approach improves both precision and efficiency in complex assemblies.

Which process offers better design flexibility?

Bending offers greater flexibility because parts can be adjusted or redesigned quickly without creating new dies.

Stamping requires expensive die changes for any modification, making it less suitable for rapid design updates.

What are the tooling costs for each process?

-

Stamping: High — custom dies can cost from $5,000 to $50,000+ depending on complexity.

-

Bending: Low — standard press brake tools usually cost $200 to $1,000 and can be reused across projects.

Which process is faster — stamping or bending?

Stamping is significantly faster, producing up to 100–600 parts per minute in automated lines.

Bending typically forms 10–20 parts per minute, depending on part complexity and setup.

What are the common applications of each process?

-

Stamping: automotive panels, electrical housings, connectors, appliance components.

-

Bending: enclosures, frames, brackets, furniture parts, and custom prototypes.

Can both processes be automated using CNC machines?

Yes. Modern fabrication shops use CNC stamping presses and CNC press brakes for automated control, ensuring consistent quality, faster throughput, and reduced labor costs.

How do I decide between stamping and bending for my project?

Choose stamping if you need:

-

High production volume

-

Tight tolerances

-

Complex part geometry

Choose bending if you need:

-

Design flexibility

-

Quick prototyping

-

Low to medium production volume