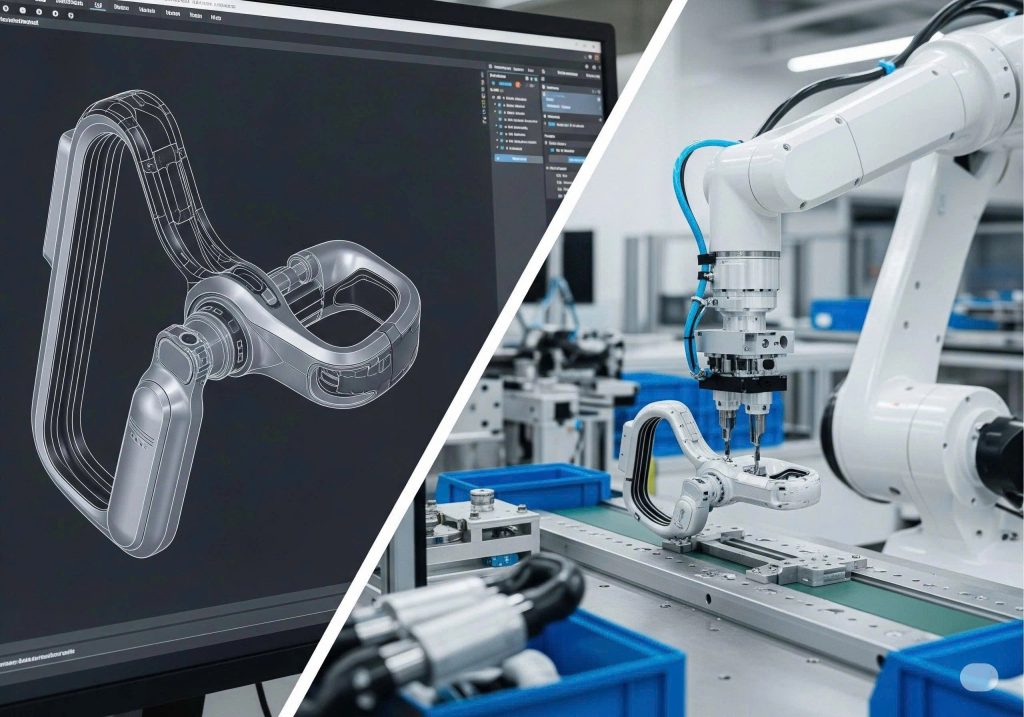

In the fast-paced medical device industry, innovation is often driven by the need for precision, safety, and regulatory compliance. However, bringing a medical device from concept to market is not only about design creativity—it is about making sure that the device can be manufactured efficiently, reliably, and at scale. This is where Design for Manufacturability (DFM) analysis plays a crucial role.

DFM ensures that product designs are optimized for real-world manufacturing processes, reducing the risk of costly redesigns and production delays. Companies like Boona Prototypes support medical innovators by integrating DFM analysis with rapid prototyping, CNC machining, injection molding, and low-volume manufacturing, ensuring smoother transitions from design to production.

I. Why DFM Matters in Medical Device Prototyping

1. Reducing Costs and Time-to-Market

Medical device companies operate under intense time-to-market pressures. Any late-stage design changes can lead to significant costs and regulatory setbacks. By conducting DFM analysis during the prototyping stage, engineers can:

-

Detect design flaws early.

-

Reduce tooling adjustments.

-

Streamline parts for lower assembly complexity.

Partnering with a provider like Boona Prototypes allows medical teams to prototype, validate, and iterate quickly, avoiding costly surprises later in production.

2. Ensuring Quality and Regulatory Compliance

Medical devices require precision and consistency to meet regulatory standards (FDA, ISO 13485, CE). DFM supports this by:

-

Minimizing dimensional variations.

-

Enabling reliable assembly methods.

-

Reducing risks of defects during mass production.

For example, when designing a catheter component, tolerances and material selection must align with both manufacturability and patient safety requirements. A robust DFM review ensures compliance is built into the product from the beginning.

3. Prototyping as a Testing Ground

Rapid prototyping provides a safe platform to test functionality, geometry, and manufacturability before full-scale production. At this stage, different technologies can be applied:

-

SLA 3D printing for fine detail and surface quality.

-

CNC machining for strength and material validation.

-

Injection molding for pre-production samples.

Boona Prototypes offers all these services, giving medical engineers the flexibility to match prototyping techniques to DFM needs.

4. Optimizing Material and Process Selection

Medical devices often require biocompatible, durable, and process-compatible materials. DFM guides material and process choices to balance performance with scalability.

