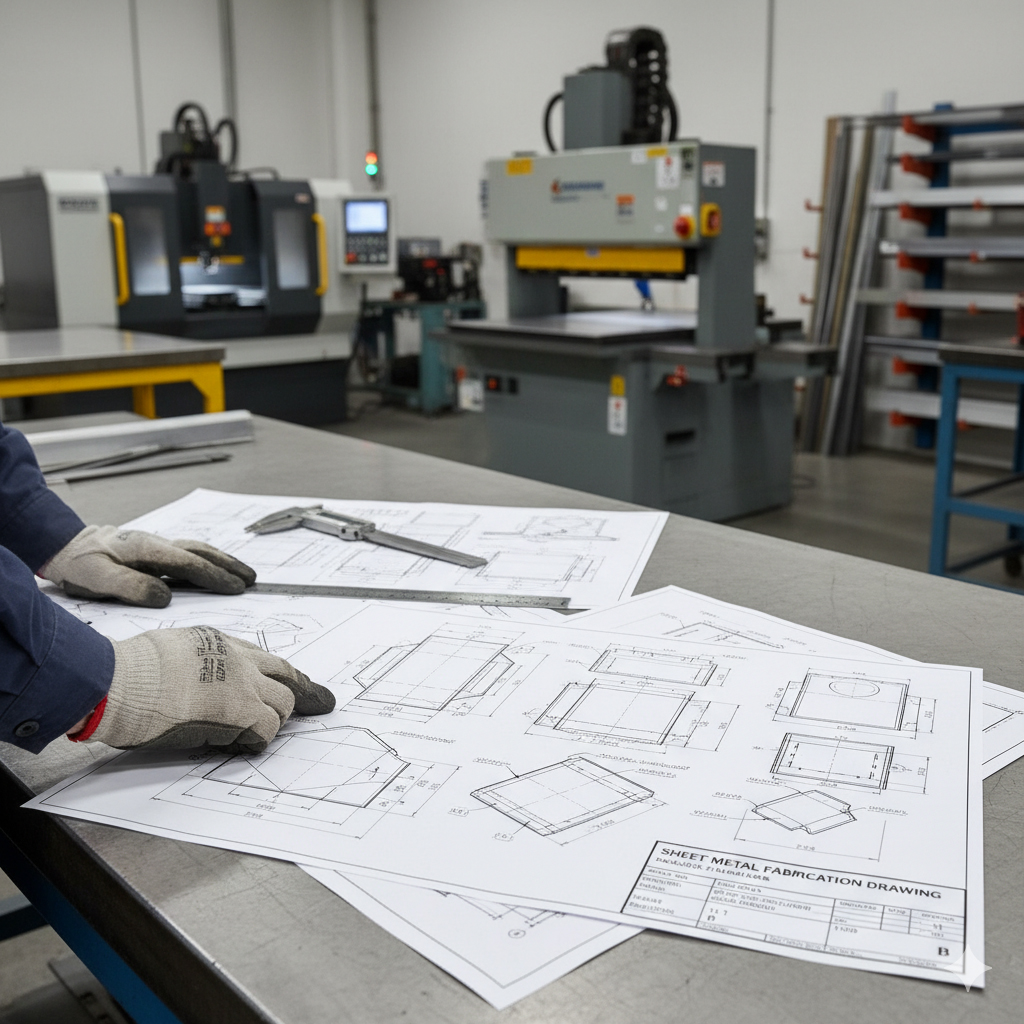

When it comes to sheet metal fabrication, an accurate understanding of engineering drawings is essential. A well-prepared drawing ensures that your product is manufactured with the right material, thickness, bends, and finishes. Misinterpretation can lead to costly mistakes, delays, or rejected parts.

This guide will walk you through the key elements of reading a sheet metal fabrication drawing, supported by technical data and insights. For professional prototyping and manufacturing support, you can explore Boona Prototypes sheet metal fabrication services.

I. Why Sheet Metal Drawings Matter

-

Clarity: Engineers and fabricators use the same language.

-

Efficiency: Reduces back-and-forth questions during production.

-

Accuracy: Ensures tolerance, bend radius, and surface finish requirements are met.

-

Cost control: Prevents rework and material waste.

II. Key Components of a Sheet Metal Fabrication Drawing

-

Title Block – Contains part name, drawing number, revision level, scale, and material specification.

-

Views – Orthographic, section, and isometric views for clarity.

-

Dimensions – Defines lengths, hole locations, bend angles, and cutouts.

-

Tolerances – Specifies allowable variation (e.g., ±0.1 mm).

-

Material Callout – Type of sheet metal, thickness, and surface treatment.

-

Bend Details – Bend radius, angle, and direction.

III. Understanding Bend Parameters

In sheet metal, bending is one of the most critical processes. Designers must account for bend allowance and K-factor to ensure correct part dimensions.

