In today’s fast-paced product development cycles, rapid prototyping is essential for transforming ideas into tangible products quickly. One of the most effective methods for building high-precision prototypes is CNC machining—a subtractive manufacturing process known for speed, accuracy, and material versatility.

In this article, we’ll explain what CNC machining is, how it fits into the rapid prototyping workflow, and why companies like Boona Prototypes rely on it to accelerate innovation.

I. What Is CNC Machining?

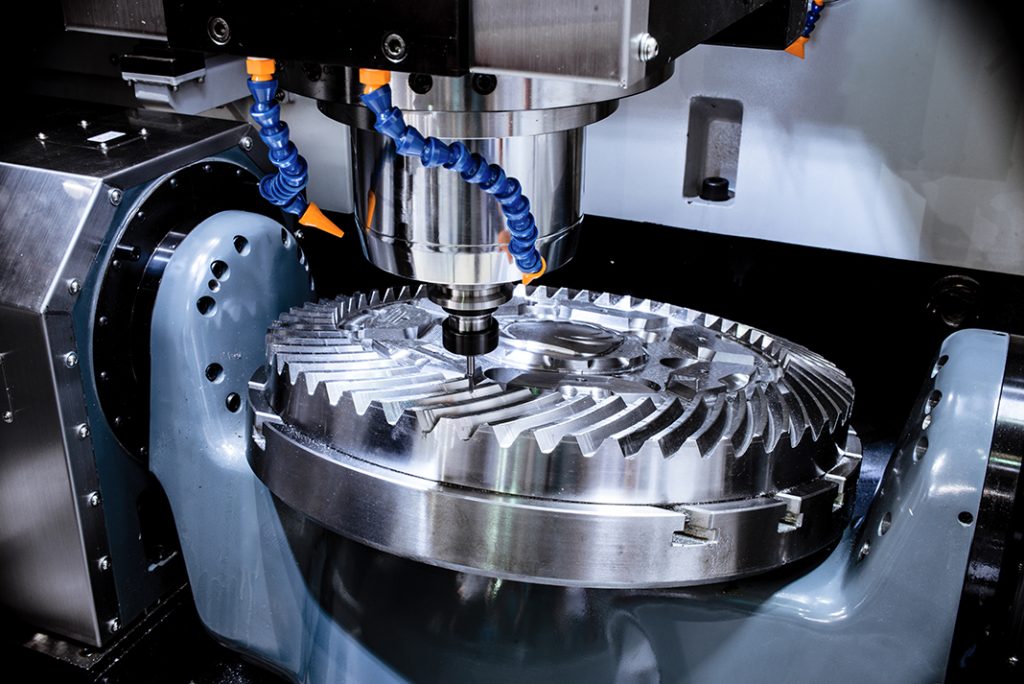

CNC (Computer Numerical Control) machining is a digital manufacturing process where machines such as mills, lathes, and routers cut away material from a solid block (metal or plastic) to create a part. Unlike 3D printing, which builds layer by layer, CNC is a subtractive process—which means it removes material to shape the final product.

CNC machines are programmed using CAD/CAM software, enabling manufacturers to achieve highly complex geometries with tolerances as tight as ±0.01 mm. This level of precision makes CNC machining ideal for creating functional prototypes that mimic production parts.

II. CNC Machining Workflow for Rapid Prototyping

Here’s how a typical CNC prototyping process unfolds:

-

Design: Create a 3D CAD model of the part.

-

Programming: Generate toolpaths using CAM software.

-

Material Selection: Choose from metals or plastics (see material options below).

-

Machining: Fabricate the part using milling, turning, or EDM.

-

Post-Processing: Surface finishing, deburring, or coating.

III. Comparison Table: CNC Machining for Rapid Prototyping

| Parameter | CNC Machining | 3D Printing |

|---|---|---|

| Process Type | Subtractive | Additive |

| Typical Tolerances | ±0.01 mm – ±0.05 mm | ±0.1 mm – ±0.3 mm |

| Surface Finish Quality | Excellent (Ra 1.6–3.2 μm) | Fair to Good |

| Material Types | Metal, Plastic, Composite | Mostly Plastic (some metal options) |

| Production Speed | Fast (1–3 days for prototypes) | Fast for simple designs |

| Mechanical Properties | Excellent (close to end-use) | Moderate (not production-grade) |

| Suitable for Functional Test | ✔ Yes | ✘ Limited |

Want more data on machining capabilities and services? Visit Boona Prototypes CNC Services for detailed specifications and case studies.