Here is a comparison table of common prototyping processes and their relevance in medical device DFM:

| Process | Typical Materials | Key Advantages | DFM Considerations |

|---|---|---|---|

| CNC Machining | Metals (Aluminum, Stainless Steel, Ti) | High precision, strength, excellent tolerances | Machining complexity may raise costs |

| SLA 3D Printing | Biocompatible resins, medical-grade resins | Fine details, smooth surfaces, quick turnaround | Limited strength for load-bearing parts |

| SLS 3D Printing | Nylon, medical-grade PA | Durable, flexible, functional prototypes | Surface roughness requires finishing |

| Injection Molding | Medical-grade plastics (PC, ABS, PEEK) | Best for scaling to production, accurate samples | Requires draft angles and mold-friendly design |

By aligning material capabilities with manufacturing constraints, DFM ensures that the chosen prototype process can scale effectively into mass production.

II. Key DFM Principles in Medical Device Development

Some universal principles of DFM that medical engineers should adopt include:

-

Early DFM integration: Begin manufacturability checks at the CAD stage.

-

Part simplification: Fewer parts mean fewer assembly errors.

-

Design for Assembly (DFA): Components should fit together easily, reducing operator error.

-

Error-proofing (Poka-Yoke): Incorporate design elements that prevent incorrect use or assembly.

-

Supply chain awareness: Ensure material availability aligns with production scalability.

These principles are especially critical for medical devices, where design choices can directly affect patient outcomes.

III. How Boona Prototypes Supports DFM in Medical Device Prototyping

Boona Prototypes is a trusted partner for companies looking to accelerate medical innovation. Their services provide:

-

Comprehensive DFM reviews during the prototype phase.

-

Rapid prototyping technologies (CNC, SLA, SLS, molding) for iterative testing.

-

Low-volume manufacturing to bridge the gap between prototypes and mass production.

-

One-stop solutions that reduce the risk of delays caused by switching suppliers.

By working with Boona Prototypes, medical innovators can align product design with scalable manufacturing from day one.

Conclusion

In medical device development, DFM analysis is not optional—it is essential. By identifying manufacturability issues early, companies save time, reduce costs, and ensure compliance with strict healthcare standards. Through the use of rapid prototyping and DFM-driven design practices, medical devices can move from concept to market with greater efficiency and safety.

With an experienced partner like Boona Prototypes, medical teams can confidently turn their designs into manufacturable, regulatory-compliant, and market-ready products.

FAQs

1. What is DFM analysis in medical device prototyping?

DFM (Design for Manufacturability) analysis is the process of reviewing a device design to ensure it can be manufactured efficiently, reliably, and at scale. In medical prototyping, it helps align product design with real-world manufacturing processes like CNC machining, 3D printing, or injection molding.

2. Why is DFM important in medical device development?

DFM is critical because medical devices must meet strict safety and regulatory standards. By addressing manufacturability early, engineers reduce the risk of costly redesigns, accelerate time-to-market, and ensure consistency in quality and performance.

3. At what stage should DFM analysis be done?

DFM should be integrated as early as possible—ideally during the concept and CAD design stage. Early analysis helps avoid downstream issues such as tooling changes, assembly challenges, or supply chain bottlenecks.

4. Which prototyping methods benefit most from DFM?

All prototyping methods benefit, but particularly:

-

CNC machining (precision components, tight tolerances).

-

3D printing (SLA, SLS) (complex geometries, quick iterations).

-

Injection molding (pre-production and scaling).

DFM ensures the chosen process aligns with regulatory and production requirements.

5. How does DFM improve time-to-market for medical devices?

By identifying design flaws early, DFM reduces the number of revisions and shortens the development cycle. Rapid prototyping services like those from Boona Prototypes allow for faster iterations and validation, significantly accelerating time-to-market.

6. Can DFM help with regulatory compliance?

Yes. DFM supports regulatory compliance by ensuring design consistency, minimizing assembly errors, and maintaining tight tolerances. This reduces risks of product recalls and ensures smoother certification processes.

7. What role does material selection play in DFM for medical devices?

Material selection is central to DFM. Medical devices require biocompatible, durable, and scalable materials. DFM ensures chosen materials not only meet performance and safety needs but also align with the manufacturing process for mass production.

8. How does Boona Prototypes support DFM in medical prototyping?

Boona Prototypes provides DFM reviews, rapid prototyping, and low-volume manufacturing services. Their expertise ensures that designs transition smoothly from prototype to production without costly redesigns or delays.