Here’s a reference table:

| Material | Thickness (mm) | Minimum Bend Radius (mm) | Typical K-Factor | Notes |

|---|---|---|---|---|

| Aluminum 5052 | 1.0 | 1.0 × Thickness | 0.33 | Good formability |

| Stainless Steel 304 | 1.5 | 1.5 × Thickness | 0.40 | Requires higher force |

| Mild Steel | 2.0 | 1.0 × Thickness | 0.35 | Economical and common |

| Copper | 1.0 | 0.8 × Thickness | 0.30 | Very ductile |

Tip: Always check your manufacturer’s capabilities. For example, Boona Prototypes offers precision bending with strict tolerance control.

IV. Tolerances in Sheet Metal Drawings

Tolerances define how much deviation is allowed. Tight tolerances increase cost, while loose tolerances risk poor assembly.

| Feature | Standard Tolerance (ISO 2768-m) | Example |

|---|---|---|

| Linear Dimension (≤30 mm) | ±0.1 mm | Hole location |

| Linear Dimension (30–120 mm) | ±0.2 mm | Slot length |

| Bending Angle | ±1° | Bracket bend |

| Hole Diameter | ±0.1 mm | Fastener fit |

For more on how tolerances affect manufacturability, you can explore the CNC machining and fabrication services offered by Boona.

V. Interpreting Symbols and Notes

-

Weld symbols – Indicate weld type and location.

-

Surface finish symbols – Define polishing, coating, or painting.

-

Countersink/counterbore notes – Required for fastener compatibility.

VI. Manufacturability Considerations

A good drawing not only communicates design intent but also ensures the part can be manufactured cost-effectively.

Checklist:

-

Avoid very tight bend radii on thick materials.

-

Allow adequate clearance for punch tools.

-

Consider sheet thickness variation in forming.

-

Specify finishes (anodizing, powder coating, passivation).

For design-for-manufacturing (DFM) feedback, Boona Prototypes provides engineering consultation to optimize your drawings before production.

VII. Example: Reading a Simple Sheet Metal Drawing

Imagine a bracket with two bends and three holes:

-

Material: Aluminum 5052, 2.0 mm thickness.

-

Dimensions: 100 × 50 × 30 mm with ±0.2 mm tolerance.

-

Bend radius: 2 mm (equal to thickness).

-

Holes: Ø8 mm ±0.1 mm, positioned 20 mm from edge.

-

Finish: Anodized, matte black.

A manufacturer like Boona Prototypes would use a press brake to form the bends and CNC punching/laser cutting for holes.

Conclusion

Reading and understanding sheet metal fabrication drawings is a vital skill for engineers, designers, and manufacturers. By mastering dimensions, tolerances, bend parameters, and finish specifications, you can ensure accurate, cost-efficient production.

For reliable prototyping and production, consider partnering with Boona Prototypes—a trusted expert in sheet metal fabrication, CNC machining, and rapid prototyping services.

FAQs

1. What is a sheet metal fabrication drawing?

A sheet metal fabrication drawing is a technical blueprint that shows the geometry, dimensions, tolerances, materials, and finishes required to manufacture a part. It helps fabricators produce the part accurately according to design intent.

2. Why is it important to understand sheet metal drawings?

Misinterpreting a drawing can lead to incorrect dimensions, poor fit, or costly rework. Clear understanding ensures efficiency, quality, and cost savings during fabrication.

3. What should I look for first in a sheet metal drawing?

Start with the title block, which lists critical details like material, thickness, finish, and revision level. Then review dimensions, tolerances, and bend details to fully understand the design.

4. What is the role of bend radius and K-factor in sheet metal drawings?

The bend radius determines how tightly the sheet can be bent without cracking. The K-factor accounts for material stretch during bending, ensuring the final part dimensions are accurate.

5. How are tolerances defined in sheet metal drawings?

Tolerances specify acceptable variation from nominal dimensions. For example, a hole diameter of Ø10 mm ±0.1 mm means the hole can be between 9.9 mm and 10.1 mm.

6. Can I use a 3D CAD file instead of a 2D drawing?

Yes, 3D CAD files are widely used, but most manufacturers still require a 2D drawing for final reference. The 2D drawing serves as a legal document and contains critical notes not always in CAD models.

7. What happens if the drawing is unclear or incomplete?

Fabricators may request clarification, which delays production. In the worst case, the part may be made incorrectly. That’s why clear notes, tolerances, and views are essential.

8. How do surface finish symbols affect sheet metal parts?

Surface finish instructions indicate treatments like anodizing, powder coating, or polishing. They directly impact appearance, corrosion resistance, and performance.

9. Do all manufacturers follow the same drawing standards?

Most use international standards such as ISO, ASME, or DIN. However, some regions or companies may have unique symbols or tolerance practices. Always confirm with your chosen fabricator.

10. Where can I get help interpreting or preparing sheet metal drawings?

You can work with experienced manufacturers like Boona Prototypes, who provide engineering consultation and DFM (Design for Manufacturing) feedback to ensure your drawings are production-ready.