IV. Types of CNC Processes in Prototyping

-

CNC Milling – Ideal for flat surfaces, slots, pockets, and complex contours.

-

CNC Turning – Best for cylindrical shapes like shafts and bushings.

-

5-Axis Machining – Allows multi-surface operations in one setup, saving time.

-

EDM (Electrical Discharge Machining) – Used for sharp internal corners or hard metals.

V. Why CNC Machining Is Ideal for Rapid Prototyping

| Benefit | Description |

|---|---|

| High Precision | Ideal for tight-tolerance components. |

| Fast Turnaround | Prototype parts in 24–72 hours. |

| Material Flexibility | Supports aluminum, ABS, POM, stainless steel, titanium, and more. |

| Repeatable Quality | Every iteration is consistent and scalable. |

| Real-World Testing | Functional prototypes behave like production parts. |

| No Tooling Required | Eliminates cost/time of mold fabrication. |

VI. Applications Across Industries

CNC rapid prototyping is widely used in:

-

Automotive – custom brackets, engine prototypes

-

Aerospace – structural fittings, aerodynamic parts

-

Medical Devices – surgical tools, housings

-

Robotics – frames, sensor mounts

-

Consumer Electronics – enclosures, connectors

At Boona Prototypes, industry-specific experience ensures that each prototype meets relevant performance standards.

VII. Limitations to Consider

While CNC machining is powerful, it does come with certain trade-offs:

-

Higher Cost for Complex Geometries

Intricate features may require longer machining time or 5-axis machines. -

Material Waste

Subtractive nature means excess material is discarded. -

Design Constraints

Undercuts and deep cavities are harder to produce than with additive methods.

VIII. When to Choose CNC Machining for Prototypes

Opt for CNC when:

-

You need functional, production-grade prototypes.

-

Tight tolerances or high strength are required.

-

You’re creating parts from metal or engineering plastics.

-

You plan low-volume production or bridge tooling.

Final Thoughts

CNC machining is a cornerstone of rapid prototyping, particularly when speed, precision, and real-world functionality are crucial. Whether you’re designing the next-gen drone, surgical instrument, or automotive part, CNC allows you to move from concept to component—fast.

If you’re looking for a reliable CNC machining partner, explore Boona Prototypes to see how their prototyping solutions help global engineers and designers bring ideas to life.

FAQs

1. What is the difference between CNC machining and 3D printing for prototyping?

CNC machining is a subtractive process that removes material from a solid block, while 3D printing is an additive process that builds parts layer by layer. CNC offers higher strength, tighter tolerances, and a wider material selection, making it ideal for functional prototypes.

2. Why choose CNC machining for rapid prototyping?

CNC machining is preferred when your prototype requires precision, durability, and production-grade materials like aluminum or POM. It also allows fast turnaround—parts can be ready in as little as 1–3 days.

3. Which materials are most commonly used in CNC prototyping?

Popular materials include:

-

Metals: Aluminum 6061, Stainless Steel, Brass

-

Plastics: ABS, POM (Delrin), Nylon, Polycarbonate

Boona Prototypes offers a broad range of material options—learn more here.

4. What tolerances can CNC machining achieve in prototypes?

Typical tolerances for CNC prototypes range from ±0.01 mm to ±0.05 mm, depending on material, machine type, and part geometry.

5. How long does it take to get a CNC prototype?

Lead times vary by complexity, but rapid CNC machining can deliver parts within 1–5 working days, especially for simple or mid-level designs.

6. Is CNC prototyping suitable for low-volume production?

Yes, CNC machining is perfect for low-volume or bridge production because it doesn’t require tooling. It’s cost-effective for batches from 1 to 100+ units.

7. Can CNC machined prototypes be used for functional testing?

Absolutely. CNC prototypes are made from real engineering materials and often used for stress testing, assembly fitting, and performance validation.

8. What file formats are accepted for CNC machining?

Boona Prototypes and most CNC services accept:

-

3D models: STEP, IGES, STL

-

2D drawings (optional): PDF or DXF for critical dimensions

9. How does 5-axis CNC improve prototyping?

5-axis machining allows multi-angle cutting in a single setup, reducing machining time and increasing accuracy—especially for complex or curved surfaces.

10. Where can I get CNC prototypes made quickly?

Boona Prototypes is a trusted supplier offering rapid CNC machining services with fast lead times, global shipping, and engineering support.